Engineering Plastics: Handling Chemicals with Confidence in Chemical Processing

The chemical processing industry deals with a vast array of aggressive chemicals, demanding robust materials that can withstand harsh environments. Engineering plastics are proving their worth in this sector due to their properties that ensure safe and efficient chemical handling:

Chemical Resistance:

Unlike metals, many engineering plastics exhibit excellent resistance to a wide range of chemicals, including acids, bases, and solvents. This minimizes corrosion and degradation, ensuring the integrity of equipment and preventing leaks or contamination.

Lightweight:

Compared to traditional materials like stainless steel, engineering plastics offer significant weight reduction. This translates to lighter tanks, pipes, and valves, making them easier to handle and potentially reducing overall system weight.

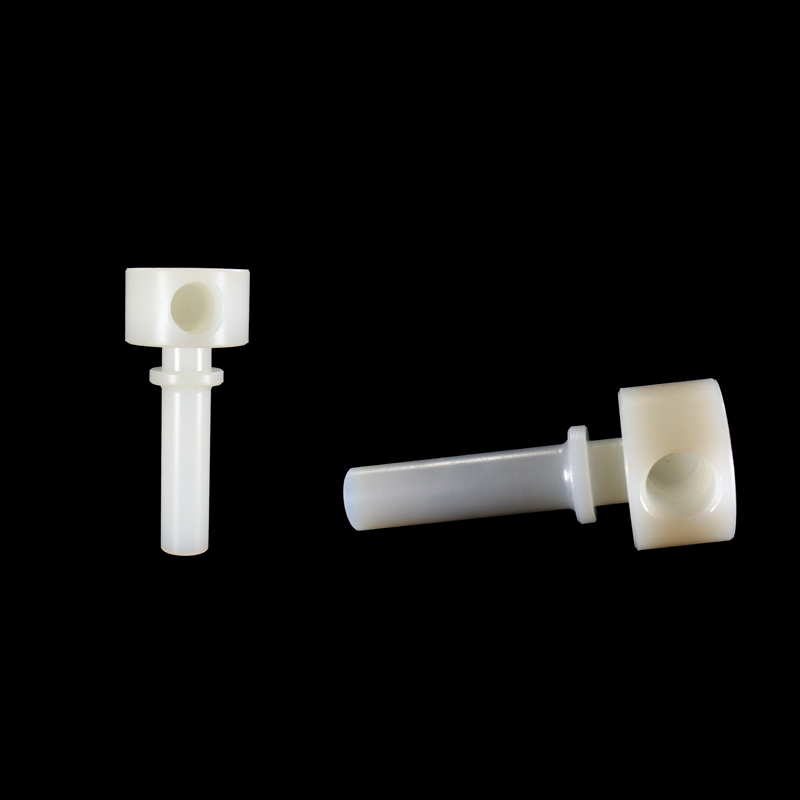

High Strength and Wear Resistance:

Certain engineering plastics possess exceptional strength and wear resistance. This allows them to handle the pressure and abrasive nature of chemical processing environments without compromising performance.

Smooth Surfaces:

The smooth surfaces of some engineering plastics minimize buildup and promote easier cleaning, reducing the risk of contamination and improving hygiene.

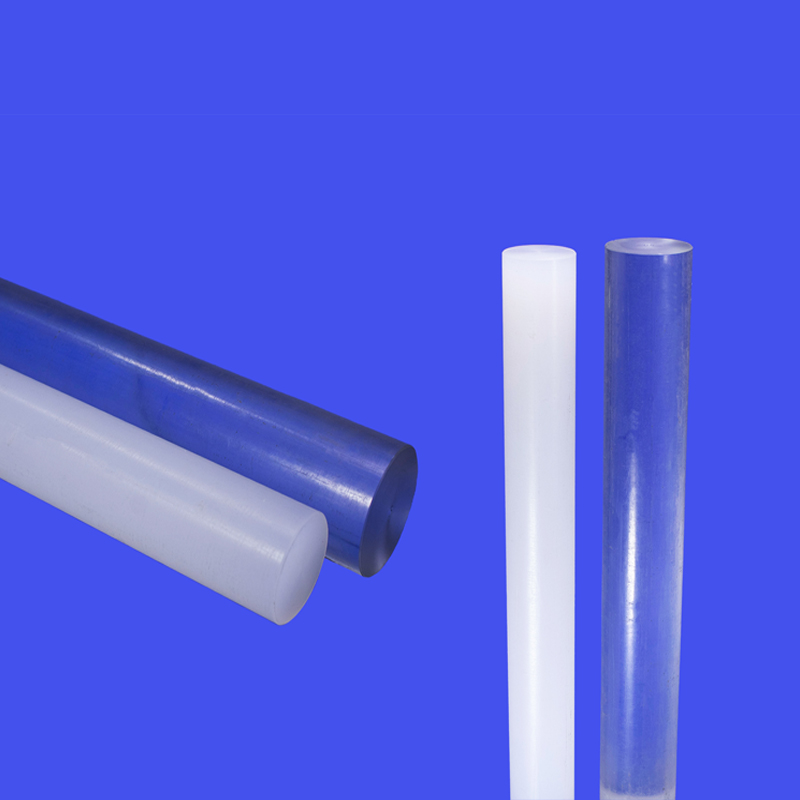

Transparency:

Certain plastics are transparent, allowing for visual inspection of processes and chemical flow within tanks and pipes.

These properties translate to several advantages for the chemical processing industry:

Enhanced Safety:

Chemical resistance minimizes the risk of leaks and equipment failure, leading to a safer work environment.

Improved Efficiency:

Lighter weight components can potentially reduce energy consumption during operation and maintenance.

Reduced Maintenance Costs:

Corrosion resistance and wear resistance minimize the need for frequent replacements and repairs.

Easy Cleaning:

Smooth surfaces facilitate easier cleaning and decontamination, reducing downtime and promoting hygiene.

Cost Savings:

While the initial cost per unit weight might be higher than metal, the benefits of safety, lower maintenance, and potentially longer lifespan contribute to a lower total cost of ownership.

In conclusion, engineering plastics are playing a vital role in the chemical processing industry by enabling safer, more efficient, and potentially more cost-effective operations through their superior chemical resistance, lighter weight, and ease of maintenance.

Materials list