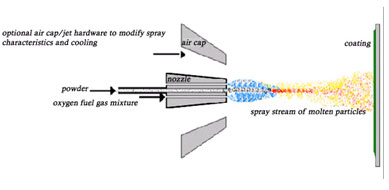

Powder Flame Spray

Material in powder form is melted in a flame (Oxy-Acetylene or Hydrogen most common) to form a fine spray. When the spray contacts the prepared surface of a substrate material, the fine molten droplets rapidly solidify forming a coating.

The main advantage of this process over the similar wire flame spray process is that a much wider range of materials can be easily processed into powder form giving a larger choice of coatings.

Characteristics of Powder Flame Spray

| Material Form | Powder |

| Heat Source | Oxy-Fuel Combustion |

| Flame Temperature (°C) | 3000 |

| Gas Velocity (m/sec) | < 300 |

| Porosity (%) | 10 to 15 |

| Coating Adhesion (MPa) | 14 to 21 |

Advantages:

- High production spray rates

- Easy to operate & portable

- Large choice of coating materials

- Can be easily automated