You are here:

Products > Heat Shrink Sleeve > Power Cable Accessories > WRSXP (Heat Shrink Repair Sleeve)

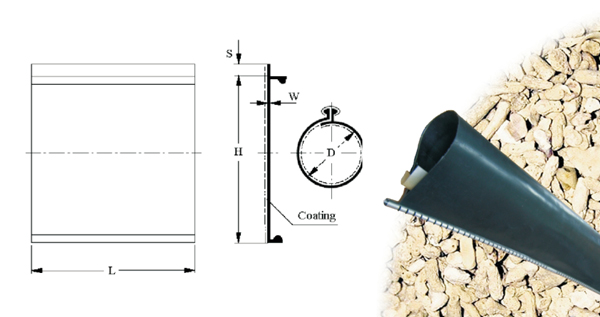

WRSXP (Heat Shrink Repair Sleeve)

Description

Description

Providing fast and permanent repair and sealing protection for power cables

High tensile strength, abrasion and corrosion resistance

Suitable for applications in cable joints and terminations

Continuous operation temperature: -45? to 105?

Shrink temperature: start at 100?, and fully recovered at 130?

Selection Table

| Product No. | Inner Diameter | After Recovered | Standard Length | |

| As Supplied(Min) /mm | After Recovered(Max) /mm | Wall Thickness(±10%)Nom. /mm | (mm) | |

| WRSXP-30/12 | 30 | 12 | 3.8 | 450-1000 |

| WRSXP-40/18 | 40 | 18 | 3.8 | 450-1000 |

| WRSXP-50/18 | 50 | 18 | 3.8 | 450-1000 |

| WRSXP-60(65)/22 | 60(65) | 22 | 3.8 | 450-1000 |

| WRSXP-80(85)/35 | 80(85) | 35 | 3.8 | 450-1000 |

| WRSXP-100/35 | 100 | 35 | 3.8 | 450-1000 |

| WRSXP-120/40 | 120 | 40 | 4.0 | 450-1000 |

| WRSXP-150(160)/50 | 150(160) | 50 | 4.0 | 450-1000 |

| WRSXP-170/55 | 170 | 55 | 3.8 | 450-1000 |

| WRSXP-195/70 | 195 | 70 | 2.0 | 450-1000 |

| WRSXP-170/55* | 170 | 55 | 3.8 | 400-600 |

| WRSXP-195/70* | 195 | 70 | 2.0 | 400-600 |

| WRSXP-240/90* | 240 | 90 | 2.0 | 400-600 |

| WRSXP-290/115* | 290 | 115 | 2.0 | 400-600 |

Remark: * means heat shrink repair sleeve without coated hot-melt adhesive.

Technical Data

| Property | Test Method | Typical Performance |

| Tensile Strength | ASTM-D-2671 | =17MPa |

| Elongation at Break | ASTM-D-2671 | =500% |

| Tensile Strength after Aging | ASTM-D-2671 | =14MPa (130?,168hrs) |

| Elongation at Break after Aging | ASTM-D-2671 | =400% (130?,168 hrs) |

| Dielectric Strength | IEC 60243 | =20 kV/mm |

| Volume Resistivity | IEC 60093 | =1014O·cm |

| Longitudinal Shrinkage | ASTM-D-2671 | =10% |

| Water Absorption | ISO 62 | =0.5% |

| Eccentricity | ASTM-D-2671 | =30% |