Home > Syatems > Air Pollution

Air Pollution

Air Pollution

Air Pollution Control Equipment

Embedded Composite EP Bag Filter

The Embedded Composite EP Bag Filter has the static parts (Collecting and Discharge Electrode) and dust Filter Bags in an alternating arrangement. This is a new dust collecting mechanism where in only charged dust particles pass through the filter bags, thereby reducing the total dust load on the collecting plates in the ESP field. Use of aerosol effect on flue gas charged dust improves the efficiency of the embedded filter bags and protects the bags from the heavy dust load at the entrance to the ESP field.

Most of the coarse dust particles are absorbed on the collecting plate before reaching the Filter Bag which finishes the initial purification of the gas. Further purification of the flue gases take place when it flows through the porous Filter Bags.

During bag cleaning, the collecting plate effectively captures the secondary dust from the bags and reduces the possibility of its reattachment to the filter bags and also reduces the re-entrainment of dust in the incoming flue gases. Collecting plates located on both sides of the filter bag ensure that the process of Electrical corona discharge does not endanger the life of the Bag.

- Suitable for small and medium gas load as compared to conventional EP or Bag Filter, saving 20 to 30% in collecting area of a conventional EP; Less floor space, Less cross sectional area.

- Can achieve emissions less than 30mg/nm3 with lower number of fields.

- Pressure drop is 80mmwg as against 100 to 120mmwg of a conventional Bag Filter.

- Easy Maintenance of Filter Bags and less overall operation and maintenance costs to the tune of less than 40% from conventional EP/Bag Filter.

- Layer of dust formed on Filter Bags in course of time reduces the capacity of dust conveying equipment.

Bag Filter

- Long-bag massive low-pressure pulse Filter.

- The ppw pulse-plenum.

- The fiber glass.

- The LFSF loculatous back blowing.

- The high / low-pressure pulse.

- Bag Filter is widely used in Cement, Electric Power, Steel, Metallurgy, and Chemical industries for material recovery from flue gas.

The Bag Filter is a large dust removal equipment, with the following characteristics:

- Good dust-cleaning effect for large flow rate

- Stable throughout operation

- Easy maintenance

- Lower faults

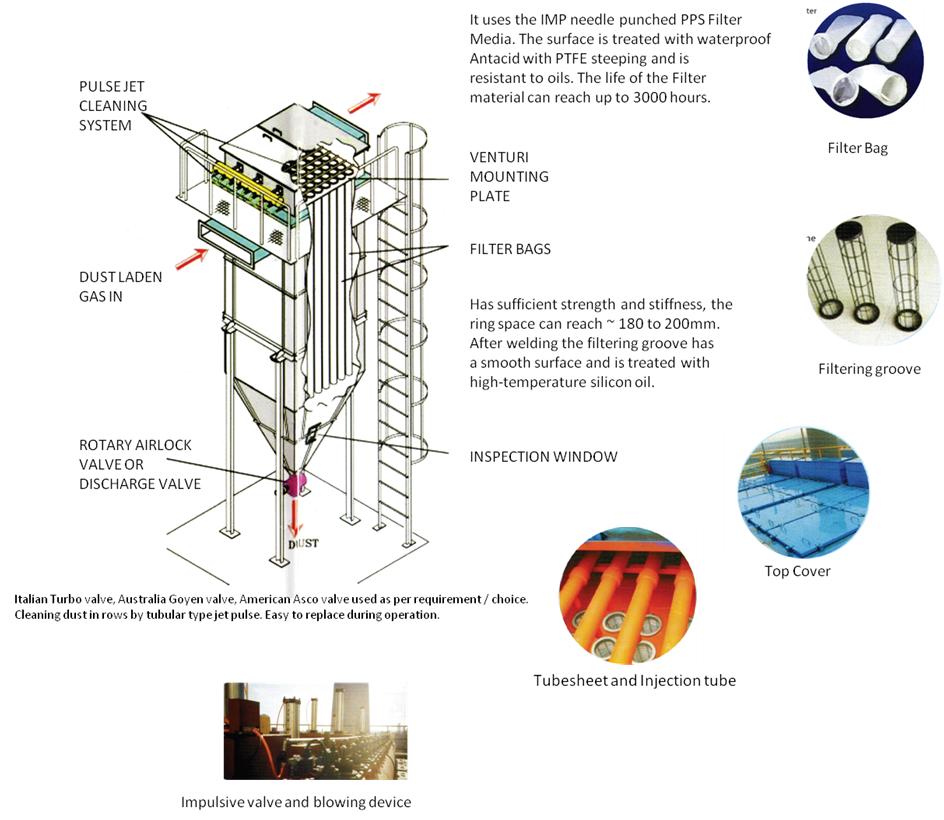

Filter - Main Accessories

Filter Bag

It uses the IMP needle punched PPS Filter Media. The surface is treated with water-proof Antacid with PTFE steeping and is resistant to oils. The life of the Filter material can reach up to 3000 hours.

