Our Products

- Safety Interlocks

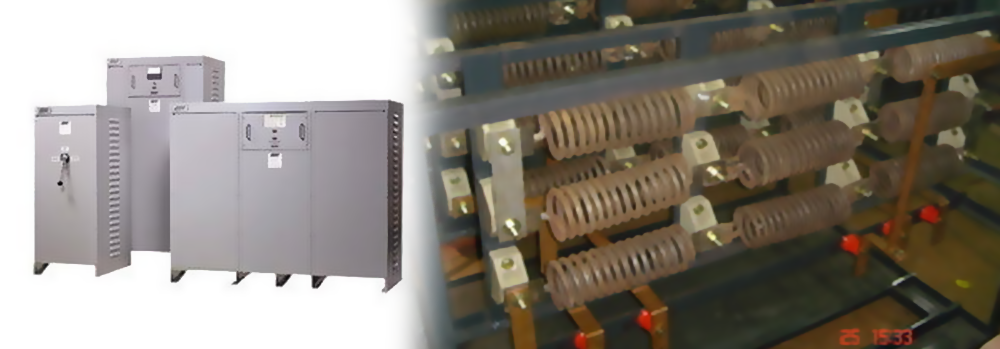

- Liquid Rotor Resistance Starters (LRS)

- Liquid Rotor Resistance Regulator (LRR)

- Vapromatic Liquid Resistance starter

- Grid Rotor Resistance Speed Regulator (GRR)

- Buffer Resistance Panel

- Electric Control panel

- Control and Relay Panels

- Auto Transformer Starter (ATS)

- Neutral Grounding Resistors (NGR)

Contact Us

Enterprising Engineers

Mr. K.G. Bansal ( Managing Director )Mr. Nitin Bansal ( C.E.O.)

Mrs. Aparna Bansal ( Managing Partner )

(An ISO 9001:2008 Certified Company)

Plot No. 46 & 47, Sector-A,

Industrial Area, Govindpura,

Bhopal (MP)-462 023 (India)

Telefax : +91 755 2602964 / 2586684,

Office Mobile : +91 930 3196 591

E-mail : salesenquiry.ee@gmail.com ,

Website : www.enterprisingengineers.com

About Us

Enterprising Engineers was established in 1972 by a team of qualified, experienced and enthusiastic engineers. With continued and dedicated efforts, Enterprising Engineers has now over 25 years of experience in designing and manufacturing MCC, PCC, electrical panels, stator rotor starters, marshalling boxes, switch boards etc.

What started with a humble dream has today transformed into a highly successful and trusted name in the electrical industry. With our constant commitment and focus we are constantly setting new standards of quality, safety and performance.

Our biggest asset is our highly skilled and experienced team that works closely with our clients to understand their specific requirement and accordingly manufacture products exceeding their expectation level. We have an in house competent team of engineers that design the products and processes and same vision is than translated into highly efficient products by our expert technical team.

The end result is a range of high quality products that include electrical panels for MCCs, PCCs & Switch Board, M. Box & Customer specific Panels like Control Desks, Instrument Panel, Starter Panels, mechanical interlock systems, key exchange boxes etc that meets all the global regulation and safety parameters.

Company Profile

Basic Information

- Business Type :

- Industry :

- Registered Address :

- Manufacturer

- Electrical equipments

- Plot No 46 and 47, Sector-A, Industrial Area, Govindpura, Bhopal - 462 023 Madhya Pradesh

Ownership & Capital

- Year of Establishment :

- Ownership Type :

- Proprietor Name :

- 1972

- Partnership

- Mr. Krishnagopal Bansal

Trade & Market

- Annual Turnover :

- 2010-11 US$ 1-10 Million (or Rs. 4-40 Crore Approx.)

Infrastructure

- Location Type

- Building Infrastructure

- Size of Premises

- Industrial

- Permanent

- 40,000 square feet

Team & Staff

- Total Number of Employees :

- 51 to 100 People

Company USP

- Quality Measures/Testing Facilities :

- Yes

Statutory Profile

- Banker

- PAN No.

- TAN No.

- EPF No.

- ESI No.

- Registration Authority

- Registration No.

- Central Sales tax No.

- Value Added Tax Registration No.

- Service Tax Registration No.

- Excise Registration No.

- SSI No.

- State Bank of India

- AAAFE8864C

- BPLE00027G

- MP/C053

- 18/7017/67

- Registrar of Firms, Bhopal

- Nil

- 1323 C

- 23143600092 V

- AAAFE8864CST001

- AAAFE8864CXM001

- SSI/MP/BPL/AGE/704/7

Packaging/Payment and Shipment Details

- Payment Mode

- Cash, Cheque

Certification & Membership

- Certification Name:

- Certification Type:

- International Organization for Standardization

- ISO 9001-2000

1. Salient Features Design & Constructional

• Control Panels are designed by a team of experienced engineers to meet customer's requirements & applications and are manufactured by expert technicians. Scores of these panels supplied in the past 25 years, are giving very satisfactory performance at various industries in the country.

• The Base Channel of Panels are of 75x40x5 mm size welded with the main structure.

