Our Products

- Chapatti Making Machine(L-Shape)

- Chapatti Making Machine ( Automatic Chapatti Making Machine)

- Semi Automatic Chapatti Making Single Unit with Oven Machine Capacity 900/Hr

- Single Unit Semi- Automatic Chapatti Making Machine

- Atta Kneating Machine

- Dough Ball/ Peda Making Machine

- LPG Chapatti Oven

- Cone Making Machine

- Electric Chapatti Oven

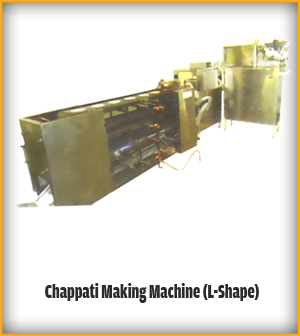

Chappati Making Machine (L-Shape)

ROLLER MODEL (PEDA TYPE) CAPACITY:-750 & 1200-1500/HR + 2400 HR and M.S. frame stainless steel covering

The machine is in 3 parts:- PEDA making & one rolling machine is fitted with one motor of 1 HP Single phase and one gear box. Second Rolling machine and baking oven is fitted with one motor of 1 HP single phase and one gear box. Food grade conveyors in the rolling machines. Stainless steel rollers of rolling machines. Stainless steel Conveyor 304 of the baking oven. Chapatti baking oven is 3 tier. RV burners for baking and round burners below the stainless steel wire mesh for puffing. Weight, thickness & size of the chapatti can be adjusted from 4”t06”. It is installed in L shape.

- CAPACITY:- 750 Chapattis/hr.

- SIZE:- 5ft & 9ft. X 2.5ft, LPG consumption (5kg./hr(approx)

- WORKING:- Switch the backing oven on. The conveyor will start moving. Light up the LPG burners. Let the oven get heated for 8 minutes. Put kneaded dough into the hopper of the PEDA making machine and dry ATTA into both the hoppers of the sprinklers of chapatti rolling machine, which will continuously keep sprinkling on the conveyor to avoid sticking of ATTA on the conveyor or the rollers. Dough balls will fall automatically on the first rolling machine, which will carry the dough ball into the roller, flattening into oval shape. The oval piece will than fall on the conveyor of the second rolling machine, which will flatten it from the other side making it round. The round piece will than fall on the conveyor off.