You are here:

Products > Heat Shrink Sleeve > Power Cable Accessories > WRSFM(Heat Shrink Cable End Cap)

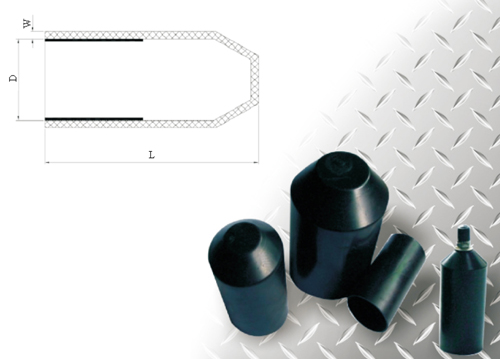

WRSFM(Heat Shrink Cable End Cap)

Description

Description

Used to seal cable ends during installation or storage, protecting cable ends against oxidation, ozone, UV, etc

Coated with hot-melt adhesive to ensure reliable seal of cable ends

Continuous operation temperature: -45? to 105?

Shrink temperature: start at 110?, and fully recovered at 130?

Shrink ratio: 2:1

Selection Table

| Product No. | D/mm | L/mm | W/mm | ||

| As supplied | After recovery | As supplied | After recovery | ||

| WRSFM-11/6 | =11 | =6 | =22 | 0.7±0.1 | =1.1 |

| WRSFM -16/8 | =16 | =8 | =70 | 1.2±0.1 | =2.2 |

| WRSFM -20/8 | =20 | =8 | =70 | 1.2±0.1 | =2.2 |

| WRSFM -25/11 | =25 | =11 | =80 | 1.2±0.1 | =2.3 |

| WRSFM -32/16 | =32 | =16 | =90 | 1.5±0.1 | =2.5 |

| WRSFM -50/26 | =50 | =26 | =115 | 1.5±0.1 | =2.8 |

| WRSFM -70/30 | =70 | =30 | =120 | 1.8±0.1 | =3.2 |

| WRSFM -100/46 | =100 | =46 | =140 | 1.8±0.1 | =3.5 |

| WRSFM -120/57 | =120 | =57 | =155 | 1.8±0.1 | =3.5 |

| WRSFM -140/60 | =140 | =60 | =180 | 2.0±0.1 | =4.0 |

| WRSFM -250/90 | =250 | =90 | =270 | 2.0±0.1 | =4.0 |

Remark:The end cap coated with hot-melt adhesivecomes in two forms: plane adhesive and spiral adhesive, which can meet different customer needs.

Technical Data

| Property | Test Method | Typical Performance |

| Operation Temperature | IEC 216 | -45? to 105? |

| Tensile Strength | ASTM-D-2671 | =12MPa |

| Elongation at Break | ASTM-D-2671 | =300% |

| Tensile Strength after Aging | ASTM-D-2671 | =10MPa (130?,168hrs) |

| Elongation at Break after Aging | ASTM-D-2671 | =230% (130?,168 hrs) |

| Dielectric Strength | IEC 60243 | =20kV/mm |

| Stress Cracking Resistance | ASTM-D-1693 | No cracking |

| Volume Resistivity | IEC 60093 | =1×1014O·cm |

| Fungus and Decay Resistance | ISO 846 | Pass |

| Longitudinal Shrinkage | ASTM-D-2671 | =10% |

| Eccentricity | ASTM-D-2671 | =30% |

| Water Absorption | ISO 62 | =0.5% |