Power Transformer revamping at site

Most economical way to rectify Power Transformer problem is to attend them at site.

Site Repairing of 200 MVA, 400 kV Power TransformerNeed for Site Revamping / Reconditioning of Power Transformers

Site Repairing of 200 MVA, 400 kV Power TransformerNeed for Site Revamping / Reconditioning of Power Transformers

- Power Transformers undergo continuous vibrations making bolted joints, core bolt etc. loose.

- Faults on lines or in Substations produce heavy electrical as well as severe mechanical stresses in Transformers.

a) Excessive electrical stress leads from winding can develop Hot Spot there by damaging the insulation covering.

b) Excessive mechanical stress can make the core bots, pressure bots loose. - Due to aging of oil at higher temperature sludge formation starts.

- Hot Spots are also developed due Partial discharge within Transformer.

- Oil leakages starts due to ageing of Gaskets.

- Transformers wherein a Nitrogen bellow is not used moisture absorption by oil is inevitable, which a affects PI value adversely.

- In case OLTC needs replacement with extension of leads.

In such cases Shifting Transformer to OEM is not economical time wise as well as financially.Since they can be attended at site.

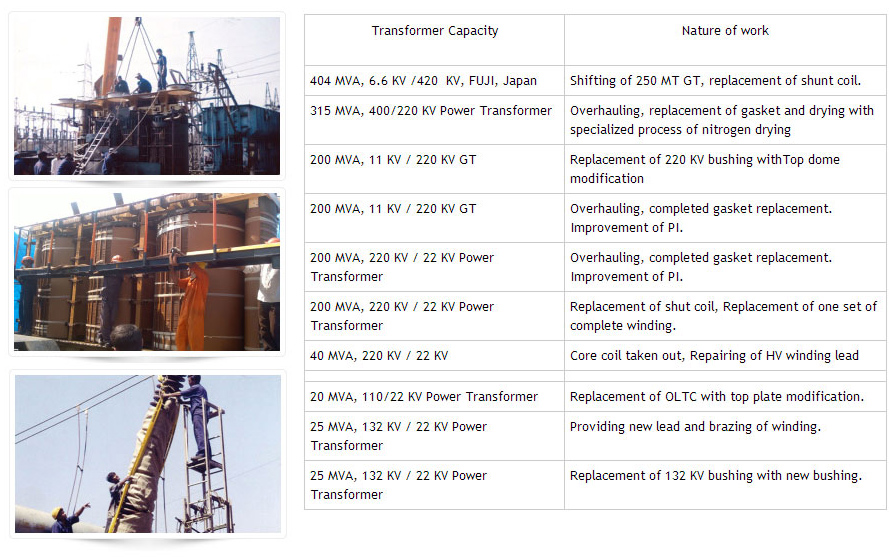

Over a period of last 20 years we have carried out site revamping / repairing / drying out of about 500 Nos. Power Transformer / Generator Transformer ranging from 10 MVA, 132 KV to 404 MVA 420 KV.

Lustre’s Major Site Works of Power Transformer