Heat Exchangers

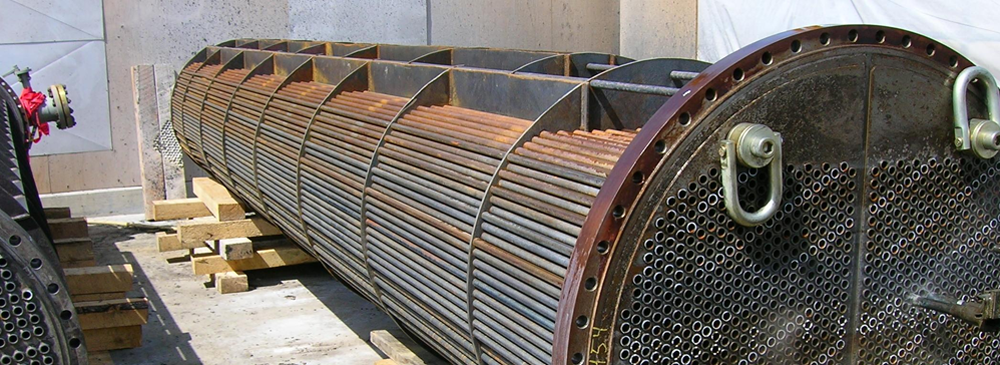

Shell and tube type heat exchangers and condensers are built to the requirements of the ASME code, Section VIII, Division I and in accordance with the tubular exchanger manufacturer’s association (TEMA) standards. Mechanical and thermal design utilizes computerized technology that allows for the optimum performance while considering cost effective space utilization.

1. Shell & Tube Heat Exchangers

2. U â€" Tube Heat Exchangers

3. Scrap Surface Heat Exchangers

4. Condensers

5. Re Boilers

INDUSTRY SEGMENT

• Chemical & Intermediates

• Fertilizers

• Food & Dairy

• Organic Batch Processing

• Petrochemical

• Pharmaceutical & Biotech

• &Pulp & Paper

All units are designed, inspected and tested at our facility, to meet ASME code, Section VIII, Division I and TEMA ‘B’ ‘C’ and ‘R’ standards.

Units are manufactured from a full range of low temperature regular carbon steels, stainless steels, inconels, incoloys, nickels, hastelloys and clad materials.

Complete design, engineering and manufacturing under one roof our modern state of the art, machining centers, automated tube to tubesheet welding, weld preparation grinding equipment and automated welding systems.

Units can be individually designed to customer's material specifications and process parameters. Complete the heat exchanger and condenser specification sheet and submit by e-mail or fax to Brissun for quotation.