Home > Syatems > "Smart Fog" Dust Control Systems

"Smart Fog" Dust Control Systems

"Smart Fog" Dust Control Systems

Dust Suppression Systems

"SMART FOG" DUST CONTROL SYSTEMS

"Smart Fog" (Dry fog) Dust control system is proposed for controlling the dust generated during the handling material in the Mineral Handling Plant and mineral circuits. The system has been proposed based on the consideration that Micronic Fugitive dust is generated during handling of material, which is hazardous for the people within the work zone and can be controlled effectively by the "Smart Fog" Dust Control System.

PLAIN WATER DUST SUPPRESSION SYSTEM

Raw material handling plants for Iron ore, Gypsum, Lime stone, Bauxite, Flyash, Clinker, Minerals etc. & Coal Handling plants associated with Mines, Steel Plants, Thermal power plants and Cement plants are a potential source of air borne dust, which is a health and safety hazard and also result in loss of material in the form dust. Dust dissemination poses safety, health and environmental problems.

"Water mist" Dust control system uses medium pressure water mist spray through carefully designed hollow cone nozzles for controlling the dust generated at the falling point of hoppers, crushers, storage yards, conveyors etc.

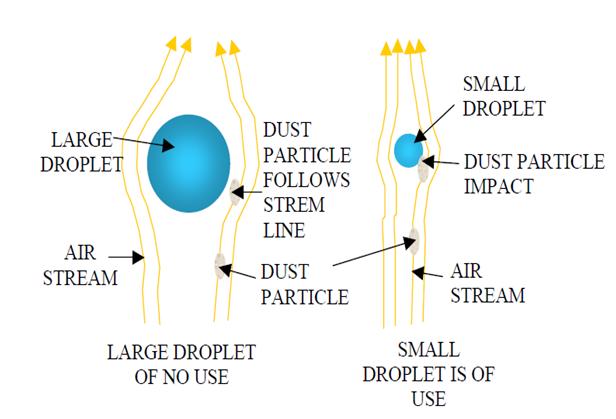

The system works on the principle of "agglomeration" of the dust particles with the mist spray and settling them on the material being handled. These nozzles generate droplet sizes ranging between 100-500 microns to cover the entire range of dust particles.

Material handling plants having long conveyors and several transfer points exposed to heavy winds can be tackled efficiently with this system. To achieve good results, it is essential to properly cover the conveyers, discharge and receipt points etc. In the falling points of the hoppers it is ideal to cover at least 2 or 3 sides and the top to ensure that the wind does not play the spoilsport.

Necessary instruments required for the proper operation of the Dust Suppression System and suitable control devices like solenoid valves or ON/OFF valves are provided to cut off water spray in the event of stoppages of the discharge in the dump hoppers or the stoppage of the plant. These control devices include material sensing units like U/V sensors to cut off the spray when material discharging is not taking place, level switches for refilling water tank, belt load sensors for sensing presence of material in the conveyers etc. These ensure that there is no wastage of water when material handling is not taking place.

Plain water Dust Suppression - Advantages:

- Environmental Friendly as only Water is used for Effective dust control

- Very less water consumption - 80 % compared to conventional spray systems

- No compressed air or steam required for atomization of water (less maintenance)

- 100 % dust control

- Effectively takes care of fugitive dust emission (reduced air pollution)

- Moisture addition less than 1% to the material handled

- No grill choke-ups

- No lump formation on conveyors (saves conveyor from damages)

- No use of costly chemicals for agglomeration of process dust

- Saves fuel (coal) as arrested coal dust captured settles at source

- Clean and pollution free environment

- Wide area coverage

- Fire prevention (cooling coal intern preventing from auto-ignition on conveyors)

- Power saving (Dust Extraction systems can be eradicated)

- Saves costly equipment and machinery from deterioration from dust

SPRINKLER SYSTEMS

The yard sprinkler systems are designed using custom-built sprinklers located on sprinkler posts to cover the height and radius of the stockpile. The system uses Chemtrols Non-lubricated plug valves for isolation of the sprinklers. For auto operation the sprinkler posts are fitted with solenoid valves as well.

Chemtrols' High Performance sprinklers are innovative products designed to rotate at uniform speed over full and part circle applications.

It is equipped with nozzles of various diameters and an adjustable jet-breaker which provides a light and uniform rainfall across the watered area.

The size and features have been designed to obtain the highest efficiency even at operating pressures as low as 1.5 to 2 bar.These sprinklers are available with 230 or 430 trajectory angle for coverage of taller stockpiles.

FEATURES

- Highly energy efficient and covers large area.

- Starts operating from 1.5 to 2 bar water pressure itself, covering 120 to 140 ft.dia. Under sprinkling as per the model, with only 5 H.P.high pump-set. With higher pressure, the dia.increases.

- Uniform sprinkling with provision to adjust size and rain-fall rate to suit the requirement.

- Very light, yet strong due to pressure die-cast aluminum body.

- Angle of rotation adjustable to irrigate all corners.

- One raingun replaces many small sprinklers, saving much in labor and time for irrigation.

- Quick-fit accessories available for connecting to PVC underground mains or HDPE laterals. Telescopic portable stand available for rain-gun mounting at required height.