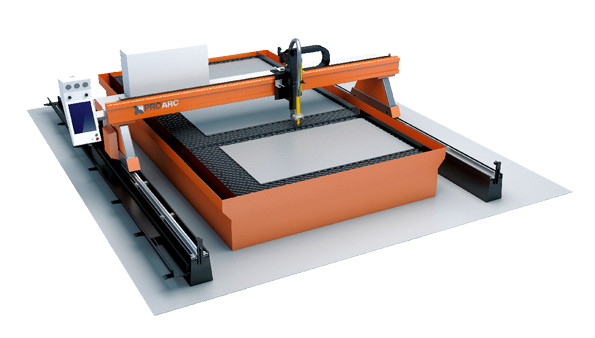

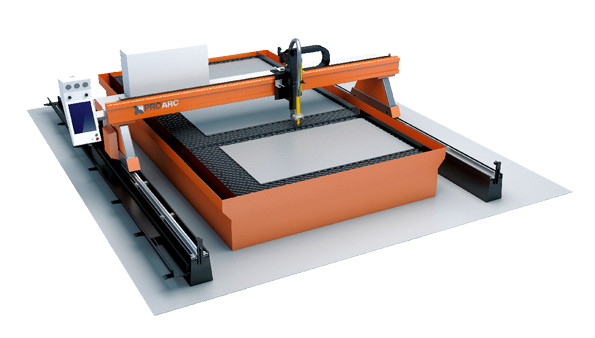

Inferno Enduro

More value in every cut

Enduro is a high-performance cutting solution that is also cost-effective. Through its precise motion, ergonomic design and compact footprint, Enduro brings speed and productivity to all types of fabricators.

Processes

Plate cutting

Marking

- Moderate gantry design supported on elevator rails

- Built with sturdy components to ensure high reliability

- Roller guide on Aluminium extrusion mounted on the gantry for precise motion of torch stations

- Spur racks and pinions for precise motion

- Power transmission along X & Y axes through digital AC servomotors and low backlash planetary gearboxes

- Dual synchronized servo motors for gantry motion along longitudinal direction

- Ball screw slides for precise vertical motion of torches

- Auto plate alignment for reduced setup time

- Collision protection for plasma heads

- Enhanced safety features

| Model | Enduro | |

|---|---|---|

| Processes | Oxy-fuel and/or Plasma | |

| Application | Light to medium duty cutting, profile cutting, air plasma cutting | |

| Machine Structure | Gantry simply supported at both ends by elevator rails | |

| Working widths | 1,500 mm - 3,000 mm | |

| Maximum Working length | 16,000 mm | |

| Lifter Stroke | 100 mm | |

| Cutting Capacity: | ||

| Oxy-fuel | 6 mm - 100 mm | |

| Plasma |

0.5 mm – 50 mm MS 1 mm – 40 mm SS 1 mm – 40 mm Al Cutting thickness depends on the plasma system offered |

|

| Maximum plasma torches | 1 | |

| Maximum oxy-fuel torches | 2 | |

| Maximum Positioning Speed | 12,000 mm/min | |

| X & Y axes motion | Spur Rack and pinion | |

| Z axis motion | Ball screw | |

| Guiding mechanism | Guide bar roller system on cross axis & cam follower arrangement for long axis with elevator rails. | |

| Cutting accuracy and dimensional tolerance | ISO 9013 class 2 | |

| Operator HMI | Keypad based HMI, switches on operator panel | |

| CNC Controller | ARM-based controller | |

Certain customizations are possible in the above machines.

Inferno - Enduro