• The complete wiring is done with adequate size of Copper flexibles duly thimbled, ferruled and sleeved. Minimum size used for Control is

1.5 sqmm copper and for power 4 sq mm copper.

• Openable gland plates fabricated out of 14 SWG M.S. sheet are provided.

• The panel is suitable for supply voltage 415/440 V, 3 phase, 4 wire system and ready for external wire/cable connections.

• The Panels have separate Cable/Busbar chambers duly partitioned with removable covers.

• No access to live parts inside the panel is possible to ensure personnel safety & avoid accidents.

• The Busbar supports are of DMC/SMC cast insulators with anti-tracking treatment.

• There is a separate cable support to avoid load on the thimble of cables as well as on the links.

• Each and every Switch/Starter has separate bus link or wired upto terminal block.

• Minimum operation height of components is 200 mm from ground level for ease of maintenance.

All the shipping sections, joints and doors are provided with effective gaskets.

CRCA sheet steel is used for LT Panels. All load

bearing members, doors and compoments plates are

fabricated from 2 mm thick sheets. Partitions and

other non-load bearing members are fabricated out

of 1.6 mm thick M.S. sheet.

The degree of protection of the Panel is IP-54 as

perlS-2147.

The Panels are treated with Chemicals for Derusting and Phosphating prior to 2 coats of zinc chromate base red oxide primer and finally two coats of paint to shade No. 631 of IS:5 or as per customer specification.

Quick-openable metallic Door Locks are provided for each and every hinged door.

All busbars are of Electrolytic Aluminium, insulated with PVC Heat Shrinkable coloured sleeves suitable for 40 kA fault level for one second.

A separate Gl earth busbar of adequate size is run

all along the length of entire panel.

The following Tests are carried out on each panel:

a. Continuity Test as per approved schematic and wiring diagram.

b. Insulation Test by 1000 V DC Megger.

c. High Voltage Insulation Breakdown test with 2.5 kV HV Test Kit.

d. Operational/Functional Tests as per approved Schematic Diagram and customer specification. Relays and Measuring Instruments are tested with Secondary Injection Kit.

Quality Control & Tests

We have sophisticated Quality Control Department equipped with modern testing facility and backed up by qualified and experienced persons to ensure better quality products. We use only highest-grade raw material sourced from reliable vendors. Similarly all components used are of original make procured through authorized dealers or directly from the manufacturers. Each component is inspected and tested by Q.C. department prior to use. Further stage inspections are carried out to ensure defect free product. And before final dispatch, rigorous testing of the panel is done to ensure adherence to specifications and avoid problems at site.

Quality Procedures For Welding

Welding is the only activity in our workshop where inspection at a later stage will not reveal its capabilities.

Quality procedure adopted for welding activity is:

Most cases involve 3mm to 5mm thick. Mild Steel cold rolled and hot rolled. These are cut and bent in required shapes and are but welded lap welded to other sheet components, base frames support members like Channels or Angles to produce Cubicles, Boxes, Tanks etc. Member to be welded are prepared by cleaning along the joint and then tack welding to retain them in position. These are then continuously welding to produce a sound blowhole proof weld seam electrodes used are 2.5mm to 3mm Dia with rutile coating. These are stored in dry enclosure and taken out when needed for actual welding.

Our Product Portfolio

Leveraging our state of the art manufacturing unit and experienced team, we offer unmatched designing and manufacturing support to our valued clients for all kind of electrical requirements.

Products manufactured by Enterprising Engineers are:

Electrical Panels,

Mechanical Interlock Systems,

Liquid Rotor Resistance/Starters and Controllers,

, Motor operated or Manual Mechanism., Key Exchange Boxes to ensure sequential operations of two or more interdependent functioning of Electrical & Mechanical Equipments. for MCCs, PCCs & Switch Board, M. Box & Customer specific Panels like Control Desks, Instrument Panel, Starter Panels.

Our entire range of products adheres to the international quality parameters and offers superior performance even at the most challenging work situations.

Material Used

We use only highest grade of raw material sourced from our reliable vendors. We follow stringent quality checks on our procured raw material to ensure highly efficient end products.

The main categories of raw material used are:

Mild Steel

Bulk of material used is Mild Steel in form of sheets, Flats, Angles & Channels. These are procured from the market and are of well established quality

Aluminium, Copper & Wiring Cables

These are used for Bus Bars & connection to Electrical Components. These are procured from reputed manufacturers.

Electrical Components

These are the main functioning and controlling components in our products. These are procured from well-established manufacturers like S&S, L&T, Siemens, Telemecanique, BCH, Elmex etc.

Engineering & Design

Safety Interlocks

Our main documents are General Arrangement Drawings, Assembly Drawings Schematic and Wiring Diagram. These are generated after careful & thorough study of customer specification and discussion. The customer duly approves both the documents before production is started. These documents are self-contained & provide complete information for materials, manufacturing & testing.

