Our Products

- Safety Interlocks

- Liquid Rotor Resistance Starters (LRS)

- Liquid Rotor Resistance Regulator (LRR)

- Vapromatic Liquid Resistance starter

- Grid Rotor Resistance Speed Regulator (GRR)

- Buffer Resistance Panel

- Electric Control panel

- Control and Relay Panels

- Auto Transformer Starter (ATS)

- Neutral Grounding Resistors (NGR)

Contact Us

Enterprising Engineers

Mr. K.G. Bansal ( Managing Director )Mr. Nitin Bansal ( C.E.O.)

Mrs. Aparna Bansal ( Managing Partner )

(An ISO 9001:2008 Certified Company)

Plot No. 46 & 47, Sector-A,

Industrial Area, Govindpura,

Bhopal (MP)-462 023 (India)

Telefax : +91 755 2602964 / 2586684,

Office Mobile : +91 930 3196 591

E-mail : salesenquiry.ee@gmail.com ,

Website : www.enterprisingengineers.com

Safety Interlocks

We are a leading manufacturer of high quality Safety Interlocks that comes with fail proof safety to assure consecutive operation of one or more equipment. We have designed our Safety Interlocks to solve the various challenging needs of this diversified market.

Our highly skilled and qualified team of engineers has designed these devices with precision to provide our customers with the highest standard of International quality. With their years of experience we have been able to produce such hi-tech devices. We have also been able to customize our Safety Interlocks as per our customer’s needs and requirements. Thus we provide our customers with the complete solution devices.

Our vast range of Safety Interlocks comes with the following amazing features:

1. User Friendly Smooth Operation Device

2. Precise and Positive Interlocking

3. Visible Interlocked Condition in Casual Inspection

4. Assured Appropriate Sequence

5. Undefeatable Capability

6. Robust Construction

Key Exchange Box

A consists number of basic units type DL locks fixed to a steel box. The box houses a mechanism arranged such that certain keys are wrapped when others are removed its simplest form a control key is trapped until all other keys have been returned to their respective exchange box locks and turned to their trapped positions. The control key can then be removed, wrapping all other keys.

A consists number of basic units type DL locks fixed to a steel box. The box houses a mechanism arranged such that certain keys are wrapped when others are removed its simplest form a control key is trapped until all other keys have been returned to their respective exchange box locks and turned to their trapped positions. The control key can then be removed, wrapping all other keys.

Number of such key-exchange boxes can be kept in sheet steel door enclosure box. The design of this box has been tested at CPRI Bangalore and it ensures IP 55 protection.

Door Lock

Door Lock Type DT1 Or DT2

This interlock consists of two separate parts. One part is the basic interlock fixed on a Brass/Aluminum Body housing the mechanism. Another part is a sliding Bolt. When the sliding bolt is inserted in the main body and key is removed, the sliding bolt will remain trapped in the main body. To release the sliding bolt key should be inserted in the lock. This will release the bolt & trap the key.

Door Lock Type DT1 Or DT2

This interlock consists of two separate parts. One part is the basic interlock fixed on a Brass/Aluminum Body housing the mechanism. Another part is a sliding Bolt. When the sliding bolt is inserted in the main body and key is removed, the sliding bolt will remain trapped in the main body. To release the sliding bolt key should be inserted in the lock. This will release the bolt & trap the key.

Mechanical Interlock Type DL

This is the basic unit of our interlocking system. These locks consist of a mechanism housed within a brass body. A shaft of round or square cross section is projected from the rear of Lock-body. The lock is operated by inserting and rotating a special key in the lock. Standard Lock with 90°, 65°, or 45°, clockwise or Anticlockwise rotation can be supplied. In these, key is free only in one position. In another position it is trapped in the lock.

This is the basic unit of our interlocking system. These locks consist of a mechanism housed within a brass body. A shaft of round or square cross section is projected from the rear of Lock-body. The lock is operated by inserting and rotating a special key in the lock. Standard Lock with 90°, 65°, or 45°, clockwise or Anticlockwise rotation can be supplied. In these, key is free only in one position. In another position it is trapped in the lock.

The lock of one particular combination can be operated by the key of that combination only. The locks can be provided with spring loaded caps which will prevent ingrees of dust when key is out. Key can also be fitted with rubber caps to prevent entering of dust when key is trapped inside the lock.

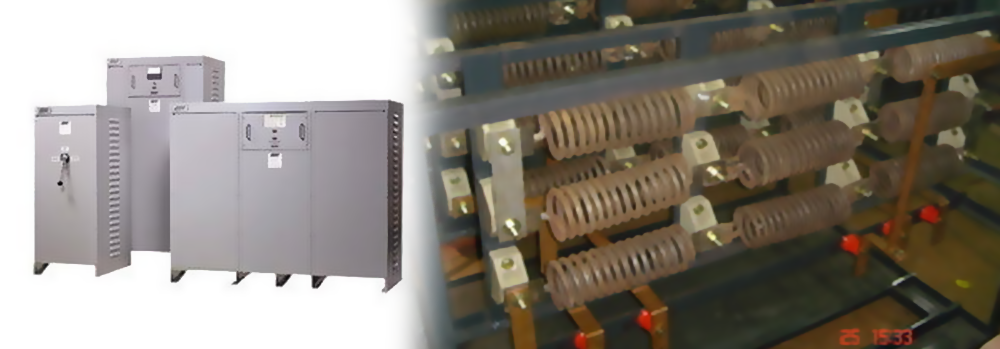

Liquid Rotor Resistance Starters (LRS)

These are used for inserting external resistance in the rotor -circuit of slip ring induction motor at the starting to reduce starting - current and increase starting - torque. used in various industries and installations like : cement plants, rolling mills , pumping plants, sugar mills, paper plants. we manufacture & supply liquid rotor resistances with both motor operated or manually operated mechanism. these give step - less cutting of resistance and are economical in comparison to wire wound or grid -resistances. we also manufacture stator - rotor panels.

Liquid External Resistance Starter

These are used for inserting external resistance in the rotor - circuit of slip ring induction motor at the starting to reduce starting - current and increase starting - torque. used in various industries and installations like : cement plants, rolling mills , pumping plants, sugar mills, paper plants.

We manufacture & supply liquid rotor resistances with both motor operated or manually operated mechanism. these give step - less cutting of resistance and are economical in comparison to wire wound or grid -resistances. we also manufacture stator- rotor panels.

These are used for inserting external resistance in the rotor - circuit of slip ring induction motor at the starting to reduce starting - current and increase starting - torque. used in various industries and installations like : cement plants, rolling mills , pumping plants, sugar mills, paper plants.

We manufacture & supply liquid rotor resistances with both motor operated or manually operated mechanism. these give step - less cutting of resistance and are economical in comparison to wire wound or grid -resistances. we also manufacture stator- rotor panels.

Liquid Rotor Resistance Regulator (LRR)

We are one of the most trusted names in electrical industry for designing & manufacturing of Grid Rotor Resistance Speed Regulator