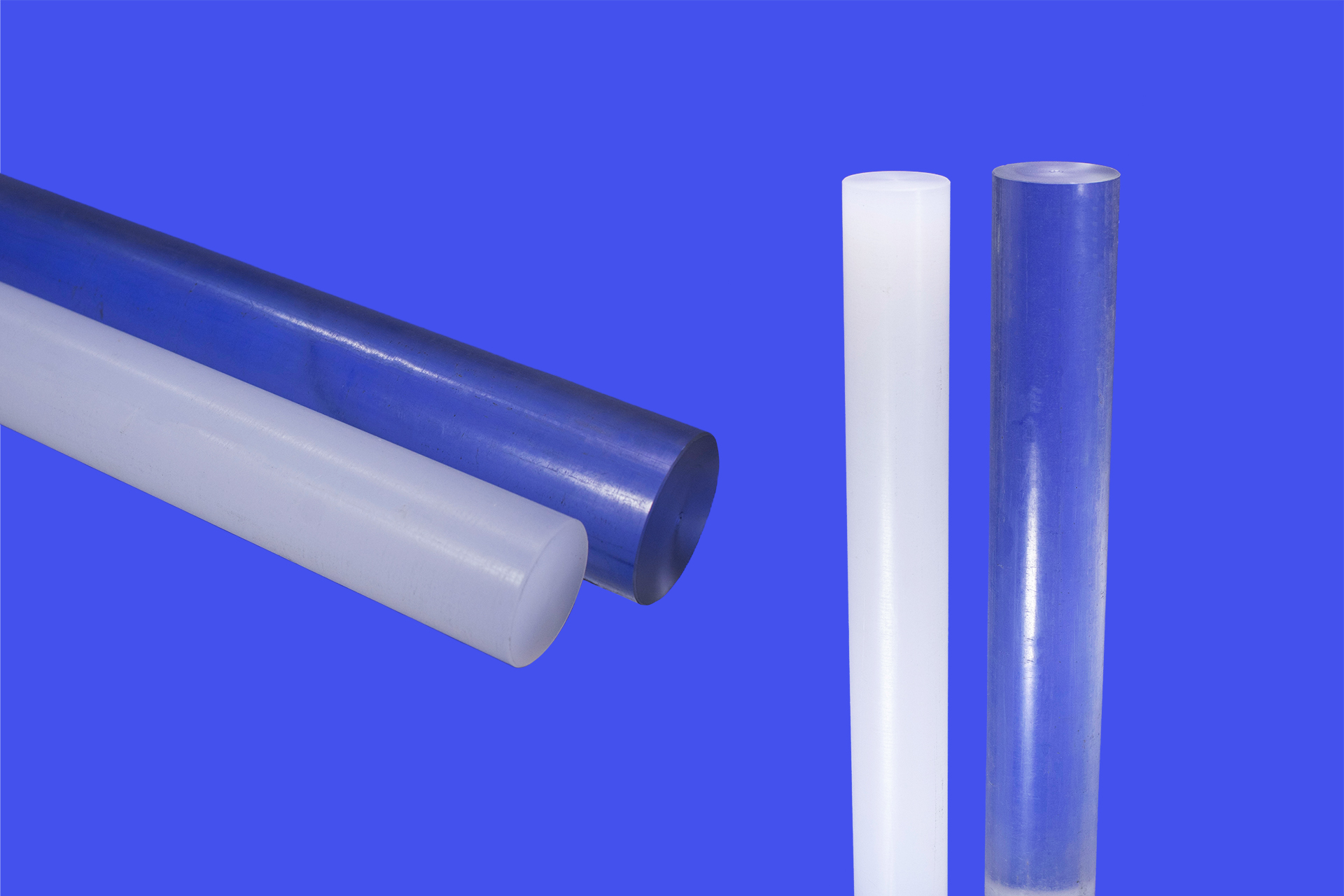

Polymat PCTFE

Polychlorotrifluoroethylene (PCTFE) is a high-performance thermoplastic renowned for its exceptional chemical resistance, low permeability, and thermal stability. PCTFE excels in demanding applications across a range of industries, including aerospace, pharmaceuticals, electronics, and industrial sectors, thanks to its distinctive properties.

Mechanical Properties

- Tensile strength : PCTFE typically has a tensile strength of approximately 20 to 30 MPa (megapascals) or 2,900 to 4,350 psi (pounds per square inch). This value reflects its capability to withstand moderate forces without fracturing.

- Impact Resistance: The material exhibits moderate impact resistance. Its Izod impact strength is generally between 10 and 30 J/m (joules per meter) or 0.5 to 1.5 ft-lbf/in. While it is not as impact-resistant as some other polymers, it is sufficient for applications where moderate impact resistance is needed.

- Modulus of Elasticity: PCTFE has a modulus of elasticity in the range of 1.5 to 2.0 GPa (gigapascals) or about 220 to 290 ksi (kilopounds per square inch). This indicates its rigidity and its ability to maintain shape under mechanical stress.