Production Facilities

The Production facilities at our works arc as follows:-

• Fabrication Shop

• Machine Shop

• Painting Shop

• Assembly and Wiring Shop

• Testing Section

Above facilities are adequate for the manufacture of Pressed & Machined Components. Fabricated Assemblies etc., which are needed for manufacture of Switchgear/ Control Gear Equipments, Control and Relay Panels. Power Control Centres. Mechanical Interlocks and Motor Starters.

A Packing & Despatch section takes care of safe packing and prompt despatch of manufactured products to customers.

• Fabrication Shop :-

Power Shearing Machine Portable Shearing Machine Power Press Brake Power Presses Hand Presses Power Hacksaw Portable Hacksaw Nibblinig Machine

Compressor Arc Welding Set Spot Welding Machine Welding Generator Portable Electrical Blower Electric Oven

Chain Pulley Block (2 Tonnes )

Welding Fixtures. Sand Disc Grinder

Hand Grinder

Machine Shop :-

Lathe Machine Special Purpose Lathe Shaping Machine Universal Milling Machine Radial Drilling Machine Templates

Bench Grinders Bench / Buff Grinder Portable Drilling Machine Double Column Drilling Machine Drill Jigs

Measuring Instruments for Machine Shop:-

Surface Plates Straight Edges

Micrometers Vernier Calipers

Height Gauge Go-Not-Go Gauges Depth Gauge

• Painting Shop:-

* Panels are fabricated by using, as far as possible, Cold-Rolled sheet steel. After fabrication, the entire sheet metal work undergoes Mechanical / Chemical pretreatment and painting.

* Seven Tank Process has been installed to derust, degrease & to Phosphatise the Sheet Steel Fabricated Panels.

* Heavy M.S. fabricated Assemblies are Shot-Blasted to remove rust and grease before painting.

* Two coats of Red Oxide / Zinc Rich Primer Paint and Two coats of Synthetic Enamel Paint are applied.

• Hardware used for assembly are Zinc Plated & Yellow passivated. (5-10 Microns)

• Assembly & Wiring Shop:-

Experienced filters and skilled Wireman with adequate tools & tackles carryout assembly and wiring work of various products as per relevant standards

• Testing Facilities:-

Need for proper testing facilities for any electrical product cannot be underestimated. Swichgear / Controlgear products are Control - cum - Protection equipment, hence providing the designed characteristics and verifying the same by testing are all the more essential. The following tests are conducted at our works-Testing & Inspection of all incoming materials.

Routine Tests such as Continuity Test, Meggaring . High Voltage Test and Operational Tests arc conducted on the manufactured assemblies and products before despatch.

Type Testing of products arc carried out in any reputed laboratory as and when required.

Our make Motor Control Centres and Distribution Boards have been Type -tested for Short Circuit withstand level of 50KA for 1 Sec, to confirm to IS 823 (Part 2).

Our Control Panels have been Type - tested for Dust and Water Proof feature as per protection clause IP-55 of IS:2147.

Heat run test upto 3000 Amps .can be carried out in - house by us to confirm to IS 8623 (Part I).

Customer Inspection & Witness

Wherever required customer's representative carries out their own quality checks at our works & approves for dispatch. M/s BHEL, NTPC, PGCL, LLYODES, RITES are our regular customer's who have also witnessed type Tests carried-out at reputed Labs of C.P.R.I.

Similarly for high level of customer satisfaction, any complaints received from Site / Customer are investigated & analyzed. Upon successful identification of non -conformity and source of non-conformity, preventative action, planning for control and implementation to eliminate the same are ensured.

Our Team

The credit to our phenomenon success goes to our highly experienced & committed team. Our expert team works closely with customers to understand their specific needs and accordingly customize product design and manufacturing to ensure maximum efficiency.

Our team is a mix of following skilled professionals:

Product Designers

Engineers

Quality Experts

R&D professionals

Technicians

Marketing Experts

Our Customers

We cater to requirements of various type of industries and have supplied our products to

* Electric Power Generation Stations

* Electric Power Sub- Stations

* Engineering Industries

* Cement Industries Chemical Industries

* Paper Industries

* Spinning Mills

* Water Pumping Stations

* Railways

* Coal Fields

* Electric Equipment Manufactures

* Steel Mills

SOME OF OUR IMPORTANT CUSTOMERS

We have supplied our products to -

* Bharat Heavy Electricals Limited (Bhopal, Banglalore & Ranipet. Jhansi Units)

* National Thermal Power Corporation Power Grid Corporation of India Limited

* India Railways (Central & Western)

* Crompton Greaves Limited

* Tata Chemicals Limited

* Associated Cement Companies

* J.K.White Cement

* Birla Diamonds Cements

* Jaypee Rewa Cements

* Modi Cement

* SAIL (Rourkela & Meghputra)

* Indus Steel

* KAP Steel

* Remimetal Industries

* NGEF Bangalore

* Essar Gujarat ( Mumbai & Vizag)

* ALSTOM Naini (earlier GEC)

* Kirlosker Electric

* Fertilizer Corporation of India Limited

* Larson & Tubro

* Asea Brown Boveri

* Mysore Electrical Industries

* Ordinance factory (VFJ )

Product range

* Electrical control panels

* Starters and controllers for large A/C motors

Our Products