Engineering Plastics: Keeping the Material Flowing Smoothly in Material Handling

Material handling encompasses the movement, storage, and control of materials throughout a production or distribution process. Engineering plastics have become a workhorse in this industry due to their properties that optimize material flow:

Low Friction:

Certain engineering plastics offer low friction coefficients, reducing wear and tear on conveyor belts, gears, and other components, ensuring smooth material movement.

High Impact Resistance:

They can withstand significant impacts and abuse common in material handling environments, minimizing breakage and downtime.

Dimensional Stability:

They maintain their shape well under varying temperatures and loads, ensuring consistent performance in material handling systems.

Lightweight:

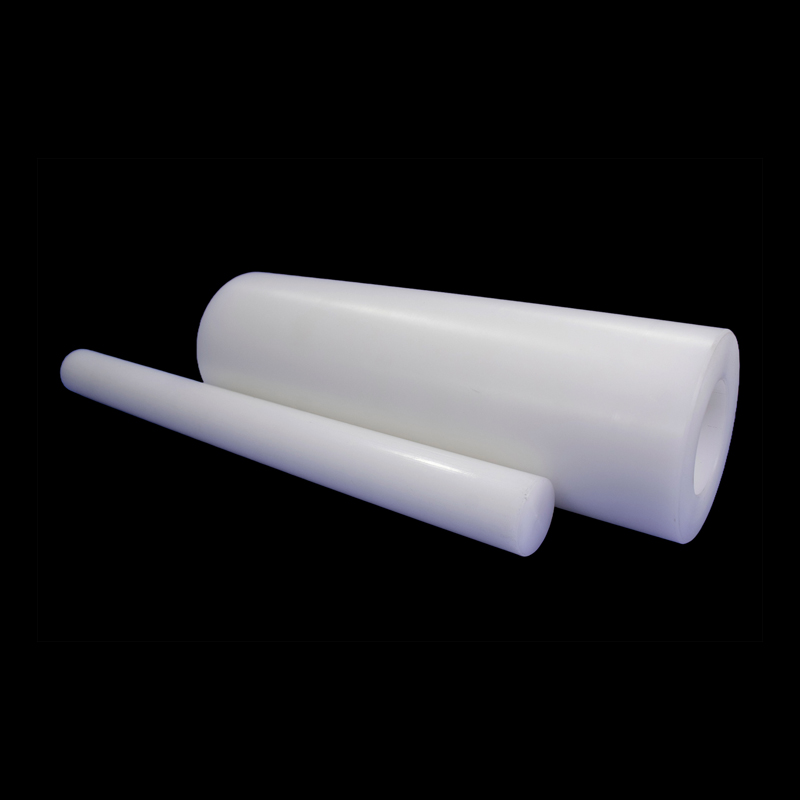

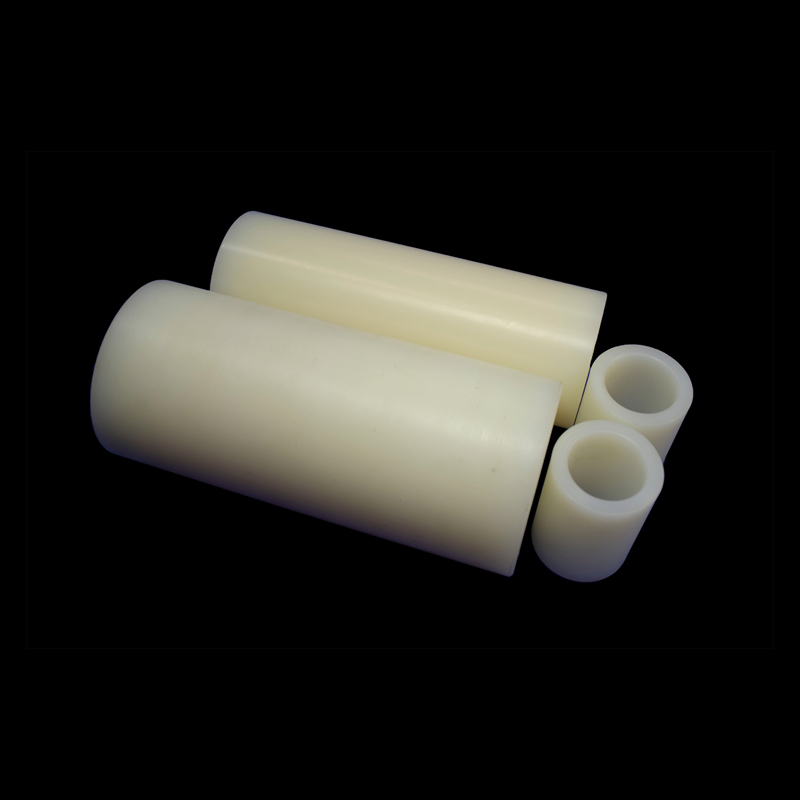

Compared to metal, engineering plastics offer significant weight reduction in components like rollers and containers, leading to easier handling and potentially lower energy consumption.

Corrosion Resistance:

Unlike steel, many engineering plastics are naturally resistant to rust and corrosion, eliminating the need for painting and extending equipment lifespan in harsh environments.

These properties translate to several advantages for the material handling industry:

Reduced Wear and Tear:

Low friction and high impact resistance minimize component wear and breakage, leading to less downtime and maintenance costs.

Improved Efficiency:

Smooth material flow due to low friction contributes to efficient operation and potentially increased throughput.

Lower Energy Consumption:

Lighter weight components can lead to lower energy use in conveying and handling systems.

Versatility:

Engineering plastics come in a variety of shapes and properties, allowing for customization to specific material handling needs.

Cost Savings:

While the initial cost per unit weight might be higher than metal, the benefits of lower maintenance, longer lifespan, and potentially lower energy use contribute to a lower total cost of ownership.

Overall, engineering plastics are transforming the material handling industry by enabling smoother, more efficient, and cost-effective material flow with increased system uptime and versatility.

Materials list