Sheet Metal Fabrication

Our Sheet metal fabrication process ensures our customers on-time deliveries and cost effective pricing, while maintaining quality requirements the customers blue prints specify. We invest in the latest technology to ensure we maintain a competitive edge on cost, quality, and lead-time. The parts manufactured at Yash Lasertek India Pvt.Ltd. are studied thoroughly at every process from of the quote, through production, assembly, packing and shipping. Our capabilities range from design enhancement, programming, laser cutting, punching, surface finishing, press brake, hardware insertion, welding, grinding, de-burring, screen-printing, assembly and packaging.

Our Sheet metal fabrication process ensures our customers on-time deliveries and cost effective pricing, while maintaining quality requirements the customers blue prints specify. We invest in the latest technology to ensure we maintain a competitive edge on cost, quality, and lead-time. The parts manufactured at Yash Lasertek India Pvt.Ltd. are studied thoroughly at every process from of the quote, through production, assembly, packing and shipping. Our capabilities range from design enhancement, programming, laser cutting, punching, surface finishing, press brake, hardware insertion, welding, grinding, de-burring, screen-printing, assembly and packaging.

Our Standard Material Include:

Aluminum, Steel, Stainless Steel, Galvanized, Copper.

Material thickness ranges from 0.50mm to 20.0mm depending on the materials used.

RoHS compliant on some of the materials we use.

Material certifications available upon request.

Sheet Metal Design

Our engineers partner with our customers to modify sheet metal designs for fabrication efficiency resulting in lower manufacturing costs. Whether you have complete blueprints, a basic concept design that needs drawings, or have a part and need reverse engineering, our engineers can work with you streamline the design for the most cost efficient fabrication process. Our engineers will work with your organization on-site as required to provide support for your needs.

Our engineers partner with our customers to modify sheet metal designs for fabrication efficiency resulting in lower manufacturing costs. Whether you have complete blueprints, a basic concept design that needs drawings, or have a part and need reverse engineering, our engineers can work with you streamline the design for the most cost efficient fabrication process. Our engineers will work with your organization on-site as required to provide support for your needs.

Our Standard Materials Include:

Aluminum, Steel, Stainless Steel, Galvanized, Copper.

Material thickness ranges from 0.5 to 20 mm depending on the materials used.

RoHS compliant on some of the materials we use.

Material certifications available upon request

Capabilities:

Engineering:

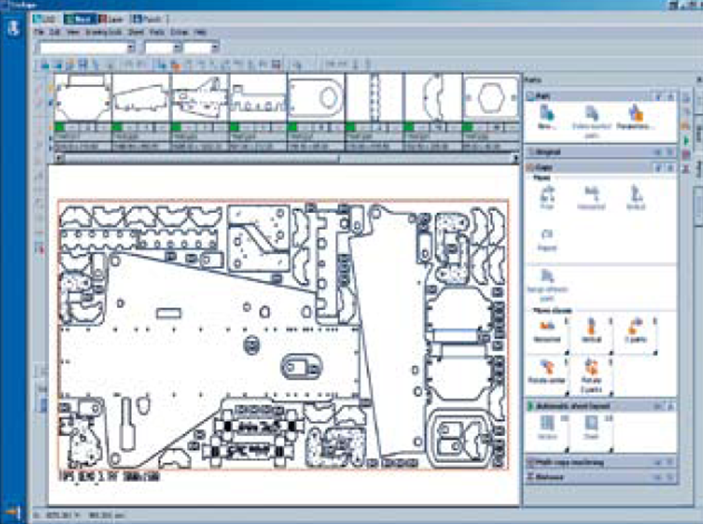

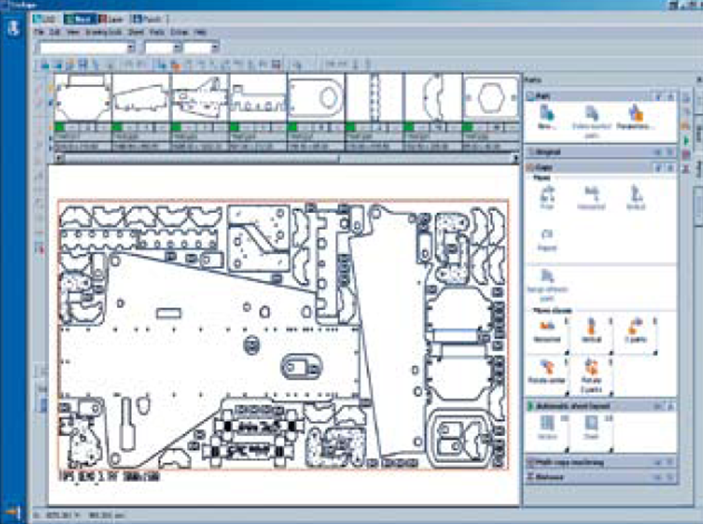

Trumpf TruTops CNC programming software for CNC Laser cutting

Auto CAD,Trueshape Nesting for 2D Design.

