Key Machinery : Foundry

- Cupola Divided Blast Furnaces

- Induction Melting Furnace

- Holding Furnace

- Spectrometer

- Various capacity Sand Mullers

- Sand Mixers

- Air Compressors

- Pneumatic Rammers

- Pneumatic Chippers

- Hand Grinders

- 7 Nos. EOT Cranes

- Sand Sieve

- Loam Sand Mixer

- Sand Drier

- Welding rectifiers / MIG setups

- Core Drying Ovens

- Laddles For Liquid Metal

- Cupola Charging Weighing Scale

- Crane Weighing System

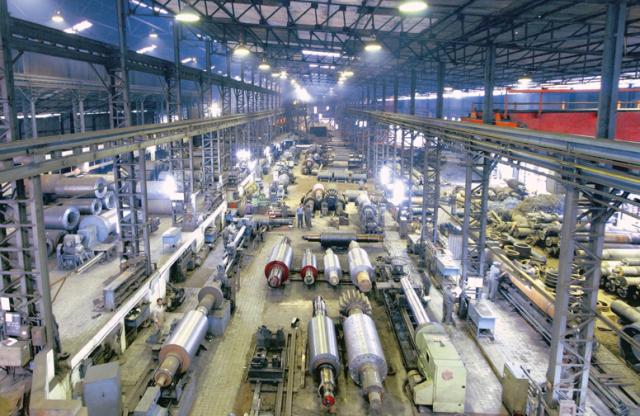

Key Machinery : Machine shop

- Heavy Duty Lathes

- Bombay Lathe

- Flange Lathe

- Plano Millers

- Shaping Machine

- Bandsaw Machine

- Shimoga Lathes

- Drilling Machines

- SPM For Grooving Of Sugar Mill Rollers (CNC)

- Lathe For Rings Machining

- Special Purpose Lathes

- Special Purpose Horizontal Boring Machines

- EOT Cranes

Quality Control Laboratory Equipments

- Strohlein Apparatus

- Hot Plate

- Digital Pyrometers

- Heavy Duty Drill

- Optical Pyrometer

- Electronic Weighing Machine

- Standard Weighing Scale

- Muffle Furnace (For Silicon Determination)

- Sand Testing Equipments

- Distilled Water Generator

Man Power Detail

| Description | Nos. |

| Director | 8 |

| Managers | 11 |

| Officers | 28 |

| Others | 21 |

| Permanent Labor | 141 |

| Contractual Labor | 125 |

| Contractual Labor (seasonal) | 260 |

Strengths

- 35 years of experience in Reshelling business.

- Highest casting capacity of 10,000 tons p.a. for sugar rollers.

- SBR has almost 100% New Rollers business of Indian Sugar Mill OEMs.

- 50% to 60% market share in reshelling of sugar mill roller business. SBR produces 1500 rollers p.a.

- High technical expertise to manufacture any type of shell with maintaining perfect melting temperature & perfect chemical composition.

- Two patented rollers Kamal Rollers & SBR Alloy Roller shows excellent designing capabilities that has become the industry norm.

- Rollers manufactured are highly wear resistant providing better life span and high performance.

- Capable of precision “Shrink fitting”, a vital facility available in the industry.

- Strong Technical knowledge, Vast experience and Good knowledge of Indian market.

- Export orders from USA, UK, Australia, France, Sudan, Malaysia, Philippines, Indonesia, Venezuela, Pakistan, Kenya, etc.

- A separate machine-shop and stress relieving facility.

- Dedicated pattern making department for tailor made castings.

- Well equipped quality control setup and processes.

- Dedicated design team with highly qualified engineers.

- Excellent product quality with almost zero defect.

- SBR also manufactures other heavy castings such as pump and valve casting to utilize spare casting capacity in the off-season period.