1A] Permanent Magnetic Yoke - MAXIFLUX PMY

• PMY supplies longitudinal flux. Does not need external power for operation.

• PMY supplies longitudinal flux. Does not need external power for operation.

• Useful in testing finished parts during production, maintenance and repairs

• Highly flexible with articulating arms and rotating poles.

• Economical and Light weight- weighs only 2.00 Kgs.

• Highly concentrated magnetic flux. Meets ASTM specifications in load carrying capacity.

• Safe for use in explosive environments such as Refineries, Petrochemical complexes, Offshore platforms, Mines etc

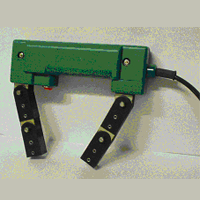

1B] MAXIFLUX ELECTROMAGNETIC YOKES

• The Yokes have articulated legs and flexible poles to fit on odd shape object.

• All circuitry is built in the handle for easy operation. No separate power supply.

• Yoke can be directly plugged in the mains 230Volts supply.

• Yokes working on 110 Volts AC or 48 V / 12 V DC supply also available.

• Duty cycle: Yokes are designed for 2 minutes on and 2 minutes off duty cycle.

• Yokes available with Battery operated power supply & built in charging system.

• All yokes weigh between 2.8 Kgs and 3.25 Kgs.

• Magnetic flux output meets and exceeds ASTM/ASME/BS/MIL specifications.

A] Maxiflux Yoke : MEY- 1

Model : MEY – 1

Model : MEY – 1

Magnetising Flux : AC

Input Power : 110 /230 V

Weight : 2.800 Kgs.

B] Maxiflux Yoke : MEY- 2

Model : MEY – 2

Model : MEY – 2

Magnetising Flux : AC / HW DC

Input Power : 110 /230 V

Weight : 3.500 Kgs

C] Maxiflux Yoke : MEY- 3

Model : MEY – 3

Model : MEY – 3

Magnetising Flux : AC / HW DC / FW DC

Input Power : 110 /230 V

Weight : 2.800 Kgs.

D] Maxiflux Yoke : MEY- 4

Model : MEY – 4

Model : MEY – 4

Magnetising Flux : DC

Input Power : 12and 42 Volts. ( 110 / 230 V - for Battery charging ).

Weight : 2.800 Kgs.

E] Maxiflux Yoke : MEY- 5

Maxiflux Coil Type Crack Detectors creates longitudinal flux in the test piece. The test piece is held inside the coil and can be moved in any direction to check for defect in all direction. Useful for finished parts where current can not be passed through the part. Most suitable for small size forgings, investment casting and finished parts.

Maxiflux Coil Type Crack Detectors creates longitudinal flux in the test piece. The test piece is held inside the coil and can be moved in any direction to check for defect in all direction. Useful for finished parts where current can not be passed through the part. Most suitable for small size forgings, investment casting and finished parts.

Operation : 10/ 230 volts or Battery operated Power supply.

Maxiflux Portable type crack detectors are light weight and highly versatile equipment. Available in both AC / HWDC flux, they are rugged work horses and designed for long trouble free service. They have advance electronic circuitry, simplicity in operation and less maintenance. Supplied with Pair of Magnetising cables and contact prods.

Maxiflux Portable type crack detectors are light weight and highly versatile equipment. Available in both AC / HWDC flux, they are rugged work horses and designed for long trouble free service. They have advance electronic circuitry, simplicity in operation and less maintenance. Supplied with Pair of Magnetising cables and contact prods.

Models Available : AD1000P/ AD1200P/ AD1500P/ AD2000P

Current Output : 1000 /1200 / 1500 / 2000 AC / HWDC

Power Input : 230 Volts, 50 Hz, 1 Phase

Maxiflux Mobile type crack detector works on 415 Volts, 50 Hz, 3 Phase supply. The equipment is provided with electronic SCR current control for current setting according to job requirement, circuit breakers and thermostats helps in avoiding overload and overheating.

Maxiflux Mobile type crack detector works on 415 Volts, 50 Hz, 3 Phase supply. The equipment is provided with electronic SCR current control for current setting according to job requirement, circuit breakers and thermostats helps in avoiding overload and overheating.

All models of Mobile type machines are provided with ports for connecting inspection lamps for black light units for ease in operation.

Models available in Mobile type crack detector are as :

Models Available : AD2000M/AD3000M/AD4000M/AD5000M

Current Output : 2000 / 3000 / 4000 / 5000 AC / HWDC

Power Input : 415 Volts, 50 Hz, 3 Phase

Maxiflux Stationary type crack detector works on 415 Volts, 50 Hz, 3 Phase supply. The equipment is provided with pneumatically operated head stock and crank operated tail stock for easy and fast clamping of test objects.

The test tray is made up of stainless steel fitted with circulating pump for spraying magnetic Particles. It is provided with collapsible hood for creating dark room and black light system for fluorescent particle testing.

Models available in Stationary type crack detectors:

Models Available : AD2000S/AD3000S

Current Output : 2000 / 3000 AC / HWDC

Power Input : 415 Volts, 50 Hz, 3 Phase