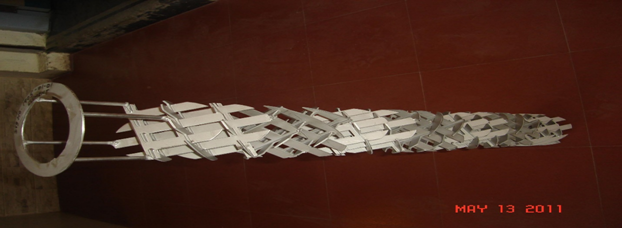

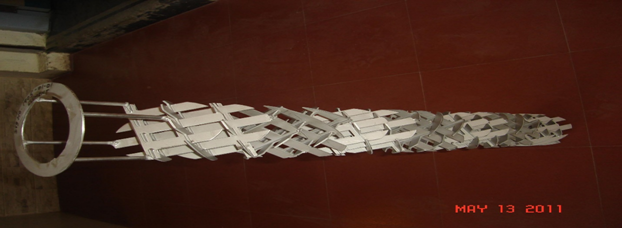

Static Mixer

High Efficiency SMX element

Static mixers help to get the desired mixing of two or more components without moving of equipment. These mixers are also specialized for the continuous mixing of components with perfect-mannered mixing quality. The compact structure of the static mixer mixes the streams of fluids into housing and pipelines. Adequate mixing in such a compact area can be obtained by inserting a static mixer only. It differentiates itself with its stable and fixed nature, unlike traditional mixers. Here we offer optimized blending technology for fluids as well as gasses with less energy consumption. Our efficient mixers are fully developed and manufactured to only satisfy and justify industrial needs.

S-Cube Mass Transfer India provides Static Mixing Technology widely used in the fluid processing industry. We are one of the best Static Mixer suppliers in Pune, India.

Working Principle of Static Mixer

Static mixing assure that mixing can be achieved in short pipe length and in motionless operation. The efficiency of a static mixer depends on the angular arrangement of elements. Mixing elements are serially arranged one after another to get a homogeneously mixed outlet throughout. Various angles mixing elements divide and Recombine the streams through the mixer to achieve the required homogeneous mixture. Process requirements and specific properties such as density, the viscosity of fluid stream, and degree of mixing of mixture are the factors that decide the number of mixing elements required in a mixer.

Chemical Industry

Distribution of immiscible liquids in various washing and extraction operations

Mixing gases with the air in front of catalytic reactors such as in the Nitric Acid production process.

Dissolving gases into liquids such as NH3, SO2, Cl2

Mixing Reactive materials in short length/Space

Heating and Cooling of the viscous materials

Water & Wastewater Treatment

Controlling pH of waste water with acids/bases

Dilution of Flocculants and addition of it to waste water

For Dissolving purpose of CO2, O2, Cl2 and Ozone into water

For Mixing ground and surface waters

Aerated drinking water processes

Other Industries

Natural Gas Processing

Pulp & Paper Processing

Cosmetics & Detergents

Potable Water Treatment

Catalyst Manufacture and Catalytic Reactors

Minerals & Ore Processing

Vegetable Oil Processing

Reverse Osmosis Feed Pretreatment

Scrub Noxious Gases with caustic