Assembly

We have Fixed, as well as Flexible Assembly lines at our plant enabling us to cater to customers with requirements of high volumes as well as high variants. The lines are scientifcally designed to yield maximum productivity with zero defects using techniques of Line Balancing and Lean Management.

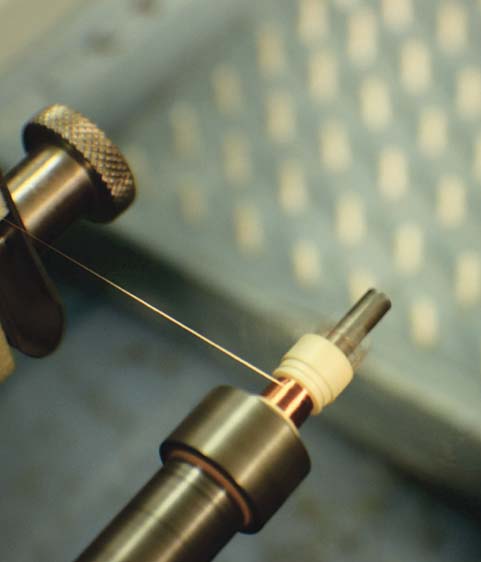

WINDING

We have automatic programmable high speed winding machines in our assembly shop, wherein we wind wires as thin as 60 microns (0.06 mm).

These windings are used for our electro-magnetic products like relays, solenoids and pick up assemblies. Our assembly processes involve electronic sub-assemblies and subsequent potting using epoxies and resins. The potting is performed to protect sensitive electronic components from impact, resistance to shock, vibration, loose wires and for the exclusion of water

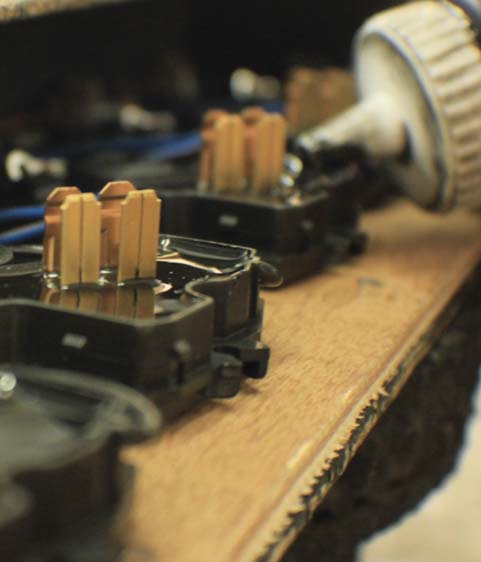

POTTING

Our assembly processes involve electronic sub-assemblies and subsequent potting using epoxies and resins.

The potting is performed to protect sensitive electronic components from impact, resistance to shock, vibration, loose wires and for the exclusion of water, moisture, or corrosive agents.

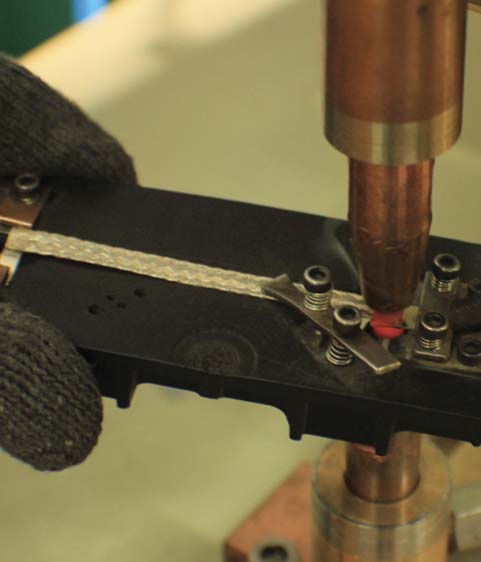

SPOT WELDING

Spot welding is a type of electric resistance welding used to weld various sheet metal products.

We incorporate precision spot welding processes, riveting, flarings, caulking, flaring and bending operations to join 2 metals or metals to plastic.

Different sheet thicknesses of various metals are involved in these operations.

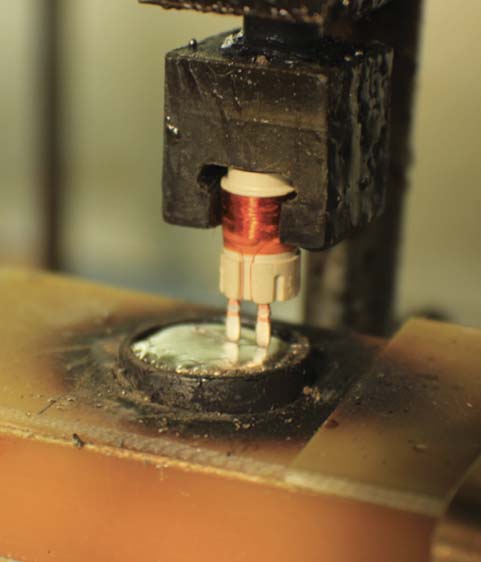

SOLDERING

Other processes in assembly include splicing, crimping and soldering to produce wire harnesses and pig tails for switches.

We do different kinds of soldering which include hard soldering, soft soldering and lead free soldering.

Besides the above, we also do cementing for resistors and Pad and inkjet printing for batch numbering of products and control panels.