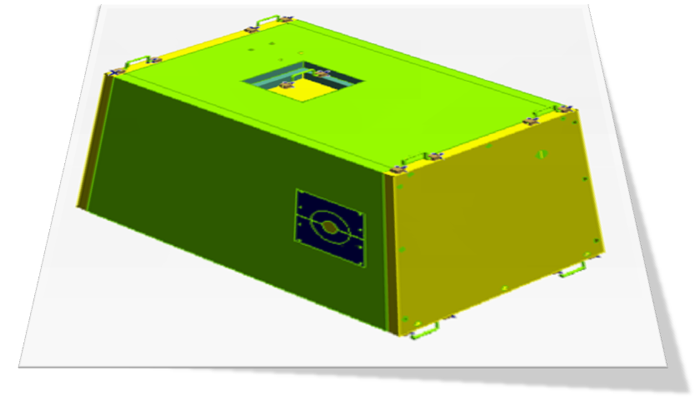

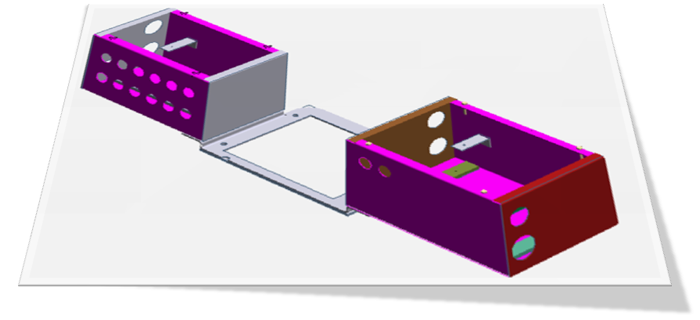

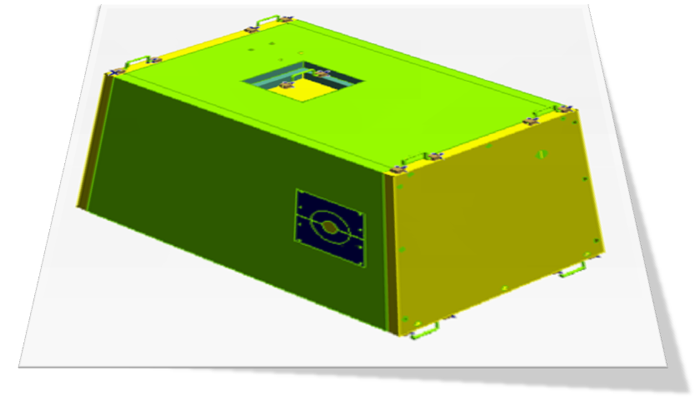

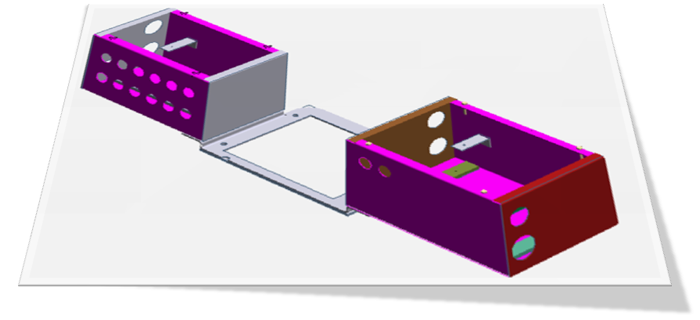

Think3 for 3D surfacing ,Solid modeling ,Flat pattern and animation.

Radan for CNC programming software for CNC Punching,3D modeling and true shape nesting.

Metalix for CNC programming software for CNC Punching,3D modeling and true shape nesting.

All DESIGN Software are with License Copy of Yash Lasertek India Pvt.Ltd. ownership.

True Shape Nesting:

For optimum utilization of material.

3D Modeling

CNC Punching

New in 2008, our Boschert Rotation doubled our CNC punching capacity and expanded our fabrication capabilities. Coupled with our Laser cutting machine Y1 Manufacturing has the capacity to exceed our customers needs. Not only does the Boschert provide unimaginable speed and accuracy, the CNC sheet metal punch also had the added capabilities of simple forming, beading. The ability to run lights out increases our capacity and allows us to meet our customers increasing needs. We invest in the latest technology to ensure we maintain a competitive edge on cost, quality, and lead-time.

