Deodorisation

Deodorisation is the final stage of refining to remove free fatty acids, odor and color pigments to produce bland oil with a good shelf life.

Brissun with an experience of a decade in the field of rice bran oil & all other oils deodorization has perfected the art of deodorization.

The deodorization process we follow is a mixture of packed column and tray type deodorization. Highly efficient and specially designed packing along with specially designed tray system gives oil maximum retention time and maximum surface area for evaporation.

PROCESS DESCRIPTION

» Deaeration

» Heating

» Stripping

» Deodorization

» Heat Recovery / Cooling

» Final Cooling

» Fatty Acid Recovery

» Polish Filtration

Bleached and dewaxed oil enters the dearation vessel after heating by phe, oil is sprayed in the vessel and air along with metal traces are removed /evaporated through vacuum. Oil after dearation enters regenerative heater which is under vacuum incoming oil is heated and final hot oil is cooled down, maximum heat recovery (80-85%) takes place.

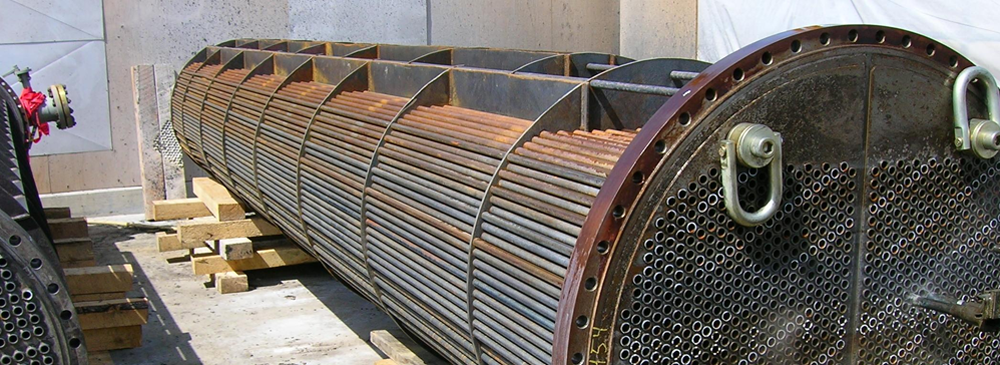

Partially heated oil is fed to vacuum heater, where oil is heated by thermic fluid or high pressure steam to 240°C – 250°C, FFA removal takes place during heating and the oil flows under gravity to distillation column equipped with high efficient structured packing which has very low pressure drop. Maximum number of distillation stages takes place by counter current flow of oil & vapors coming from bottom.

Oil after coming from packing is collected at bottom and fed to holding vessel equipped with number of trays, here thermal bleaching and deodorization takes place. Here all the bad odor and final traces of free fatty acids are removed.

After all the deodorization hot oil has to be cooled first in economizer and Then by cooler and phe to about 45°C and sent for storage.

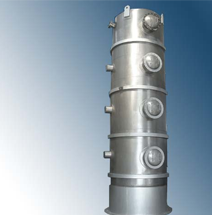

Free fatty acid vapors collected from deodorizer, heater and economizer are taken to scrubbing through central ducting and scrubbed in scrubbing column having a structured packing. Scrubbing is so designed that traces of fatty acid carryover in vacuum system and water is reduced to zero level.

ADVANTAGES OF OUR SYSTEM

» Maximum odor, flavor removal

» Maximum fatty acid removal (15-20%)

» Color reduction by thermal bleaching

» Keeping essential fatty acids intact in the oil

» Maximizing quantity of Tocopherol, Ariznol & other nutrients in final oil

» Low steam consumption

» Low electricity consumption

» Easy maintenance

» Low oil losses

» Low water consumption

» Highly efficient scrubbing of fatty acid (95% FFA concentration)

» Minimal carry over of fatty acids in water pool

» High heat recovery through regeneration