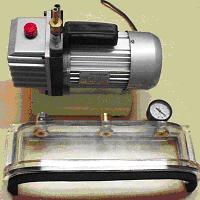

The system is used to check the leak on tank surface, butt welds on flat surface, fillet welds on corners etc.

The system is used to check the leak on tank surface, butt welds on flat surface, fillet welds on corners etc.

Consists of following :

Vacuum Pump

Connecting hose

Acrylic see through vacuum boxes

Vacuum Gauges

Quick Release Valve

Dimensions of Vacuum Boxes:

1] Flat Surface Box :

Dimensions : 325 X 200 X 70 mm

2] Corner Box :

Dimensions : 325 X 100 X 70 mm

Complete set with 2 nos of vacuum Boxes

NOTE : Custom designed vacuum boxes can be supplied against your specific requirement. Please let us know the design of your joint in order that we can offer a suitable vacuum box.

Model : Ultrasonic Leak Detector Model : LDE – 10

Model : Ultrasonic Leak Detector Model : LDE – 10

Features :

• Control of tightness, location of leaks, electrical discharge and other ultrasonic sources

• Leaks in pressure and vacuum systems

• Electrical discharge

• Control of tightness with optional ultrasonic transmitter

• Internal leaks in hydraulic systems

• Function control of steam traps

Ultrasonic Leak Detection Principle

As a gas or liquid passes through a small restrictive opening, noise is created. While this noise is imperceptible to the ear, it is very easily located by the Model LDE-10 using the ultrasonic microphone or optional ultrasonic probes. The ultrasonic signal strength is indicated by an LED-array and an audible tone through the earphone headset. As the instrument is moved closer to the ultrasonic source, more LED's will light up. Simultaneously, the frequency of the tone rises. The optional LDF-13 ultrasonic transmitter is ideal for checking tightness control in non-pressurized compartments such as containers, tanks, cars, ships, etc. The transmitter is placed inside the compartment under investigation and switched on to emit an ultrasonic signal. This signal will pass through any orifice or faulty seal and will be quickly located by the LDE-10. Accessories include the ELT-10 probe set with two insertion style probes (11.4" and 2.4") useful for internal leaks in hydraulic systems or function control of steam traps, and a remote probe with cable. The instrument is very easy to use and requires no special training or skills.

Equipment includes ultrasonic microphone, earphone headset, extension tube, battery, carrying case and manual.

Specifications :

LDE-10 Ultrasonic Leak Detector

Indicators : LED-array visible and VCO 0-5 KHz audible

Sensitivity : Adjustable 50 dB

Min. Detectable Sound Pressure :1 n bar in the 25-40 KHz range

Housing : ABS moulding

Temp Range : 32-130 deg F Power: One 9V battery

Size/Weight : 8.5" x 2" x 1.6"/ 1.2 Kgs.

LDF-13 Ultrasonic Transmitter

Frequency : 35 KHz

Power : one 9V battery (included)

For checking pin – holes/ Holidays in coatings on pipes. Portable equipment works on built in chargeable batteries. Consists of main portable equipment with shoulder carrying case, Brush probe with extension rod, Spring probe, Earth lead Battery charger and spare battery.

For checking pin – holes/ Holidays in coatings on pipes. Portable equipment works on built in chargeable batteries. Consists of main portable equipment with shoulder carrying case, Brush probe with extension rod, Spring probe, Earth lead Battery charger and spare battery.

Recommended voltage for standard pipe coatings :

Test Voltage Coating Thickness

0.5 – 5 kV 10 microns – 5-microns

10 – 20KV 20 microns-6.5mm

10-30KV 30 microns-15 mm

10-40KV 70 microns-26 mm

Model Voltage

HD-20 1.0-2.0 kV

HD-30 2.0-30kV

HD-40 2.0-40kV

Spring Electrodes

Spare Spring Electrodes for pipes of various sizes available. Size : From diameter 200 mm to 800 mm.