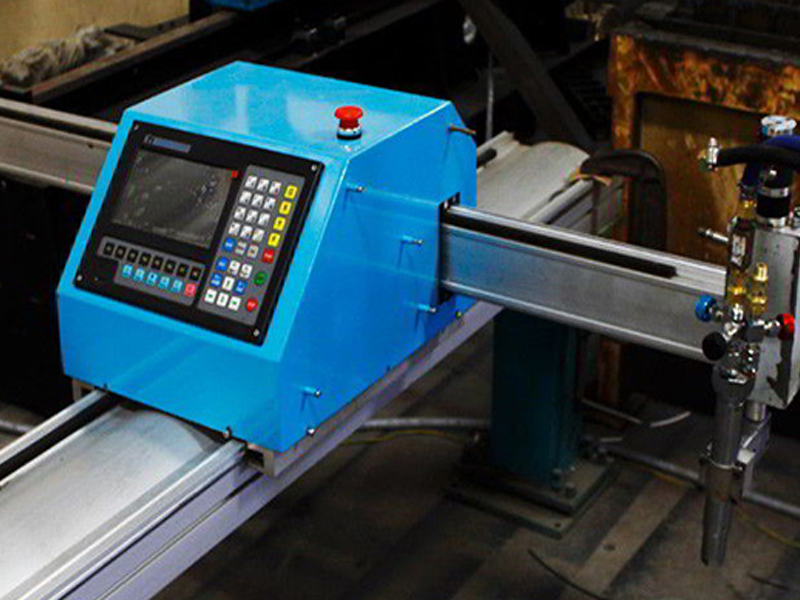

The first step towards cutting automation

Uno is an economical solution for fabricators across all industries. A portable cantilever machine useful for oxyfuel and plasma cutting processes, ergonomically designed for optimum space utilization. Uno is ideal for businesses looking to transition to cutting automation.

Processes

Plate cutting

- Cantilever aluminium extrusion moving over aluminium track

- Light-duty spur racks for gantry motion

- Stepper motors for axes motion

- ARM-based CNC controller

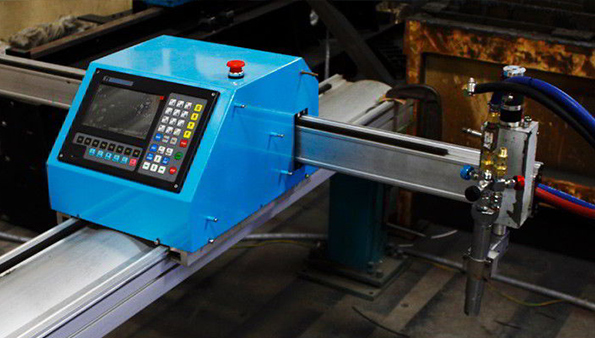

| Model | Uno | |

|---|---|---|

| Processes | Oxy-fuel and/or Plasma | |

| Application | Light duty cutting, low volumes of profile cutting requirement | |

| Machine Structure | Cantilever aluminium extrusion moving over aluminium track | |

| Working widths | 1500 mm | |

| Maximum Working length | 6000 mm | |

| Cutting Capacity: | ||

| Oxy-fuel | 6 mm - 60 mm | |

| Plasma |

0.5 mm – 25 mm MS 1 mm – 20 mm SS 1 mm – 20 mm Al Cutting thickness depends on the plasma system offered |

|

| Maximum plasma torches | 1 | |

| Maximum oxy-fuel torches | 1 | |

| Maximum Positioning Speed | 6,000 mm/min | |

| X & Y axes motion | Spur Rack and pinion | |

| Z axis motion | Lead screw | |

| Guiding mechanism | Aluminium cantilever arm slides on the aluminium track | |

| Cutting accuracy and dimensional tolerance | ISO 9013 class 2 | |

| Operator HMI | Keypad based HMI | |

| CNC Controller | ARM-based controller | |

Certain customizations are possible in the above machines.

Inferno - Uno

Inferno - Uno