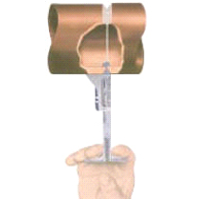

GAL HI-LO Gauges measure internal alignment of pipe after fit-up/alignment, cuts radiographic rejects.

GAL HI-LO Gauges measure internal alignment of pipe after fit-up/alignment, cuts radiographic rejects.

Measure internal misalignment of pipe before and after tacking.

For accurate calibration of butt and fillet type weld inspection.

For accurate calibration of butt and fillet type weld inspection.

Stainless Steel construction. Adjustable scale to compensate for point wear. For general linear measurements up to 60 mm or 2 inches.

Stainless Steel construction. Adjustable scale to compensate for point wear. For general linear measurements up to 60 mm or 2 inches.

The following measurements are possible either in inches or millimeters:

• Angle of preparation, 0-60º

• Excess weld metal (capping size)

• Depth of undercut

• Depth of pitting

• Fillet weld throat size

• Fillet weld length

• Misalignment (high-low)

G.A.L. Adjustable Fillet Weld Gauge is easy to use.

G.A.L. Adjustable Fillet Weld Gauge is easy to use.

This welding gauge can be used to :

1] To measure fillet welds place irregular curve edge flush to horizontal toe of weld so the Straight edge is in line with the horizontal member.

2] To measure weld throat thickness place the 45° angle end flush to the horizontal and vertical members. Loosen the thumb screw and slide the pointer until it touches the face of the weld.