Filtering Groove Has sufficient strength and stiffness, the ring space can reach ~ 180 to 200mm. After welding the filtering groove has a smooth surface and is treated with high-temperature silicon oil.

Long-bag massive low-pressure pulse filter

- Low-resistance

- Quick start & shutdown

- Large soot-cleaning capacity pulse valves

- Injection pipes of ametorated aerodynamic properties

- Easy assembly & disassembly

- Elastic caulking rings stitched on the mouth of the bags and embedded on the perforated plates

Monitored by microcomputer the long-bag massive low pressure pulse Filter is highly-efficient, reliable, economical, has large capacity, and is convenient to operate.

PPW pulse-plenum bag filter

The PPW pulse-plenum Bag Filter introduced by the H.B. Fuller company, characterized by chambered blow track and pulse soot cleaning, can carry out pulse chambered blow back soot cleaning and filtration respectively with greater intensity and can be applied to more fields than other Bag Filters. Owing to its special structure, its efficiency and service life are increased prominently.

The PPW filter can be installed in Pulverizers, Silo Rooves, Coolers and Mills used in cement factories. Including 33 models, the filters can be divided into the 32-bag, 64-bag, 96-bag and 128-bag in terms of the number of filter bags and 1450mm & 3060mm in terms of length of filter bags. The efficiency of the PPW Filter can reach above 99.98% with the dust concentration of purified gas below 100 mg / Nm.

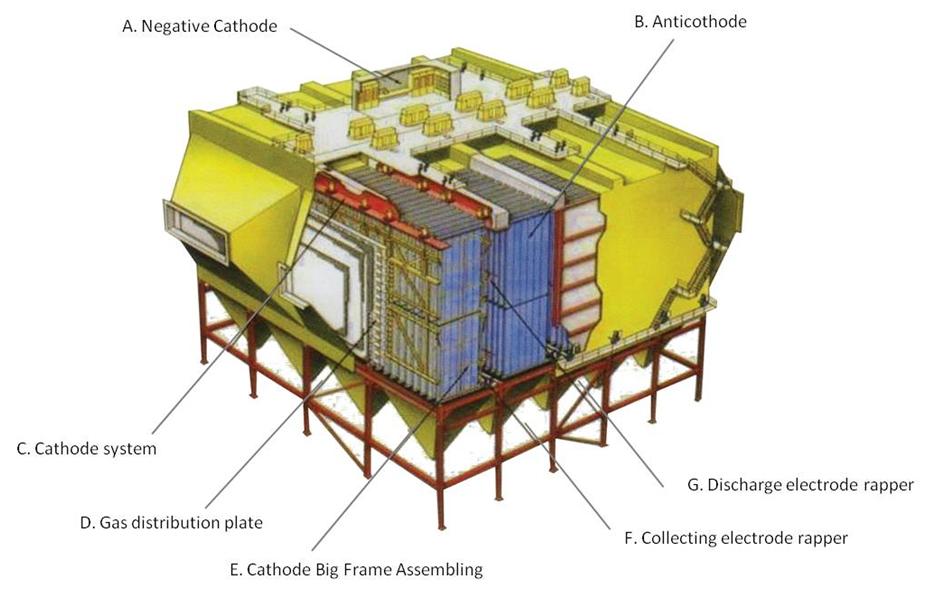

Electrostatic Precipitator

Electrostatic precipitator's are highly efficient filtration devices that minimally impede the flow of gases through the device and can easily remove fine particulate matter such as dust and smoke from the air stream which is applied to the fields such as Cement, Steel, Non Ferrous, and Power industries.

WDL type high-voltage static ESP

Horizontal high-voltage Electrostatic Precipitator is an efficient energy-saving flue gas purification equipment, with:

- High efficiency dust collector to deal with large amount of smoke

- Long life and low maintenance costs

With environmental protection requirements gaining momentum across the globe, the electrostatic precipitator is gaining widespread use.

Features:

- Low resistance

- Well-distributed airflow division

- Stable during operation

- High efficiency