Ultrasonics

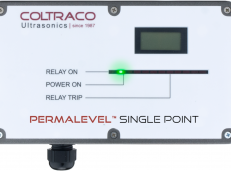

Permalevel Single Point - The Permalevel® Single Point is based on the same technology as the Permaelvel® Multiplex. Instead of monitoring multiple cylinder simultaneously this systems is specially designed to monitor single cylinder systems. Four LEDs show the status of each monitored channel making it easy to manually inspect the condition of each cylinder and the system overall. Standard 4-20mA relay connectors allow the Permalevel® Single Point to integrate with most existing alarm systems, sounding external alarms as well as an optional in-built klaxon inside the Permalevel® Single Point should the system detect a change in a cylinders liquid level. The monitored cylinder has attached to its outer wall its own ultrasonic sensor which is used to monitor the internal liquid level. We have been using our trusted sensor technology for more than 20 years. Our sensors have a strong magnet to hold the sensor in place with additional space for adhesive or a strap to ensure sensors are not accidentally removed. The Permalevel® Single Point can also connect digitally to a computer running bespoke software via a standard RS232 or RS485 connection allowing remote alarms to be triggered, system status to be viewed remotely or for the monitoring settings to be changed via the connected computer.

Portalevel MAX - The UL-approved Portalevel™ MAX is the flagship model in the Portalevel™ range and designed for those operators testing large numbers of cylinders and especially larger clean agent cylinders such as NOVEC™ 1230, FM-200™ and other similar agents, such as HFC 225 & 227, FE-13™, FE-25™, FE-36™ and CO2.

Permalevel Multiplex - The Permalevel® Multiplex has a modular design allowing simple expansion to monitor up to 16 cylinders per control unit. Four LEDs show the status of each monitored channel making it easy to manually inspect the condition of each cylinder and the system overall. Standard 4-20mA relay connectors allow the Permalevel® Multiplex to integrate with most existing alarm systems, sounding external alarms as well as an optional in-built klaxon inside the Permalevel® Multiplex should the system detect a change in a cylinders liquid level. Each monitored cylinder has attached to its outer wall its own ultrasonic sensor which is used to monitor the internal liquid level. We have been using our trusted sensor technology for more than 20 years and these new low profile sensors fit easily between cylinders. Our sensors have a strong magnet to hold the sensor in place with additional space for adhesive or a strap to ensure sensors are not accidentally removed. The Permalevel® Multiplex can also connect digitally to a computer running bespoke software via a standard RS232 or RS485 connection allowing remote alarms to be triggered, system status to be viewed remotely or for the monitoring settings to be changed via the connected computer.