Engineering Plastics: Shaping a Healthier Future in Medical Devices

Medical devices play a vital role in modern healthcare, demanding materials that prioritize patient safety and functionality. Engineering plastics have become a cornerstone in this industry due to their properties that meet these critical needs:

Biocompatibility:

Certain engineering plastics are biocompatible, meaning they are inert and non-toxic when implanted in the body, minimizing the risk of rejection or adverse tissue reactions.

Sterilizability:

They can withstand various sterilization methods like autoclaving and radiation, ensuring sterility and reducing the risk of infection.

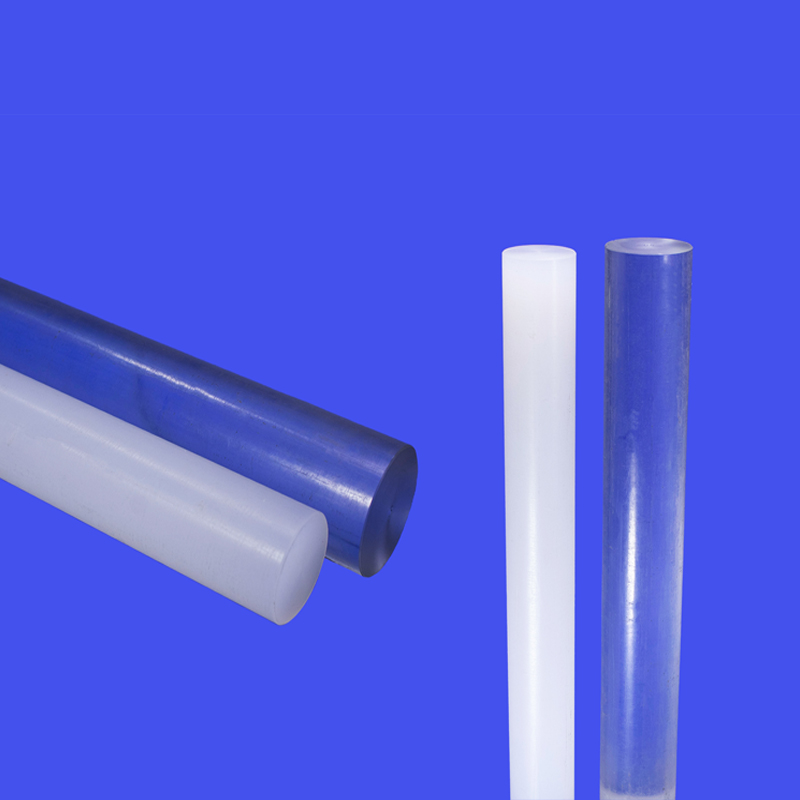

Translucency:

Certain engineering plastics can be translucent, allowing for visualization of internal components in some devices.

Strength and Durability:

Engineering plastics offer a range of strength and flexibility options, allowing for the creation of devices that are both strong enough for their intended purpose and flexible for patient comfort.

Lightweight:

Compared to metal, some plastics offer significant weight reduction, making devices like prosthetics and implants lighter and potentially more comfortable for patients.

These properties translate to several advantages for the medical device industry:

Improved Patient Outcomes:

Biocompatibility and sterilizability minimize the risk of complications and infections, leading to better patient outcomes.

Enhanced Patient Comfort:

Lighter weight materials and flexibility can contribute to increased patient comfort with medical devices.

Broader Range of Applications:

The versatility of engineering plastics allows for the creation of a wider variety of medical devices with diverse functionalities.

Cost-Effectiveness:

While the initial material cost might be higher than some traditional materials, the benefits of biocompatibility, sterilizability, and potentially longer lifespan can lead to a lower total cost of ownership for some devices.

Overall, engineering plastics are transforming the medical device industry by enabling the development of safer, more comfortable, and potentially more cost-effective devices that contribute to improved patient care and a healthier future.

Materials list