Abrasion Resistant Plates

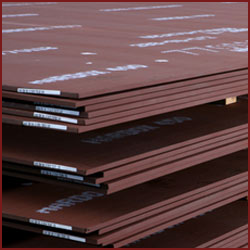

Abrasion Resistant Plates/ AR (Abrasion Resistant) Steel Plates are used to fabricate of numerous products such as conveyors, chutes & liners and aggregate containers. Our strong association with trustworthy vendors enables us to offer these plates according to specifications laid down by our valuable clients. These are widely demanded by clients owing to its high strength, durable performance and rugged construction Apart from this, these plates exhibit an excellent combination of high resistance to impact, workability, weld ability and resistance to abrasion.

Available range : Hardox Plates, Hardox 400 Plates & Hardox 500 Plate

Applications : Mining And Quarrying, Process Industries, Material Handling And Construction, And Earthmoving

Hardox Plates

Hardox Plates are also known as wear plates which are designed to last longer than standard mild steel. The most common hardness levels in the category are 400 and 500. The combination of hardness, strength and toughness makes it stand up to extreme wear. This can replace expensive wear products like high chrome white iron and hard-faced overlay plates. Even though it is too tough, it can be cut, welded, milled and drilled using standard workshop practices.

Hardox Plates are also known as wear plates which are designed to last longer than standard mild steel. The most common hardness levels in the category are 400 and 500. The combination of hardness, strength and toughness makes it stand up to extreme wear. This can replace expensive wear products like high chrome white iron and hard-faced overlay plates. Even though it is too tough, it can be cut, welded, milled and drilled using standard workshop practices.

Features

• Excellent Cold Bending & Welding Properties

• Through Hardened for Long Wear Life

• Flat Clean, Shot Blasted and Primed Finished Products

• High Impact Properties

• Grain-Refined

Application

• Dump Truck Bodies

• Conveyors

• Chutes

• Loading Buckets & Bulldozers

• Crushers

• Mining

• Recycling Equipment

• Lifting and Agricultural Equipment manufacturing

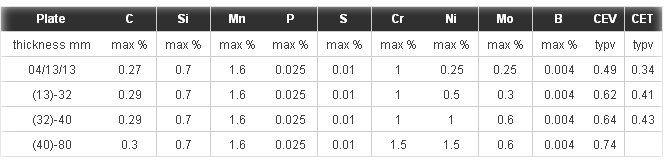

Hardox 400 Plates

Hardox Plates are also known as wear plates which are designed to last longer than standard mild steel. The most common hardness levels in the category are 400 and 500. The combination of hardness, strength and toughness makes it stand up to extreme wear. This can replace expensive wear products like high chrome white iron and hard-faced overlay plates. Even though it is too tough, it can be cut, welded, milled and drilled using standard workshop practices.

Hardox Plates are also known as wear plates which are designed to last longer than standard mild steel. The most common hardness levels in the category are 400 and 500. The combination of hardness, strength and toughness makes it stand up to extreme wear. This can replace expensive wear products like high chrome white iron and hard-faced overlay plates. Even though it is too tough, it can be cut, welded, milled and drilled using standard workshop practices.

Features

• Excellent Cold Bending & Welding Properties

• Through Hardened for Long Wear Life

• Flat Clean, Shot Blasted and Primed Finished Products

• High Impact Properties

• Grain-Refined

Application

• Dump Truck Bodies

• Conveyors

• Chutes

• Loading Buckets & Bulldozers

• Crushers

• Mining

• Recycling Equipment

• Lifting and Agricultural Equipment manufacturing

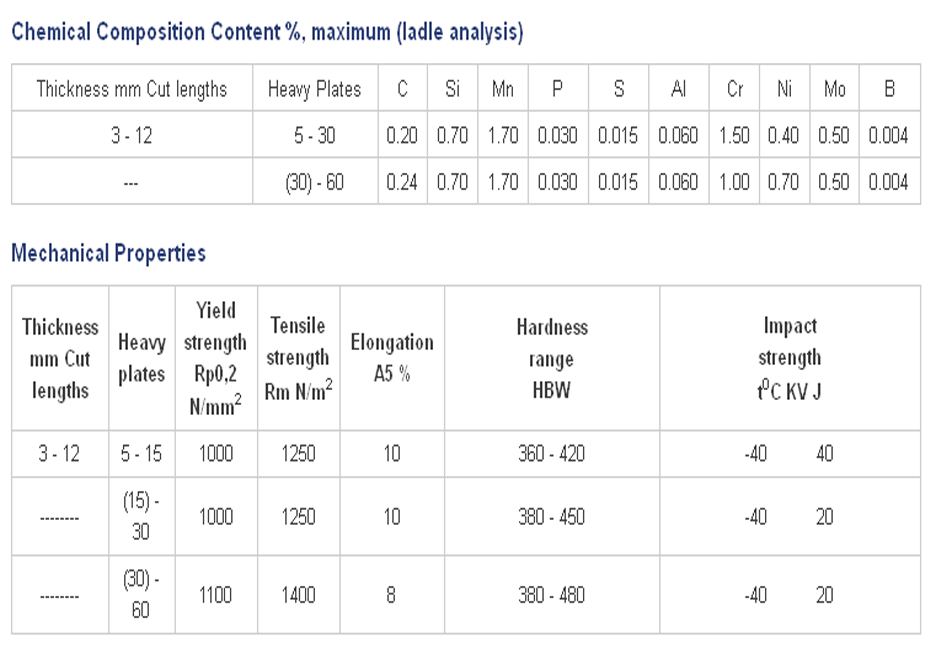

Hardox 500 Plates

Hardox 500 Plate can easily be bended and welded. These plates are resistant to abrasion and is widely used in various applications that require higher wear resistance. Further, the plates are designed with a hardness of 500 HBW for applications where demands are imposed on abrasion resistance in combination with good cold bending properties. Our respected clients can also avail this range in various sizes and finishes as per their requirements.

Hardox 500 Plate can easily be bended and welded. These plates are resistant to abrasion and is widely used in various applications that require higher wear resistance. Further, the plates are designed with a hardness of 500 HBW for applications where demands are imposed on abrasion resistance in combination with good cold bending properties. Our respected clients can also avail this range in various sizes and finishes as per their requirements.

Features

• Abrasion resistance

• Welding ability

• Wear resistant

• High tensile strength

Application

• Buffer bins

• Grizzly bars

• Measuring bins and Skips

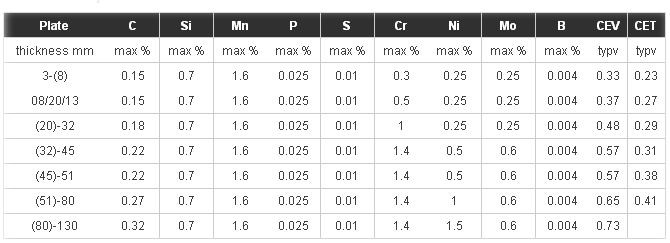

Chemical Compositions