Fabrication Operations

Fabrication is the building of metal structures by cutting, bending, and assembling .

Cutting is done by sawing, shearing, or chiseling (all with manual and powered variants); torching with hand-held torches (such as torches or plasma torches); and via numerical control (CNC) cutters (using a laser, mill bits, torch, or water jet).

Fabrication is the building of metal structures by cutting, bending, and assembling .

Cutting is done by sawing, shearing, or chiseling (all with manual and powered variants); torching with hand-held torches (such as torches or plasma torches); and via numerical control (CNC) cutters (using a laser, mill bits, torch, or water jet).

» Bending is done by hammering (manual or powered) or via press brakes and similar tools. Modern metal fabricators utilize press brakes to either coin or air-bend metal sheet into form. CNC-controlled back gauges utilized hard stops to position cut parts in order to place bend lines in the correct position. Off-line programming software now makes programming the CNC-controlled press brakes seamless and very efficient.

» Assembling (joining of the pieces) is done by welding, binding with adhesives, riveting, threaded fasteners, or even yet more bending in the form of a crimped seam. Structural steel and sheet metal are the usual starting materials for fabrication, along with the welding wire, flux, and fasteners that will join the cut pieces. As with other manufacturing processes, both human labor and automation are commonly used. The product resulting from fabrication may be called a fabrication. Shops that specialize in this type of metal work are called fab shops. The end products of other common types of metalworking, such as machining, metal stamping, forging, and casting, may be similar in shape and function, but those processes are not classified as fabrication.Fabrication comprises or overlaps with various metalworking specialties:

» Fabrication shops and machine shops have overlapping capabilities, but fabrication shops generally concentrate on metal preparation and assembly as described above. By comparison, machine shops also cut metal, but they are more concerned with the machining of parts on machine tools. Firms that encompass both fab work and machining are also common.

» Blacksmithing has always involved fabrication, although it was not always called by that name.

» The products produced by welders, which are often referred to as weldments, are an example of fabrication.

» Boilermakers originally specialized in boilers, leading to their trade's name, but the term as used today has a broader meaning.

» Similarly, millwrights originally specialized in setting up grain mills and saw mills, but today they may be called upon for a broad range of fabrication work.

» Ironworkers, also known as steel erectors, also engage in fabrication. Often the fabrications for structural work begin as prefabricated segments in a fab shop, then are moved to the site bytruck, rail, or barge, and finally are installed by erectors.

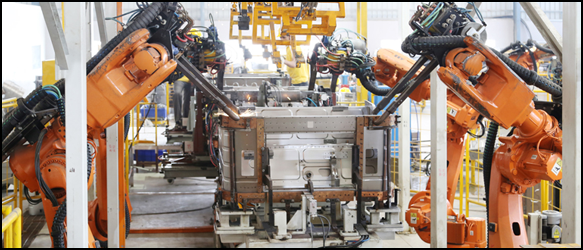

• Assembly Operations

Industries specializes in Windshield assembly of various metal components, cold formed, machined, extruded metal and plastic parts for the automotive, industrial, electronic, and energy markets. After we have manufactured many of your sub-components, our customers can take advantage of our mechanical assembly expertise at one of our North American facilities or our low cost country mechanical assembly plant located in Bangalore India. With MultiTech assembling these subcomponents into working parts for our customers they can in turn focus on the more complicated final assembly of their product.

• Overview / Process

The windshield or windscreen of an aircraft, car, bus, or tram is the front window. Modern windshields are generally made of laminated safety glass, a type of treated glass, which consists of two (typically) curved sheets of glass with a plastic layer laminated between them for safety, and are bonded into the window frame. 3 Wheeler and 4 Wheeler windshields are often made of high-impact acrylic plastic.

After laminating, the windshield is ready to be assembled with plastic moldings so it can be installed on the car. Known as glass encapsulation, this assembly process is usually done at the glass manufacturer. First, the peripheral section of the windshield is set in a predetermined position in a mold cavity. Next, molten plastic is injected into the mold; when it cools, it forms a plastic frame around the glass. The windshield assembly is then shipped to the car manufacturer, where it is installed in an automobile. The installation is done by direct glazing, a process that uses a polyurethane adhesive to bond the windshield and automobile body.

• Product Suits

3 Wheeler Windshields