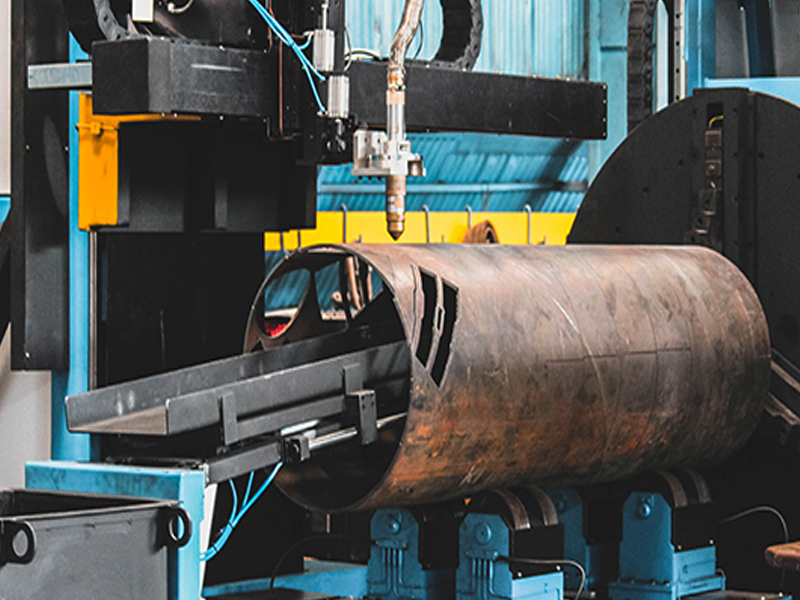

The epitome of flexibility and dependability

The Slash cutting machine is designed for processing high volumes of circular pipes and square and rectangular tubes, mostly for structural fabrication. The CNC controller and nesting software have standard shape libraries for achieving a variety of cuts, miters, copes, saddles, hillsides and more. Its robust frame has been engineered to deliver years of unmatched performance and high accuracies.

Processes

Plate cutting

Pipe Beveling

- Head stock with self-centring chuck for gripping and rotating the pipes/ tubes

- Built with sturdy components to ensure high reliability

- Option of stationary headstock and moving cutting carriage or stationary cutting carriage and moving headstock

- Cutting achieved through interpolation of rotary axis of chuck, axial motion of chuck/ cutting carriage, vertical motion of torch

- Power transmission through digital AC servomotors and low backlash planetary gearboxes

- Option of manual/ pneumatic/ hydraulic clamping of jaws

- Ball screw slides for precise vertical motion of torches

- Collision protection for plasma heads

- Enhanced safety features

| Model | Slash | |

|---|---|---|

| Processes | Oxy-Fuel / Plasma | |

| Application | Pipe / square and rectangular tube cutting | |

| Machine Structure | Headstock with chuck, idlers for supporting pipe/ tube and cutting carriage | |

| Pipe diameters |

ø 50 mm – 300 mm ø 50 mm – 500 mm |

|

| Max. Square Tube sizes |

50 mm to 200 mm sq. 75 mm to 300 mm sq. |

|

| Pipe / Tube length |

6,000 mm 12,000 mm |

|

| Wall thickness | 2 to 30 mm | |

| Maximum pipe / tube weight | 2,000 kg | |

| Maximum cutting speed on pie | 4,000 mm/min | |

| Chuck Clamping | Manual / Pneumatic / Hydraulic | |

Certain customizations are possible in the above machines.

Inferno - Slash

Inferno - Slash

Inferno - Slash