HLS

HLS

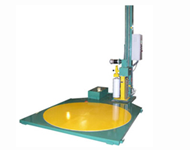

New generation sensor stretch wrapping machine with top platon optional for higher loads can be retrofitted in same column with capacity of approximately 30 pallets per hour.

HLS2000 semiautomatic sensor stretch wrapping machine with improved turn table design and safety features wraps approximately 30 pallets per hour.

HLS2000 semiautomatic sensor stretch wrapping machine with improved turn table design and safety features wraps approximately 30 pallets per hour.

FE-LP Stretch Wrapping Machines for pallet loads of random heights weighing up to 2000 kgs are available both in semi-automatic and automatic models. Custom designed machines are also available for different load sizes. These machines are fitted with photo eye sensing option to sense the height of the load automatically.

FE-LP Stretch Wrapping Machines for pallet loads of random heights weighing up to 2000 kgs are available both in semi-automatic and automatic models. Custom designed machines are also available for different load sizes. These machines are fitted with photo eye sensing option to sense the height of the load automatically.

FE-LP is also available in dual-turntable configuration for increased throughput capacity. Some of the typical applications include all export palletized cargo and bulk unitization.

Stretch wrap up to 30 loads per hour

Variable speed turntable for soft start

Automatic load height sensing

Internal speed controls for turntable and elevator

Modular components for easy replacement

ITW Signode offers semi-automatic carton wrappers with top platen and turn table for carton wrapping on all surfaces.

ITW Signode offers semi-automatic carton wrappers with top platen and turn table for carton wrapping on all surfaces.

Features

Machine can be used for carton wrapping on all surfaces

0-300% variable pre-stretch ensures minimum cost of consumables, while maintaining optimum load integrity

Independent film tension adjustment to enable wrapping of light cartons and delicate cartons with less tension and heavier cartons with more tension

Convenient operating height of 800 mm which will give less operator fatigue and more output

Logic control through PLC

Cobra-Lite Portable Stretch Wrapping Machine excellent for dispersed packaging, equipped with rotary arm and up/down carriage for complete product wrapping.

Cobra-Lite Portable Stretch Wrapping Machine excellent for dispersed packaging, equipped with rotary arm and up/down carriage for complete product wrapping.

COBRA III Semi automatic wrapping machine for pallet loads.

COBRA III Semi automatic wrapping machine for pallet loads.

COBRA III is ideal for wrapping palletized loads that unstable, very light or very heavy or odd-sized and of any shape and type of the product.

ITW Signodes Spider is an axial and radial stretch wrapping machine with a rotating film carriage and wrapping program.

ITW Signodes Spider is an axial and radial stretch wrapping machine with a rotating film carriage and wrapping program.

Axial Wrapping : Wraps the reel in the axial direction and also protects from dust and other foreign particles.

Radial Wrapping : Wraps the reel in the radial direction and provides cushioning effect for the reel during handling

Dual direction wrapping on the Spider results in substantial reduction in packaging time, improves productivity and reduce lower manpower cost.

Features and Advantages

High Level Powered Pre-stretch Mechanism

The heart of the machine is its powered prestretch film delivery, a system which elongates stretch film at a consistent rate prior to being wrapped around the load. This high level of prestretch saves you money by increasing the yield from every roll of film. It also provides for superior load retention because prestretched film is stronger and resists further stretching. The Accustretch I TM prestretch carriage uses patented technology to ensure consistent film output around the load. As the carriage rotates around the product/load, film payout is increased or decreased. The films wrapping tension (force-to-load) can be controlled. For light, fragile loads, film tension can adjust to as little as little as 1.3 kgs.

Adjustable, enclosed Photoeye for automatic load height sensing

Convenient Photoeye on-off switch

Specially textured prestretch rollers resist tackifier build up and provide years of consistent service

Accepts standard 20 film roll, 21 to 50 microns

VFD for controlling the rotation speed

Operator and product safety features

Automatic control and interlocks through PLC

The Cobra-XL incorporates many of the performance features of our Cobra models plus a modular design which makes it easy to expand the system as your needs change, the real beauty of Cobra-XL is its price. With our AccuWrap film bulk discount programme, you can own the platform model XL at a price lower than that of an equivalent imported system.

The Cobra-XL incorporates many of the performance features of our Cobra models plus a modular design which makes it easy to expand the system as your needs change, the real beauty of Cobra-XL is its price. With our AccuWrap film bulk discount programme, you can own the platform model XL at a price lower than that of an equivalent imported system.

Cobra-XL Features

Overhead spiral wrapping for maximum load stability

Available in 4 models: powered or gravity conveyor, platform, conveyor-ready

The CoilMasters axial, or through-the-eye, stretch wrapping system fully encapsulates coils of strip and wire products in a protective cocoon of film, providing protection from contaminants, moisture and surface damage.

The CoilMasters axial, or through-the-eye, stretch wrapping system fully encapsulates coils of strip and wire products in a protective cocoon of film, providing protection from contaminants, moisture and surface damage.

The CoilMaster packaging system represents a major advance in the packaging of steel and aluminium coils with the application of microchip technology and innovative engineering.

It is an automatically operated system that uses a heavy gauge stretch film for the wrapping of coils. The concept used is for a specifically shaped track to carry a film dispensing shuttle through the eye of the coil, while the coil is slowly rotated on its axis on a set of blocker rollers. The complete body of the coil is, therefore sealed by a cocoon of stretch film. Ancillary protective packaging can be incorporated into the system.

The Octopus CTS is fully automatic wrapping machine incorporating the latest technology and the famous Octopus ring type method. With integrated top sheet device in Octopus CTS, you can make real splash proof wrapping. Octopus CTS offers more cost-effective solution than rotating arm or rotating table machine, when top sheet is required.

The Octopus CTS is fully automatic wrapping machine incorporating the latest technology and the famous Octopus ring type method. With integrated top sheet device in Octopus CTS, you can make real splash proof wrapping. Octopus CTS offers more cost-effective solution than rotating arm or rotating table machine, when top sheet is required.

The wrapping film reel is suspended from a ring and it revolves around the pallet. The ring is raised and lowered according to the wrapping program. The pallet remains stationary, which makes the wrapping of unstable and lightweight products considerably easier.

The Octopus steel version is fully automatic wrapping machine incorporating the latest technology and the famous Octopus ring type method. The wrapping film reel is suspended from a ring and it revolves around the pallet. The ring is raised and lowered according to the wrapping program.

The pallet remains stationary, which makes the wrapping of unstable and lightweight products considerably easier. There are no centrifugal forces to cause stress or strain on the load or on the equipment. As the ring can be accurately positioned in the vertical direction, wrapping can be started and finished at any height required.

The Octopus wraps down to 7 cm of the floor or top of the conveyor to ensure that the finished package is tight, strong and secure...

The Ringmaster horizontal stretch wrapping system is ideal for unitizing pipe, tubing, textile rolls, carpeting, lumber, molding, doors, siding and more. By fully encapsulating products in a web of film, the Ringmaster provides protection from scratches, dirt, dust and moisture. Semiautomatic and automatic models are available.

The Ringmaster horizontal stretch wrapping system is ideal for unitizing pipe, tubing, textile rolls, carpeting, lumber, molding, doors, siding and more. By fully encapsulating products in a web of film, the Ringmaster provides protection from scratches, dirt, dust and moisture. Semiautomatic and automatic models are available.