New in 2008, our Boschert Rotation doubled our CNC punching capacity and expanded our fabrication capabilities. Coupled with our Laser cutting machine Y1 Manufacturing has the capacity to exceed our customers needs. Not only does the Boschert provide unimaginable speed and accuracy, the CNC sheet metal punch also had the added capabilities of simple forming, beading. The ability to run lights out increases our capacity and allows us to meet our customers increasing needs. We invest in the latest technology to ensure we maintain a competitive edge on cost, quality, and lead-time.

Our Standard Materials Include:

Aluminum, Steel, Stainless Steel, Galvanized, Copper, Brass.

Material thickness ranges from 0.5 to 6.0mm depending on the materials used.

RoHS compliant on some of the materials we use.

Material certifications available upon request.

Capabilities:

CNC Punching:

Boschert Rotation CNC Punching Center can handle 1250 x 4000 mm sheet.

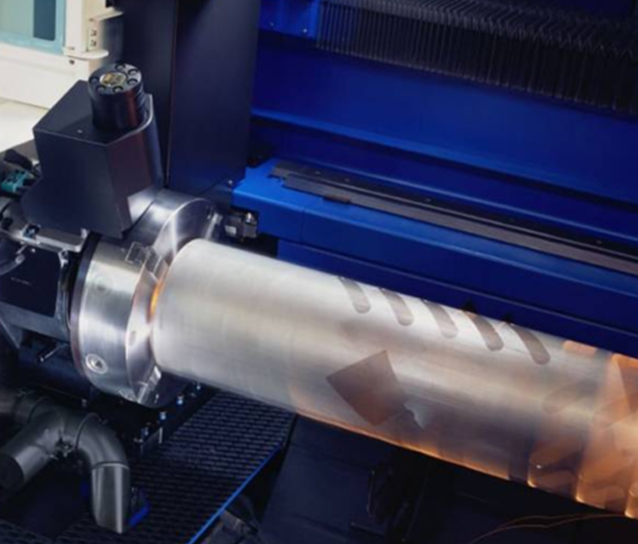

CNC Laser Cutting

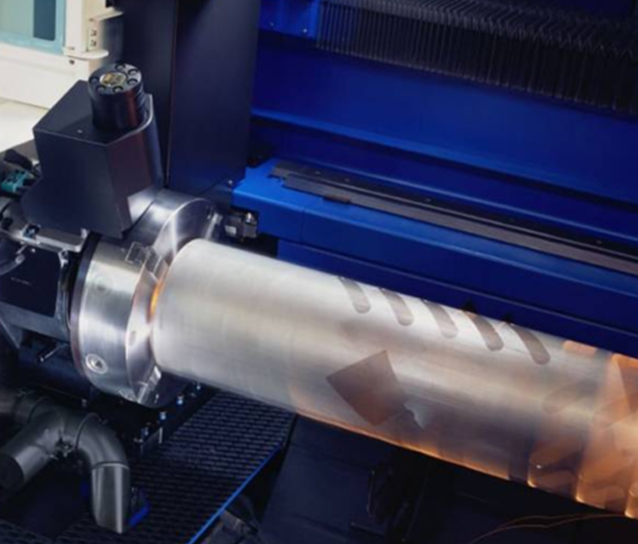

Our CNC Trumpf laser-cutting department provides a large range of capabilities, ensuring the needs of our customers are met with quality and competitive costs. Laser cutting is effective for parts with contours, low productions quantities, and smooth edges. We utilize our high-speed CNC punches in combination with our lasers to increase production efficiency. Parts with many holes are punched first, and then the odd hole sizes and contoured edges are laser cut. The real advantage of a punch/laser combination is a reduction to the cost of parts. Also, with Trumpf Tech center only 45 minutes away, we have all their training and technical support at our door-step. We invest in the latest technology to ensure we maintain a competitive edge on cost, quality, and lead-time.

Our Standard Materials Include:

Aluminum, Steel, Stainless Steel, Galvanized and Copper.

Material thickness ranges from 0.5 to 20.0mm depending on the materials used.

Rohs compliant on some of the materials we use.

Material certifications available upon request.

Capabilities

CNC Laser Cutting

CNC Laser Cutting

Trumpf TL3030: 4000 Watt , CO2 Laser with

1500 X 3000 bed and pallet changer

Flat sheet Cutting :

Flat sheet Cutting :

CNC Tube Laser Cutting :

CNC Tube Laser Cutting :

Sheet Metal Forming

Our sheet metal forming department consists of 5-Axis press brakes with diverse capabilities and over 15 years of combined experience of our fabrication team members, ensuring our customers high quality forming at competitive costs. The software has a unique capabilities deciding bend sequence to get 100% ok job at very 1st try. Our press brakes handle sheet sizes up to 3000mm in length and have the capably of bending material ranging from 0.3 to 12mm thick depending on tonnage requirements. Setup programs are stored at the press brake and quickly recalled to speed the setup of repeat jobs. We have an extensive tooling inventory to meet most needs and can develop custom tooling as necessary.

