Specialist in on-site, spindle taper grinding, for repair and restoration of precision

Less downtime saves money, fast, reliable services, precision results

UPSPL can offer unique services “On site taper grinding” for faulty taper bores of VMC/HMC spindles.

We can bring our spindle grinding equipment to your location and grind your spindle tapers back to specifications in place in the machine, to ensure greater concentricity to the bearings and thus minimum run out. Regrinding in place also eliminates the tear down required to remove the spindle and lessens the down time you would normally experience to save your money.

We can bring our spindle grinding equipment to your location and grind your spindle tapers back to specifications in place in the machine, to ensure greater concentricity to the bearings and thus minimum run out. Regrinding in place also eliminates the tear down required to remove the spindle and lessens the down time you would normally experience to save your money.

We use special precision grinding equipment, designed and built by us, for this purpose.

Our grinding machines feature a set up gage, which is indicated in to your machine’s spindle, setting the proper geometry for grinding the seat, on taper, regardless of the machines alignments.

This method eliminates the error of tolerance stacked up upon assembly and is the most accurate method of grinding the taper seat true to spindle rotation.

Spindle Taper Problems

Spindle Taper Problems

There are four major spindle taper problems with which all manufacturers need to be concerned.

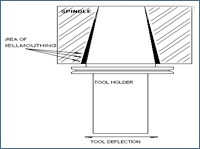

The first taper problem is bellmouthing. Bellmouthing takes place naturally as the spindle taper wears during continued use. It usually occurs at the large diameter of the taper, leaving contact only at the small diameter portion, which may account for fifty percent or even less of the total spindle taper contact area. This reduced contact leads to increased tool movement and greater tool runout.

Because bellmouthing happens very gradually over a long period of time, it often goes unnoticed. The drawing (figure 1) below shows the area of wear (or bellmouthing) on the spindle taper.

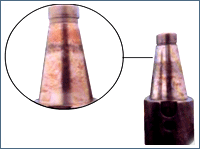

This lack of contact between the tool holder and the spindle will first begin to show on the machine spindle taper (and tool holder) as fretting. This is easily seen by the eyes of the operator as rust colored areas, or spots (Figure 2). The machine operator will begin to observe such symptoms as tool chatter on workpiece surfaces, carbide inserts chipping at the cutting edge and inconsistent bore sizes.

This lack of contact between the tool holder and the spindle will first begin to show on the machine spindle taper (and tool holder) as fretting. This is easily seen by the eyes of the operator as rust colored areas, or spots (Figure 2). The machine operator will begin to observe such symptoms as tool chatter on workpiece surfaces, carbide inserts chipping at the cutting edge and inconsistent bore sizes.

The second taper problem is machine malfunction or operator error.

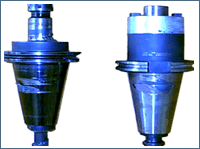

This can cause a tool holder to spin inside the spindle taper. This condition leads to a buildup of galled material, which completely eliminates contact of the tool with the taper surface. Although attempts to grind away the material buildup by hand can increase taper contact, the increase is usually not sufficient to achieve satisfactory work piece quality. Furthermore, such grinding can irreparably damage (Figure 3) an otherwise repairable spindle.

The third taper problem is weak tool retention. This problem can cause tool chatter, even though the spindle taper is acceptable. Unchecked, the condition inevitably leads to premature taper wear of the machine spindle and of the tool holder.

The third taper problem is weak tool retention. This problem can cause tool chatter, even though the spindle taper is acceptable. Unchecked, the condition inevitably leads to premature taper wear of the machine spindle and of the tool holder.

The fourth taper problem is the use of worn tool holders. Using worn tool holders in a new, rebuilt, or reground spindle will cause premature spindle taper wear, due to inefficient contact between the tool and the taper. Tool holder condition is as important as spindle condition.

In-Place Regrinding Process

Before the start of the in-place spindle taper regrinding process, amount of taper runout, extent of taper contact, taper gage line dimensioning, and drawbar clamping retention must first be determined.

Determine taper runout: A .00010" or .000050" dial test indicator reading is taken from the spindle taper surface. These readings are augmented using a precision test bar.

Determine taper contact: The amount of taper contact is determined using a precision taper gage with bluing. This procedure shows the extent of contact, as well as the points in the taper at which contact requires improvement.

Taper gage line dimensioning: The precision taper gage is also used to determine the gage line dimension.

Determine drawbar clamping retention: This reading can be acquired using a precision dynamometer that has been clamped into the spindle.

All measurements are documented and the spindle centerline is checked for purposes of grinding unit alignment.

Specially designed grinding equipment is put to use.

A series of fine tuning adjustments of the grinding unit (inside the spindle taper) are made.

Grinding continues until an acceptable level of taper contact has been achieved (usually no less than 90 percent contact and in most cases closer to 100 percent). At this point the spindle taper grinding process is complete.

All measurements documented prior to regrind are again preformed and documented.

After the results are reviewed by the customer and accepted, the grinding unit is disassembled from the machine.

The machine tool is now ready for set-up to once again run accurate precision parts.