Dewaxing

Dewaxing process consists in removing glycerides and waxes from oil, by The oil to required temperature, giving proper retention time for wax crystals to grow And the filtered with the aid of plate & frame filters. For different oil’s temperature program is different and different process parameters are followed.

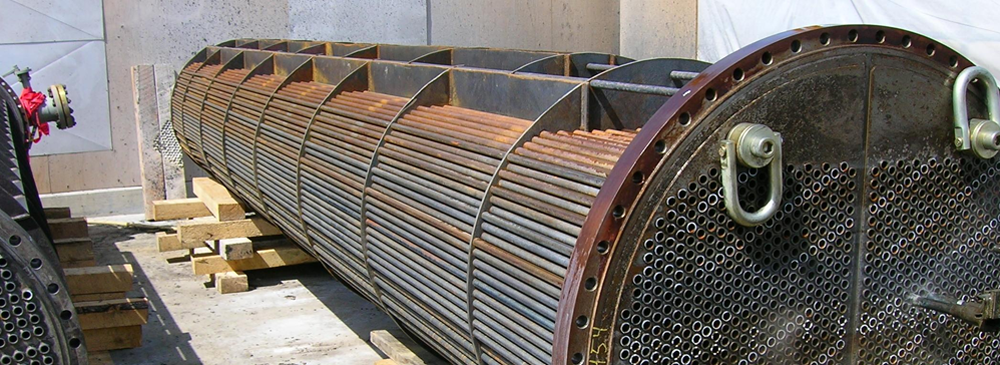

The plant will have a crystallizer with maximum oil-to-heat exchanger area to facilitate the cooling with water. The plant will be designed to give cooling and maximum maturation period to get bold crystals and get good filtration.

Bleached oil is pumped from the storage tank by pump and fed to the crystallizer. This oil is cooled very slowly and gradually to have continuous decrease in temperature at optimum rate to avoid any thermal shook to oil.

This helps to form big crystals. The cooled oil is subjected to required minimum temperature, after the cooling cycle oil is provided with optimum residence/holding time and temperature for maturation of the formed winterized crystal and temperature is maintained to get optimum filtration.

This oil is fed to plate and frame filters by gravity to get the optimum capacity and quality. After filtration of oil the filter are blown with air to get minimum oil in wax.