Differential Thermal Analyser. D.T.A

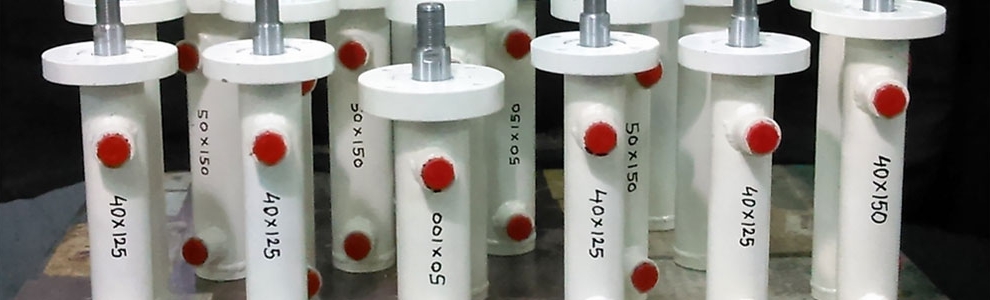

Manufacturer & Exporter of Differential Thermal Analyser. D.T.A. Our product range also comprises of Hydraulic and Pneumatic Cylinders, Hydraulic Power Pack Unit and Rotary Actuator.

Hydraulic and Pneumatic Presses

Differential thermal analysis is a simple but powerful thermo analytical technique which can be employed to study the variety of physical and chemical transformations in materials subjected to programmed heating in controlled ambient gaseous environment. Some of the most common transformations in materials include physical change of state like fusion(melting), polymorphic transformations ( change of crystal structure) and thermal decomposition involving dehydration and thermal degradation of materials the typical example of chemical transformation and thermal decomposition of materials like copper sulphate, penta-hydrate and thermal decomposition of calcium carbonate and degradation of polymers on heating. The technique involves measurement of temperature difference between the sample unit, investigation and thermally inert reference material (generally calcined alumina) located in the uniform temperature zone of the furnace which is heated at the programmed per-determined heating rate. The plot of temperature difference between the sample and the reference material yields a peak corresponding to the physical or chemical transformation. The temperature difference (expressed in micro volts) between the sample and the reference material is zero till the transformation in the material is initiated. The departure of the signal from zero baseline is an indication of the beginning of physical or chemical transformation in the material. Fig 1 presents the schematic of the principle of data and the type of plot for an hypothetical transformation in the material subjected to uniform heating. The first transformation involves absorption of heat and the second involves evolution. The base line returns to zero,(ideally) on completion of the transformation.

The instrument available has the following features :

- A programmable tubular furnace capable of heating upto 1100 degc at the programmed rate of heating from 1 to 10 degc/min.

- A reaction chamber made of none end closed silica tube and reference material in two identical sample holders in uniform temperature zone.

- Two thermocouples to monitor the temperature of the sample and reference material subjected to programmed heating rate.

- The flow meter to regulate the rate of flow of gases in the reaction chamber at different flow rate.

The data recorded on some typical systems involving dehydration, fusion and thermal degradation are present in the figures along with the experimental conditions employed. The instrument can be used to determine the temperatures of physical and chemical transformations in the material such a melting point and decomposition temperatures. It is also possible to obtain the energy associated with such transformations from the area under the curve, albeit with some reservations. The instrument can also be employed for the study of phase transformations and delineation of phase boundaries. The apparent values of rate determining parameters for the solid state transformations can also be derived from these curves