Angleboard is manufactured with multiple layers of paperboard, laminated with glue and formed into a rigid right angle, providing exceptional strength for load stability and packaging protection. Angleboard is available in a variety of lengths, leg-sizes and thicknesses.

Angleboard is manufactured with multiple layers of paperboard, laminated with glue and formed into a rigid right angle, providing exceptional strength for load stability and packaging protection. Angleboard is available in a variety of lengths, leg-sizes and thicknesses.

LITEC Edgeprotectors are manufactured in a proprietary process with paper, LDPE and foil. The materials are bonded and laminated under controlled heat and pressure for diverse applications. Raw materials and water based inks used are environment friendly and recyclable. LITEC was developed to overcome problems associated with damp/wet conditions. As a result it is very effective in freezer/cold storage applications.

LITEC Edgeprotectors are manufactured in a proprietary process with paper, LDPE and foil. The materials are bonded and laminated under controlled heat and pressure for diverse applications. Raw materials and water based inks used are environment friendly and recyclable. LITEC was developed to overcome problems associated with damp/wet conditions. As a result it is very effective in freezer/cold storage applications.

ITW Reddi-Pac products are manufactured with laminated paperboard and help prevent product damages that can occur during shipping and handling. ITW Reddi-Pac is an excellent replacement for wooden crates that are shipped overseas – providing superior strength and protection for almost any application.

LITEC Edgeprotectors are manufactured in a proprietary process with paper, LDPE and foil. The materials are bonded and laminated under controlled heat and pressure for diverse applications. Raw materials and water based inks used are environment friendly and recyclable. LITEC was developed to overcome problems associated with damp/wet conditions. As a result it is very effective in freezer/cold storage applications.

LITEC Edgeprotectors are manufactured in a proprietary process with paper, LDPE and foil. The materials are bonded and laminated under controlled heat and pressure for diverse applications. Raw materials and water based inks used are environment friendly and recyclable. LITEC was developed to overcome problems associated with damp/wet conditions. As a result it is very effective in freezer/cold storage applications.

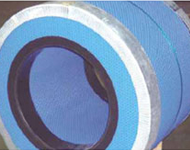

Protex is a close structured plastic material. Protex provides a cushion between the product and the outer face of the packaging and its superior mechanical performance provides effective coil or pack protection.

Protex is a close structured plastic material. Protex provides a cushion between the product and the outer face of the packaging and its superior mechanical performance provides effective coil or pack protection.

Protex is available in coil or sheet form and can be cut to the desired size with a hand knife. Its patented "T" pattern allows for easy cutting especially in a straight line.

Protexs unique T design gives maximum strength with minimum material. The T design enhances rigidity in both linear and width directions. It enables easy and secure over-lapping with excellent interlocking.

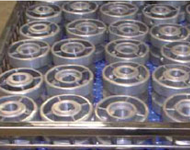

METWRAPP is manufactured from polypropylene. It has a two or three layer structure with either one or both the surfaces with plain sheet and a middle layer of bubbles that are thermoformed and welded on the plain sheet to form a homogeneous structure. Bubbles have a high contact area. This provides high compression resistance and also equal strength in all directions.

METWRAPP is manufactured from polypropylene. It has a two or three layer structure with either one or both the surfaces with plain sheet and a middle layer of bubbles that are thermoformed and welded on the plain sheet to form a homogeneous structure. Bubbles have a high contact area. This provides high compression resistance and also equal strength in all directions.

Specifications

Two layer bubble guard sheet is specially designed for top sheet and inner dia applications to take the shape of the product. Ensures product protection and aesthetic look of the pack.

Three layer bubble guard sheet is designed for side disc application. The stiffness and rigidity provides the necessary cushioning required.