Our sheet metal forming department consists of 5-Axis press brakes with diverse capabilities and over 15 years of combined experience of our fabrication team members, ensuring our customers high quality forming at competitive costs. The software has a unique capabilities deciding bend sequence to get 100% ok job at very 1st try. Our press brakes handle sheet sizes up to 3000mm in length and have the capably of bending material ranging from 0.3 to 12mm thick depending on tonnage requirements. Setup programs are stored at the press brake and quickly recalled to speed the setup of repeat jobs. We have an extensive tooling inventory to meet most needs and can develop custom tooling as necessary.

Our Standard Materials Include:

Aluminum, Steel, Stainless Steel, Galva-annealed, Galvanized, Copper, Brass.

Material thickness ranges from 0.3mm to 12mm depending on the materials used.

RoHS compliant on some of the materials we use.

Material certifications available upon request.

Capabilities

CNC Press Brake

Our CNC forming has multi-axes press brake capabilities, which increase speed and accuracy, lowers costs, and improves quality.

CNC Shearing

The shearing machine has unique features . The CNC controlled back gauge gets positioned to the programmed size within 0.05mm repeatability and can shear within 0.3mm in 3000mm length. Also the gap between the blades (clearance) is CNC controlled and gets adjusted to the required size according to the sheet thickness in program. This gives a clean cut absolutely burr free. Thus the unique features of the machine and combined experience of our fabrication team members, ensuring our customers high quality at competitive costs. The sensors in the machine can detect the wrong thickness sheet if ever fed by the operator before it cuts the sheet. This all advantages leads us towards ON TIME deliveries and avoids any machine breakdowns .The shearing machine can handle sheet sizes up to 3000mm in length and have the capability of shearing material ranging from 0.3 to 10mm thickness. ts. Setup programs @ 100 sizes are stored at the shearing machine controller and quickly recalled to speed the setup of repeat jobs.

The shearing machine has unique features . The CNC controlled back gauge gets positioned to the programmed size within 0.05mm repeatability and can shear within 0.3mm in 3000mm length. Also the gap between the blades (clearance) is CNC controlled and gets adjusted to the required size according to the sheet thickness in program. This gives a clean cut absolutely burr free. Thus the unique features of the machine and combined experience of our fabrication team members, ensuring our customers high quality at competitive costs. The sensors in the machine can detect the wrong thickness sheet if ever fed by the operator before it cuts the sheet. This all advantages leads us towards ON TIME deliveries and avoids any machine breakdowns .The shearing machine can handle sheet sizes up to 3000mm in length and have the capability of shearing material ranging from 0.3 to 10mm thickness. ts. Setup programs @ 100 sizes are stored at the shearing machine controller and quickly recalled to speed the setup of repeat jobs.

Our Standard Materials Include:

Aluminum, Steel, Stainless Steel, Galva-annealed, Galvanized, Copper, Brass.

Material thickness ranges from 0.3mm to 10mm depending on the materials used.

RoHS compliant on some of the materials we use.

Material certifications available upon request.

Capabilities

CNC Shearing

Our CNC Shearing machine burr free and highly shearing accuracy capabilities, which increase speed and accuracy, lowers costs, and improves quality.

Our Sheet metal fabrication process ensures our customers on-time deliveries and cost effective pricing, while maintaining quality requirements the customers blue prints specify. We invest in the latest technology to ensure we maintain a competitive edge on cost, quality, and lead-time. The parts manufactured at Yash Lasertek India Pvt.Ltd. are studied thoroughly at every process from of the quote, through production, assembly, packing and shipping. Our capabilities range from design enhancement, programming, laser cutting, punching, surface finishing, press brake, hardware insertion, welding, grinding, de-burring, screen-printing, assembly and packaging.

Our Sheet metal fabrication process ensures our customers on-time deliveries and cost effective pricing, while maintaining quality requirements the customers blue prints specify. We invest in the latest technology to ensure we maintain a competitive edge on cost, quality, and lead-time. The parts manufactured at Yash Lasertek India Pvt.Ltd. are studied thoroughly at every process from of the quote, through production, assembly, packing and shipping. Our capabilities range from design enhancement, programming, laser cutting, punching, surface finishing, press brake, hardware insertion, welding, grinding, de-burring, screen-printing, assembly and packaging.