» Our Products

Changes in market patterns reflect changing perceptions in human preferences and lifestyle, whose transformation occurs at once unconsciously and by deliberate design. The present trend in food and drink packaging and presentation has underscored change as an unalienable part of our lives. For the best part of three decades Technopet has concentrated singularly on designing and configuring machinery to produce end products that can surpass even the best internationally.

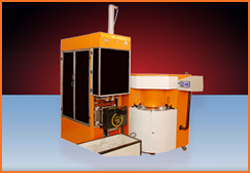

• Fully Automatic Machines

Top stretch Fully automatic machine with preform descrambler, sorter/ segregator, Oriantor, auto loader and bottle ejection system. Non oriented bottle out-put on belt conveyor. No manual interfacing being continuous process. In built process monitoring and control.

Top stretch Fully automatic machine with preform descrambler, sorter/ segregator, Oriantor, auto loader and bottle ejection system. Non oriented bottle out-put on belt conveyor. No manual interfacing being continuous process. In built process monitoring and control.

Our Range of Fully Automatic Machines:

• Auto-1800

• AUTO HOT FILL

• Auto Amber

• On LIne Pet Blowing Machine

On Line PET stretch blow-moulding machine for the production of bi-axially oriented high quality PET bottles at the lowest conversion cost. Gravity direction stretch with blowing in neck up position facilitate easy vertical bottle out put from mould cavity of machine. Direct transfer of blown bottles on the in-feed bay of filling station satisfy the ON-LINE requirement of filler without any mechanical gimmicks and air conveyor.

On Line PET stretch blow-moulding machine for the production of bi-axially oriented high quality PET bottles at the lowest conversion cost. Gravity direction stretch with blowing in neck up position facilitate easy vertical bottle out put from mould cavity of machine. Direct transfer of blown bottles on the in-feed bay of filling station satisfy the ON-LINE requirement of filler without any mechanical gimmicks and air conveyor.

Being compact machine is very convenient to install next to filling machine. Easy operation, simple controls and low profile maintenance by semi-skilled person are prime objective of machine design.

Our Range of ON Line PET Blowing Machines:

• TP OL 900

• TP OL 1800

• TP OL 2700

• TP OL HOT FILL

• TP OL Amber

• Partly Automatic Pet Blowing Machine

These machines are recently developed to meet the on line filling need of bottle to match the speed of 10 to 60 bpm. Low capital investment project with lowest conversion cost is capable of producing 12 to 72,000 bottles per day by using loose dimension tolerance local make preforms. Oriented bottle out-put on conveyor can directly feed the bottle to filling line. Preforms are manually put into the oven and transfer to loading system. Bottle ejection from mould and other operations are automatic.

These machines are recently developed to meet the on line filling need of bottle to match the speed of 10 to 60 bpm. Low capital investment project with lowest conversion cost is capable of producing 12 to 72,000 bottles per day by using loose dimension tolerance local make preforms. Oriented bottle out-put on conveyor can directly feed the bottle to filling line. Preforms are manually put into the oven and transfer to loading system. Bottle ejection from mould and other operations are automatic.

Our Range of Partly Automatic PET Blowing Machine:

• PAuto 600

• PAuto 1200

• PAuto 1800

• PAuto HOT FILL

• PAuto Amber

• Semi Automatic Pet Bottle And Jar Blowing Machine

These are lowest capital- low speed PET blowing machine with 2 and 4 cavity mould is operated by single and two operator resp. Cold/hot preform handling and bottle ejection from mould is manually operation, preferred by converter or smaller filling unit requires 12 to 25,000 bottles per day.

These are lowest capital- low speed PET blowing machine with 2 and 4 cavity mould is operated by single and two operator resp. Cold/hot preform handling and bottle ejection from mould is manually operation, preferred by converter or smaller filling unit requires 12 to 25,000 bottles per day.

Our Range of Semi Automatic PET bottle and jar blowing Machines:

• TPX 2x2x5

• TPS-20L

• Semi HOT FILL

• Semi Amber