Type of Stripper Column

Our process specialists can support you with optimally designed stripping columns. We supply firstclass components and equipment, or entire plant solutions, providing you with an excellent performance/cost ratio. Stripper Column is a part of zero Liquid Discharge system.

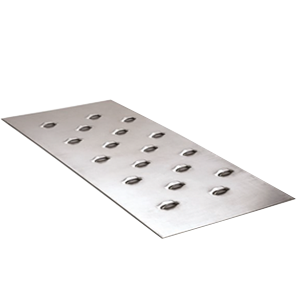

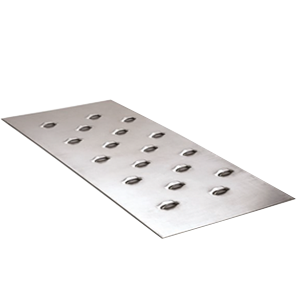

Structure Packing with Trays - This type is specially used with below feed for high TDS or Solid concentration.

Stripper Column with Total Trays - This type is used for very high TDS & cleaning frequency 10 days.

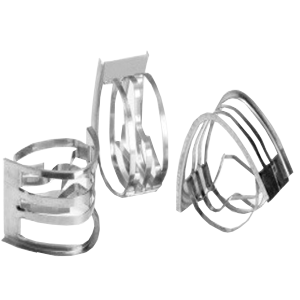

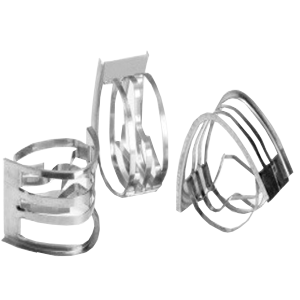

Structured Packing & Random Packing below feed used for the less TDS feed.

Process

This basic operation in fluid processing serves to remove one or more lighter components from a liquid mixture. These components can be dissolved gases or lighter chemicals. The purpose of this process is typically to recover products from a liquid phase or to remove pollutants from wastewater. S Cube has extensive experience in the successful design of stripping systems, especially combining a stripping step to remove solvents from wastewater with additional processing steps to purify these solvents.

Main benefits

The design of stripping units is geared to provide you with improved column performance, increased capacity and reduced energy consumption. Design activities are supported by computer simulations and in-house pilot plant testing. Our vast experience and know-how in the field of stripping combined with an in-depth understanding of column hardware ensures we provide you with the optimum solution.

Offering

We offer you complete lines of column internals, packing or trays that can satisfy any stripping requirement, together with a basic engineering package and other key equipment such as column shells, column packings & internals, heat exchangers, and decanters. You can also choose the delivery of a complete, often skid-mounted unit including process control and start-up support services.