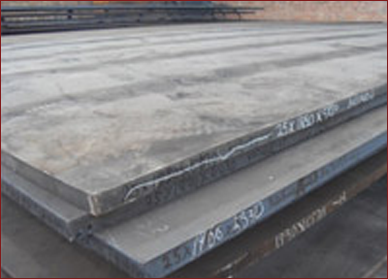

Manganese Steel Plates

Manganese Steel Plates are known as one the toughest kind of steels available in the market. The plates are abrasion resistant and posses an excellent metal work hardening capability. Ideal for wearing plates for strengthening process, these manganese steel grades are widely demanded in various industries. Owing to its maximum wear resistant life, these plates are widely used in conveyor parts, grizzly bar, truck bed bodies and more.

The main property of manganese steel sheets is that, it contains 12%-14% of manganese steel. Due to this toughness, these steel plates are able to absorb shock leads safely. The best part about these non magnetic plates is that during the work hardening process only the outer surface hardens. While the inner layer remains highly ductile.

Available range : Hadfield Manganese Plate & High Manganese Steel Plate

Features Highly ductile, Non-magnetic properties, High tensile strength, Great welding ability and High abrasion resistance

Widely known for its work hardening properties, Hadfield Manganese Plate is amenable to high-impact wear applications or those in which scratch abrasion is encountered. This steel plate enhances almost five times the hardness of mild steel and almost three times the hardness of annealed stainless steel. Due to this, one can enjoy a longer lifespan and extended protection of their equipment and facilities.

High Manganese Steel Plate

High Manganese Steel Plate is a non-magnetic and work hardening type of steel which thrives on severe wear conditions. The best thing about this kind of plate is that, the more impact and hammering it receives, the harder its surface becomes. This is a complete austenitic quench annealed non-magnetic work-hardening steel which offers an extremely high level of wear resistance when subjected to work.