Our Infrastructure

Our Equipments

CNC Punching

Our 2008 Boschert CNC Punching machine with 1250 x 4000 mm sheet capacity is the newest punching technology available. The advantage of the new CNC punch is the greatly enhance speed and accuracy, higher output and lower cost. The punch has capabilities of simple forming, de-burring, embossing, flaring beading and lights out operation.

Our 2008 Boschert CNC Punching machine with 1250 x 4000 mm sheet capacity is the newest punching technology available. The advantage of the new CNC punch is the greatly enhance speed and accuracy, higher output and lower cost. The punch has capabilities of simple forming, de-burring, embossing, flaring beading and lights out operation.

Material Size Capacity:

Our punching machine handle sheet sizes up to 1250 x 4000 mm.

• Mild steel (cold rolled and hot rolled) 6.0 mm thick

• Aluminum, Copper and Brass sheet 6.0 mm thick

• Stainless steel sheet 6.0 mm thick

Laser Cutting

Our CNC Trumpf laser-cutting department provides a large range of capabilities, ensuring the needs of our customers are met with quality and competitive costs. Laser cutting is effective for parts with contours, low productions quantities, and smooth edges. Trumpf TLF3030: 4000 Watt CO2 Laser with 1500 x 3000 mm bed and pallet changer enables us to produce parts with no sheet loading and unloading time. Also the machine has Rotation attachment (Rota-Las) for Tube cutting of Round, Square and Rectangular cross section with Ø300 X 10 mm thk. with 3000 mm in length.

Our CNC Trumpf laser-cutting department provides a large range of capabilities, ensuring the needs of our customers are met with quality and competitive costs. Laser cutting is effective for parts with contours, low productions quantities, and smooth edges. Trumpf TLF3030: 4000 Watt CO2 Laser with 1500 x 3000 mm bed and pallet changer enables us to produce parts with no sheet loading and unloading time. Also the machine has Rotation attachment (Rota-Las) for Tube cutting of Round, Square and Rectangular cross section with Ø300 X 10 mm thk. with 3000 mm in length.

Material Size Capacity

Our laser cutting can handle sheet sizes up to 1500 x 3000

• Mild steel (cold rolled and hot rolled) 20mm thick

• Aluminum sheet 10 mm thick

• Stainless steel sheet 15mm thick

Forming

Our sheet metal forming department consists of 5-Axis press brakes with diverse capabilities and over 15 years of combined experience of our fabrication team members, ensuring our customers high quality forming at competitive costs. The software has a unique capabilities deciding bend sequence to get 100% ok job at very 1st try.

Our sheet metal forming department consists of 5-Axis press brakes with diverse capabilities and over 15 years of combined experience of our fabrication team members, ensuring our customers high quality forming at competitive costs. The software has a unique capabilities deciding bend sequence to get 100% ok job at very 1st try.

Material Size Capacity:

Our CNC press brake can handle sheet size up to 1500 x 3000 x 8 mm

• Boschert 3175: 175 Ton , 5-axis , 3100 mm CNC Press Brake

• Mild Steel 8 mm

• Aluminium 10 mm

• Stainless Steel 6 mm

Welding

• MIG Welding 4 nos.

• TIG Welding 3 nos. for SS.

• CD Projection Welding for Stud/Nut.

• Weltronic 32 KVA Resistance Spotwelder.

• Thick welding with Arc Welding & Co2 welding.

Hardware Insertion

• Manual Rivet nut/Stud from PEM and Kerb Konus Type (Supporting Facilities)

• Hager Press 8 ton 24" Throat with Auto-feed. (Planned to install as per product need.)

Hi-frequency Ultrasonic cleaning

For absolutely Oil free and dust free component specially for stainless steel. (Millipore value=5mg).

Assembly

• 2,000 sq ft of Mechanical Assembly Bench Area.

• Assorted Pneumatic Hand Tools for Mechanical Assembly.

Processing

• Lead times are dependent on customer needs.

• Delivery either by our trucks, common carrier, or freight trucking.

• Outside processes include: Powder coating, Aluminum Anodizing and Stainless Steel Name plate, Anodizing, Machining, Polishing, Etching and Engraving.

Applications

• Cabinets

• Enclosures

• Panels

• Brackets

• Chassis

• Boxes

• Machine Guards and subcomponents

• Assemblies

• Junction Boxes

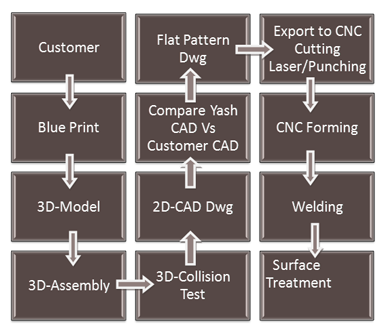

Product Development Process