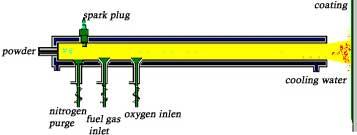

Detonation Spray

Oxygen and fuel (acetylene most common) is fed into the barrel along with a charge of powder. A spark is used to ignite the gas mixture and the resulting detonation heats and accelerates the powder to supersonic velocity down the barrel. A pulse of nitrogen is used to purge the barrel after each detonation. This process is repeated many times a second. The high kinetic energy of the hot powder particles on impact with the substrate results in build up of a very dense and strong coating.

Characteristics of Detonation Spray Coating:

| Material Form | Powder |

| Heat Source | Charge Detonation |

| Flame Temperature (°C) | 3000 to 4000 |

| Gas Velocity (m/sec) | > 1500 |

| Porosity (%) | < 1 |

| Coating Adhesion (MPa) | > 70 |

Advantages:

- Excellent bond strength

- Very dense coatings

- Porosity less than 1%

- Better coating characteristics of hardness,wear & corrosion resistance

- Versatile process, ensuring wide range of coatings

- Low process temperature enables spraying of precision components

- Higher thickness coatings easily possible

- Process can be easily automated