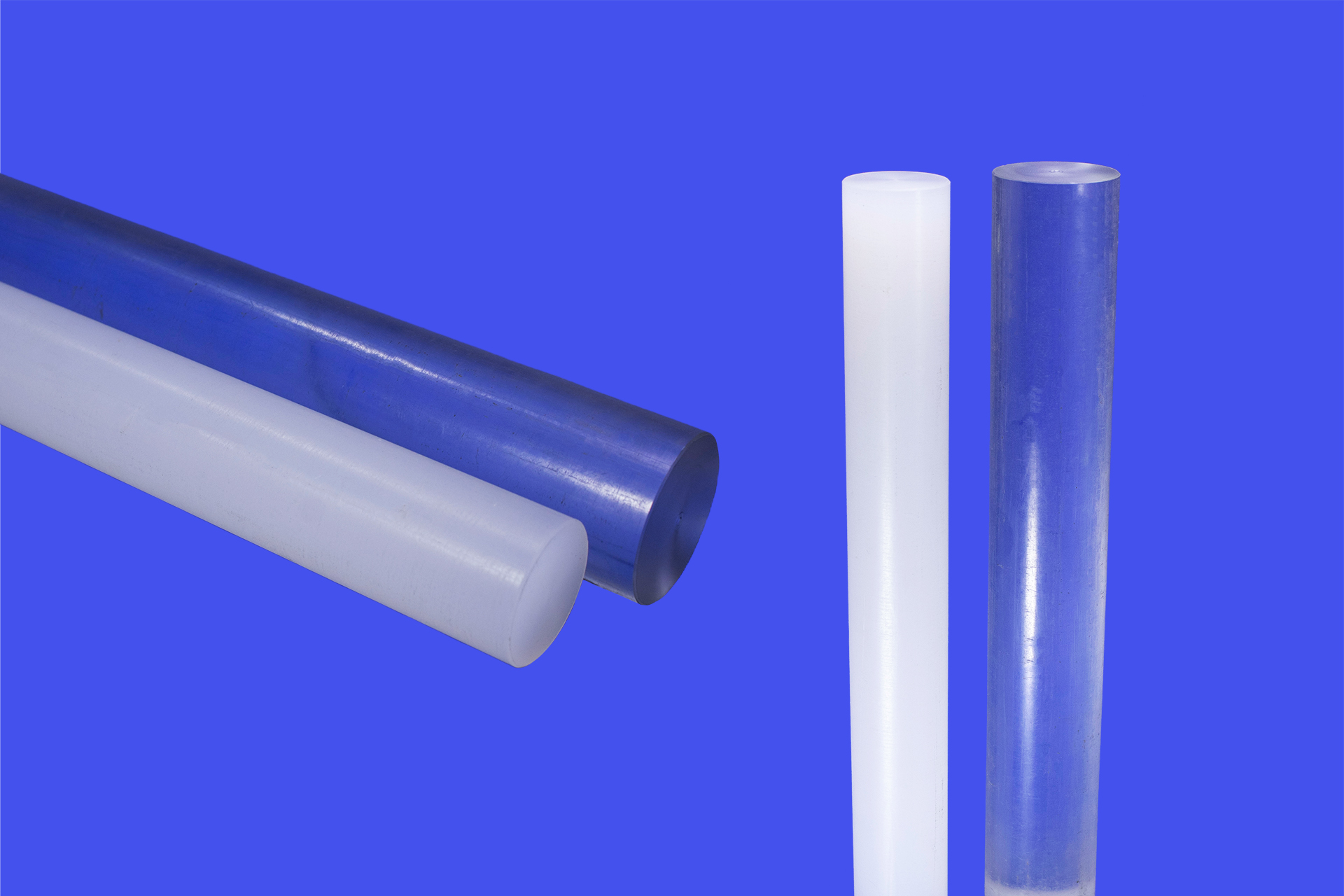

Polymat Polycarbonate

Polycarbonate (PC) is a high-performance thermoplastic renowned for its outstanding impact resistance, optical clarity, and thermal stability. Polycarbonate is extensively used across various industries, including automotive, aerospace, electronics, and medical sectors, consumer goods due to its exceptional properties.

Mechanical Properties

- Tensile Strength: Polycarbonate exhibits high tensile strength, typically around 60-70 MPa (megapascals), which allows it to withstand significant stretching forces without breaking.

- Impact Resistance: It has an exceptional impact resistance, often quoted as being up to 200-250 times stronger than glass. Its notched Izod impact strength is around 600-900 J/m (joules per meter).

- Flexural Strength: Polycarbonate has a flexural strength of approximately 90-100 MPa, meaning it can resist bending under load.

- Impact Strength: Moderate impact resistance, which can vary depending on the specific grade and conditions of use.

- Hardness: Polycarbonate typically has a Rockwell hardness of around R118, indicating a high resistance to surface deformation

Thermal Properties

- Glass Transition Temperature (Tg): The glass transition temperature of polycarbonate is around 147°C, which is the temperature at which it transitions from a hard, glassy material to a softer, rubbery state.

- Melting Temperature (Tm): Polycarbonate does not have a sharp melting point but typically becomes pliable at temperatures above 155-160°C.

- Thermal Decomposition: Polycarbonate begins to thermally decompose at temperatures above 280°C.

- Thermal Conductivity: It has low thermal conductivity, approximately 0.19 W/m·K (watts per meter per kelvin), making it a good insulator.

Chemical Properties

- Acids: Polycarbonate has moderate resistance to acids. It can withstand exposure to dilute acids such as acetic acid and citric acid without significant degradation. However, concentrated acids, especially strong mineral acids like sulfuric and hydrochloric acids, can cause degradation over time.

- Bases: Polycarbonate generally exhibits poor resistance to strong bases. Alkaline solutions, particularly those with high concentrations like sodium hydroxide or potassium hydroxide, can cause stress cracking and deterioration of the material.

- Solvents: Polycarbonate is susceptible to attack by various organic solvents. It can be damaged by solvents such as acetone, chloroform, and methylene chloride. Prolonged exposure to these solvents can lead to surface crazing, swelling, or cracking.

- Oxidizing Agents: The material has limited resistance to oxidizing agents. Strong oxidizers like hydrogen peroxide or chlorine bleach can cause chemical degradation and compromise the material’s structural integrity.

- Hydrolysis: Polycarbonate is sensitive to hydrolysis, particularly under conditions of high temperature and moisture. Prolonged exposure to water, especially at elevated temperatures, can lead to degradation, which is sometimes referred to as "hydrolytic cleavage."

- Fuel and Oils: Polycarbonate has limited resistance to fuels and oils. It can be affected by exposure to hydrocarbons and various lubricants, which may cause swelling or degradation.

- Detergents and Cleaning Agents: The material can generally withstand exposure to mild detergents and cleaning agents. However, strong or abrasive cleaners can cause surface damage or discoloration.

Industrial Applications

Automotive Parts

Used for headlamp lenses, interior panels, and other components due to its impact resistance and optical clarity.

Construction

Polycarbonate panels are used in roofing, skylights, and glazing systems. They provide excellent light transmission and are durable against weather conditions.

Electronics

Used in housings and casings for electronic devices because of its high impact resistance and ability to be molded into complex shapes.

Medical Devices

Polycarbonate is used in various medical devices and equipment because it's sterilizable and has good dimensional stability.

Aerospace

Components in aircraft and spacecraft benefit from polycarbonate's lightweight and strength properties.

Safety Gear

It’s used in protective eyewear, helmets, and face shields due to its high impact resistance.

Consumer Goods

Items like CDs, DVDs, and some household products utilize polycarbonate for its durability and clarity.