Engineering Plastics: Shaping a Sustainable Future in Environmental Protection

The environmental protection industry, encompassing water treatment, air pollution control, and waste management, demands materials that are both durable and corrosion-resistant. Engineering plastics are increasingly finding their place in this sector due to their properties that contribute to a cleaner and healthier environment:

Corrosion Resistance:

Unlike metals, many engineering plastics are naturally resistant to corrosion from water, chemicals, and harsh environmental conditions. This ensures the longevity of equipment used in water treatment plants, air pollution control systems, and waste management facilities.

Low Friction:

Some engineering plastics offer low friction coefficients, reducing wear and tear on components in water treatment plants and waste handling equipment, leading to smoother operation and potentially lower maintenance needs.

Lightweight:

Compared to traditional materials like metal, engineering plastics offer significant weight reduction in certain components. This can be beneficial for specific applications in water treatment or waste management.

Chemical Resistance:

Certain engineering plastics exhibit excellent resistance to a wide range of chemicals used in water treatment processes and waste management, minimizing degradation and ensuring the integrity of equipment.

Abrasion Resistance:

Specific plastics demonstrate excellent abrasion resistance, minimizing wear from materials like sand or waste particles, extending the lifespan of equipment used in waste management and water treatment.

These properties translate to several advantages for the environmental protection industry:

Enhanced Equipment Durability:

Corrosion resistance and chemical resistance minimize equipment degradation, leading to longer lifespans and lower replacement costs.

Improved Efficiency:

Lower friction in certain components can potentially contribute to smoother operation and potentially lower energy consumption in treatment plants.

Reduced Maintenance Needs:

Abrasion resistance and wear resistance minimize the need for frequent replacements and repairs of critical components.

Lightweight Advantages:

In specific applications, lighter weight components can offer advantages in terms of handling or transportability within treatment or waste management facilities.

In conclusion, engineering plastics are playing a vital role in environmental protection by enabling the development of durable, corrosion-resistant equipment for water treatment, air pollution control, and waste management. They contribute to a more sustainable future by promoting longer equipment lifespans, potentially lower maintenance needs, and potentially improved efficiency in treatment processes.

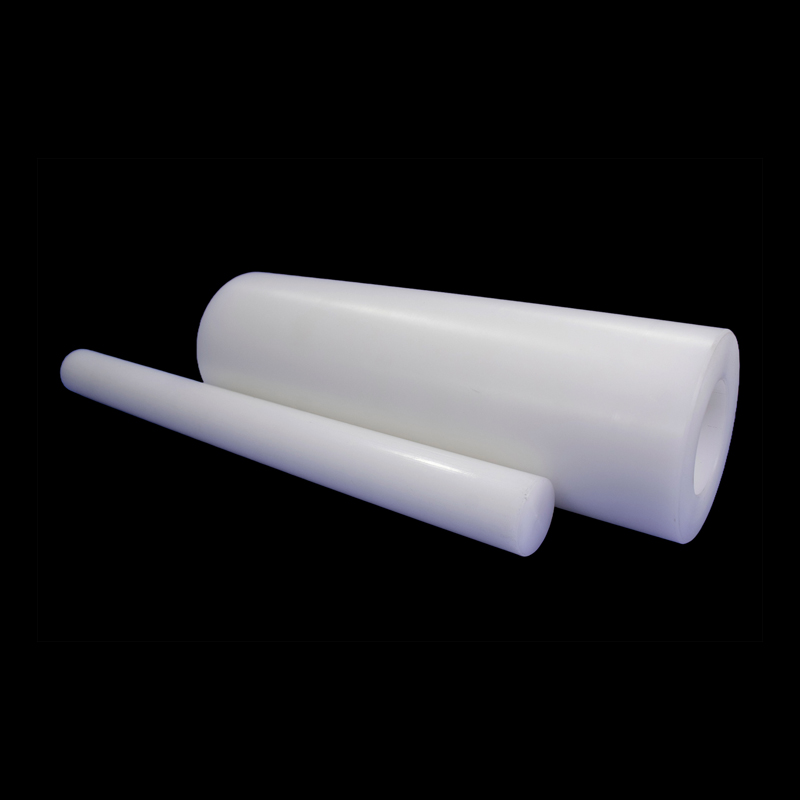

Materials list