Wire Arc Spray

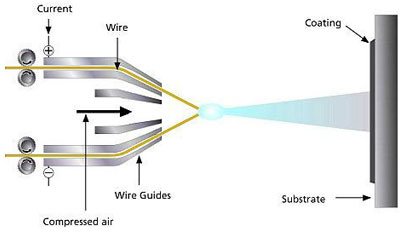

This form of thermal spraying uses wire material as a feed stock. An electric arc is used as the heat source. As the wires are fed towards each other, an electric arc is struck between the wires creating a temperature of around 4,000°C.

This temperature causes the tips of the wire to melt and once molten state, a stream of compressed air or inert gas is used to atomise and accelerate the feed metal towards the substrate.

Characterestics of Wire Flame Spray

| Material Form | Wire |

| Heat Source | Electric Arc |

| Flame Temperature (°C) | 3600 to 4000 |

| Gas Velocity (m/sec) | < 300 |

| Porosity (%) | 10 to 15 |

| Coating Adhesion (MPa) | 28 to 42 |

Advantages:

- Coatings with good characteristics can be achieved

- Two different wires can be used simultaneously to produce a pseudo alloy

- Cored wires are also available producing coatings with unique properties

- Applying coating to large areas is easier by this process

- Used for dimensional restoration due to higher deposit efficiency

Disadvantages:

- Coatings achieved are not dense and have porosity of up to 15%

- Good suface preparation is very essential for good bond strength

- Coatings limited to materials available in wire form with low melting tempertaure