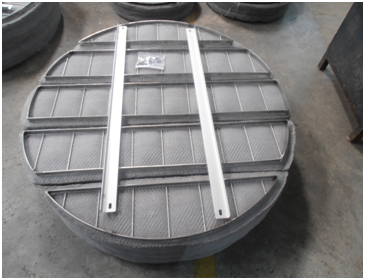

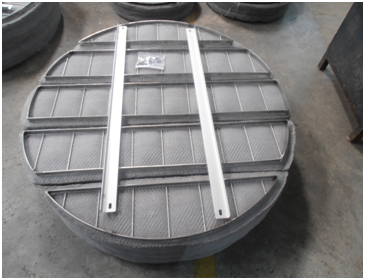

Whenever there is a contact between gas and liquid in the column, there will be maximum chances of entrainment. It’s just the entrapment of one substance by another one along with contaminants. Such mist and liquid droplets cannot be vented directly into the atmosphere. And it can lead to serious losses of the process fluid and equipment damage in mass transfer operations. This entrained component can be easily get separated by using demister pad. This pad can directly convert entrained vapors/mist into liquid and traps the vapors to get vented off with gas. It helps to collect entrained vapors in the form of liquid drops and separates them from a gaseous mixture. The main working principle of Demister is to separate liquid by coalescing smaller liquid droplets from the gasses and allowing them to get a drop into the liquid pool. demister-pad Coalescing of smaller liquid droplets is due to different types of obstructions made in the path of vapors. It allows vapors to pass through obstruction where the pressure drops created in the vapor lead to the formation of the liquid droplet, and only gasses flow from the demister device by mechanical separation. Demister pad can also be called a mist eliminator, mist pad, wire mesh demister, catching mist, and mesh mist eliminator also. Demister pad can install directly on the outlet of the top vapor or at the top of the packing tower. S-cube Mass Transfer is India’s leading manufacturer and supplier of Demister Pad and Mist Eliminator!

Application of Demister Pad

Distillation columns

Absorption columns

Oil Mist Separation

Steam Boilers

Gas and Air scrubbers

Knockout Drums

Effluent gas treatment in Sulphuric Acid Factories

Vacuum Towers and Drying Towers.

Mist Eliminator

Mist Elimination, the removal of liquid droplets from the vapour is one of the most commonly encountered processes. Unfortunately, Mist Eliminators are the most ignored commodities to available technologies and design parameters. The well-engineered mist eliminators can reduce liquid carryover by a factor of one hundred or more relative to a standard unit, drop head losses by more than 50%, and increases capacity by factors of three or four. The overall approach is for cost-effective operation by avoiding solvent losses, emissions and extending equipment life and maintenance cycles using proven and cost-effective techniques.

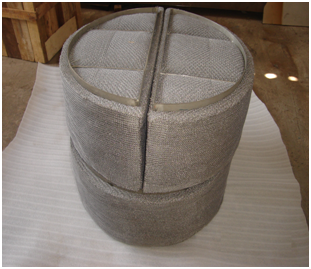

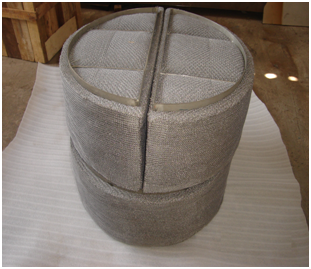

Specifications

Simple structure

Lightweight and easy to transport

High porosity, less pressure drops

Large surface area and high separating efficiency

Easy to install, operate and maintain

Durable and long service life

Corrosion and rust resistance