Products

⇓ Ultrasonic Metal Welder

Principle : ultrasonic metal welder is based on principle of ultrasonic vibrations.

Principle : ultrasonic metal welder is based on principle of ultrasonic vibrations.

2 metal parts are held between Ultrasonic vibrating tool horn & knurled fixture. At a time pressure is provided vertically to the vibrations. Due to this, parts ate scrubbed against each other oxide layer is being removed & two parts get joined.

So Welding is being done without losing properties of material & without adding any properties

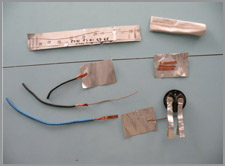

Ultrasonic welding is cold welding process. It is being applied to metals such as copper, brass, aluminium, tin, silver, gold, platinum. Ultrasonic metal welding has used for various application in industries for electrical joints, contacts, soldering, solar panel welding compoite pipes making from strips.

Iron caste heavy base

Iron caste heavy base