Engineering Plastics in Machine Building: A Boon for Efficiency

Machine building encompasses a vast array of industries, from textile and printing to packaging and general machinery. Engineering plastics have become a game-changer in this sector due to their unique combination of properties:

Lightweight:

Compared to traditional materials like metal, engineering plastics offer significant weight reduction. This translates to lighter machines, improved energy efficiency, and easier handling.

Corrosion Resistance:

Unlike metals, many engineering plastics are naturally resistant to rust and corrosion, eliminating the need for expensive coatings and extending machine lifespan.

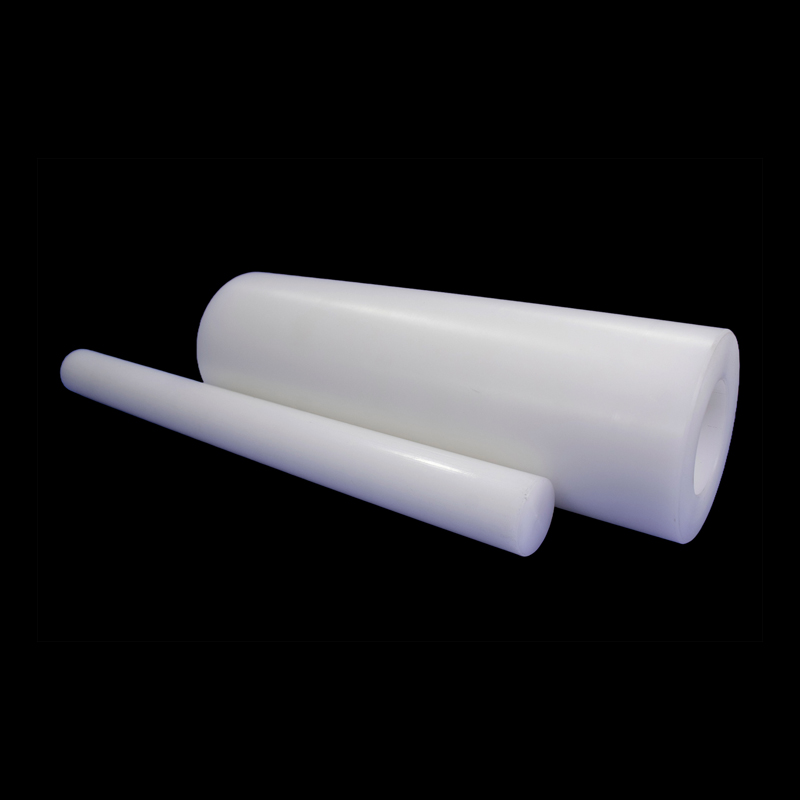

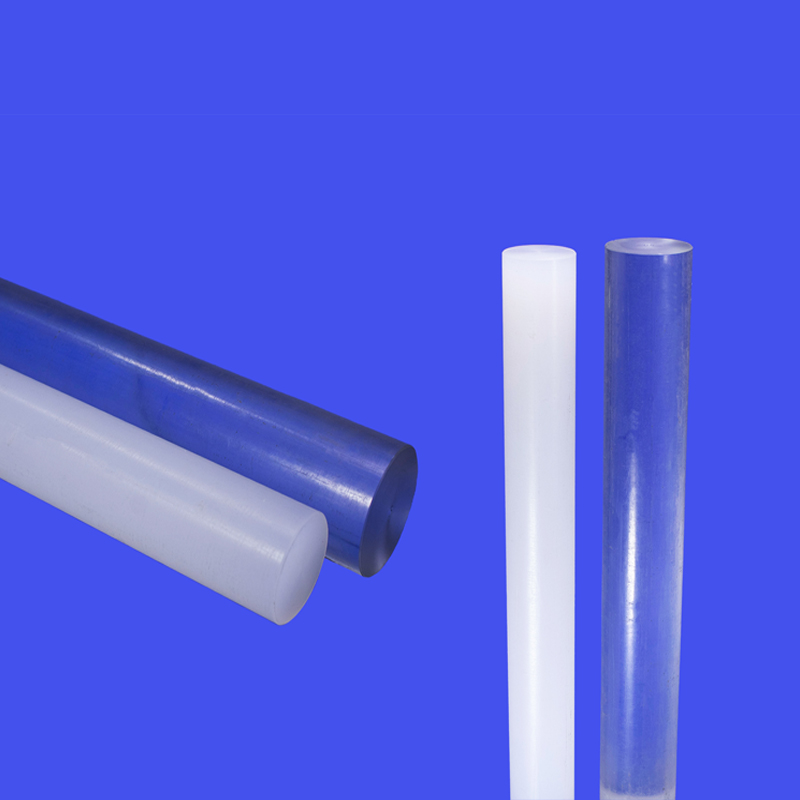

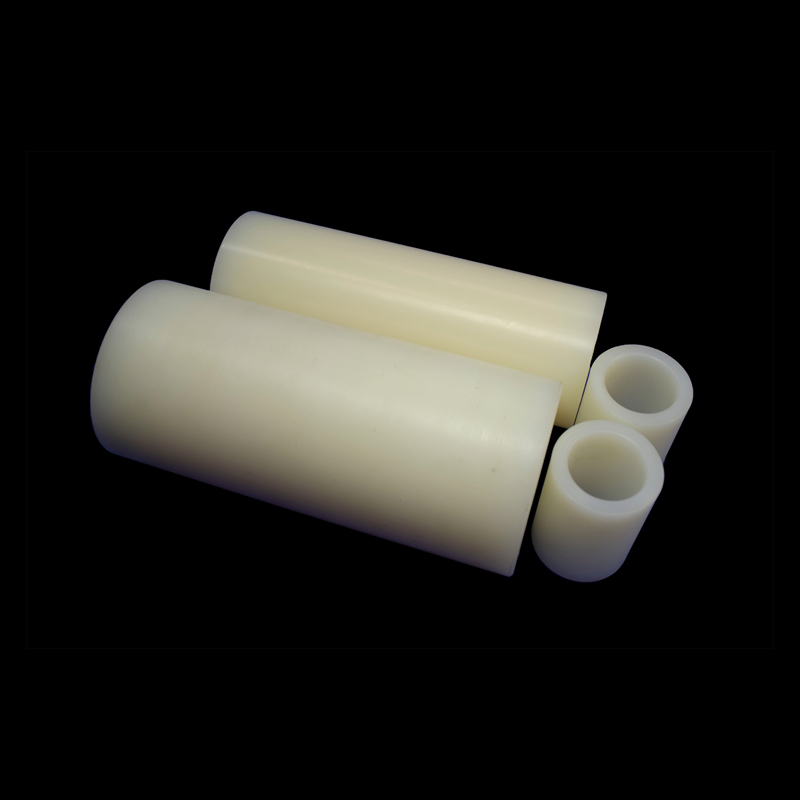

Design Flexibility:

Engineering plastics come in a wide variety of shapes, sizes, and colors, allowing for greater design freedom and customization in machine components.

High Strength and Wear Resistance:

Certain engineering plastics offer exceptional strength-to-weight ratios, making them suitable for demanding applications while remaining lightweight. Additionally, their wear resistance minimizes friction and maintenance needs.

Cost-Effectiveness:

While the initial cost per unit weight might be higher than metal, factors like lighter weight, lower maintenance, and longer lifespan contribute to a lower total cost of ownership for machines built with engineering plastics.

These benefits translate to several advantages for the machine building industry:

Improved Machine Performance:

Lighter machines with reduced friction translate to smoother operation, higher energy efficiency, and potentially increased production speeds.

Reduced Maintenance Costs:

Corrosion resistance and wear resistance lead to less downtime and lower maintenance costs.

Cost Savings:

While the initial material cost might be higher, the overall cost of ownership becomes lower due to the benefits mentioned above.

Design Innovation:

The design flexibility allows for the creation of more complex and functional machines.

Overall, engineering plastics are revolutionizing the machine building industry by enabling lighter, more efficient, and cost-effective machines with greater design freedom.

Materials list