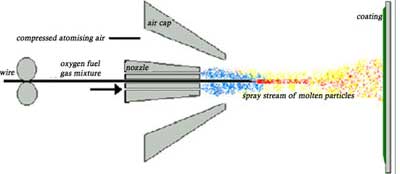

Wire Flame Spray

The process is basically the spraying of molten metal onto a surface to provide a coating. Material in wire form is melted in a flame (Oxy-Acetylene flame most common) & atomised using compressed air to form a fine spray. When the spray contacts the prepared surface material, the fine molten dropletsw rapidly solidify forming a coating.

Characteristics of Wire Flame Spray

| Material Form | Wire |

| Heat Source | Oxy-Fuel Combustion |

| Flame Temperature (°C) | 3000 |

| Gas Velocity (m/sec) | < 300 |

| Porosity (%) | 10 to 15 |

| Coating Adhesion (MPa) | 14 to 21 |

Advantages:

- Simple to operate

- Wire form cheaper than powder

- Very high deposit efficiency

- It has a portable system and can be used in areas without electricity

- Possibly still best for applying pure Molybdenum coatings

Disadvantages:

- Limited to spraying material supplied in wire or rod form

- Coatings have higher porosity and lower bond strength

- Not capable of spraying low oxide, high density & high strength coatings