- Flexural Strength: The flexural strength of PCTFE is typically between 30 and 50 MPa (megapascals) or approximately 4,350 to 7,250 psi. This property denotes its resistance to bending and deformation under load.

- Creep Resistance: PCTFE demonstrates good creep resistance, maintaining its shape and mechanical properties under prolonged stress. This makes it suitable for applications requiring long-term dimensional stability.

- Dimensional Stability: The material has excellent dimensional stability with minimal shrinkage or warping, due to its low coefficient of thermal expansion.

- Fatigue Resistance: PCTFE exhibits reasonable fatigue resistance, allowing it to endure repeated stress cycles without significant performance degradation.

Thermal Properties

- Glass Transition Temperature (Tg): PCTFE has a relatively low glass transition temperature of approximately -100°C to -110°C (-148°F to -166°F). This indicates that PCTFE remains in a flexible, glassy state even at very low temperatures.

- Melting Temperature (Tm): PCTFE does not have a distinct melting point but rather a range where it transitions from a solid to a rubbery state. The polymer starts to soften around 220°C to 250°C (428°F to 482°F), depending on the specific formulation and processing conditions.

- Continuous Service Temperature: PCTFE can be used continuously at temperatures up to about 80°C to 100°C (176°F to 212°F) without significant degradation. This range indicates that it maintains its mechanical properties and dimensional stability at moderate temperatures.

- Thermal Decomposition Temperature: PCTFE begins to decompose at temperatures above 300°C (572°F). It has good thermal stability during processing and in applications where exposure to high temperatures is intermittent.

- Thermal Stability: The material demonstrates excellent thermal stability, maintaining its properties across a broad temperature range. It performs well in environments that experience significant thermal fluctuations.

- Thermal Expansion: PCTFE has a low coefficient of thermal expansion, meaning it experiences minimal dimensional changes with temperature variations. This contributes to its dimensional stability and accuracy in precision applications.

- Thermal Cycling Resistance: PCTFE exhibits good resistance to thermal cycling, allowing it to withstand repeated heating and cooling cycles without significant impact on its performance.

Chemical Properties

- Acids: PCTFE exhibits excellent resistance to a broad range of acids, including both dilute and concentrated forms of hydrochloric acid, sulfuric acid, and nitric acid. It maintains its chemical integrity and performance even when exposed to acidic conditions.

- Bases: The material also shows good resistance to bases, including sodium hydroxide and potassium hydroxide, even in concentrated solutions. PCTFE does not degrade significantly when exposed to alkaline environments.

- Solvents: PCTFE is highly resistant to many organic solvents, such as alcohols, ketones, and esters. It performs well in environments where exposure to solvents like acetone or ethanol is common. However, it is less resistant to some aggressive solvents, such as methylene chloride and certain chlorinated hydrocarbons.

- Oxidizing Agents: PCTFE has moderate resistance to oxidizing agents, including hydrogen peroxide and chlorine solutions. While it can handle exposure to these agents, prolonged contact with strong oxidizers may lead to degradation.

- Hydrolysis: PCTFE is resistant to hydrolysis, making it suitable for use in humid environments and under steam conditions. It maintains its chemical strength and performance in the presence of moisture.

- Fuel and Oils: The material demonstrates strong resistance to fuels, lubricating oils, and other hydrocarbon-based substances, which makes it suitable for applications in the automotive and industrial sectors where such exposure is common.

- Detergents and Cleaning Agents: PCTFE is resistant to many common detergents and cleaning agents, allowing it to withstand frequent cleaning processes without significant degradation.

Application Applications

- Aerospace: Utilized in aerospace components such as seals, gaskets, and structural parts where resistance to extreme conditions and chemicals is crucial. Its low outgassing properties make it suitable for use in spacecraft and satellite components.

- Chemical Processing: Employed in valves, pump linings, and reactor components due to its resistance to a wide range of chemicals, including acids, bases, and solvents. It helps prevent contamination and degradation in aggressive chemical environments.

- Semiconductor Manufacturing: Used in components and equipment for semiconductor fabrication, such as gas handling systems and vacuum seals, because of its low outgassing and chemical resistance.

- Pharmaceuticals: Applied in the manufacture of components for pharmaceutical processing and handling, including seals, gaskets, and tubing, due to its ability to resist various chemicals and maintain purity.

- High-Purity Applications: Suitable for use in high-purity environments where contamination must be avoided, such as in the production of high-purity gases and chemicals. PCTFE's low permeability to gases and liquids makes it ideal for these applications.

- Electronics: Used in electronic components like insulators and connectors that require chemical resistance and stability under varying conditions.

- Oil and Gas: Employed in seals and gaskets for oil and gas exploration and production equipment due to its resistance to hydrocarbons and harsh environmental conditions.

- Medical Devices: Utilized in certain medical devices and applications where chemical resistance and sterilization are important, including in components that come into contact with various chemicals and fluids.