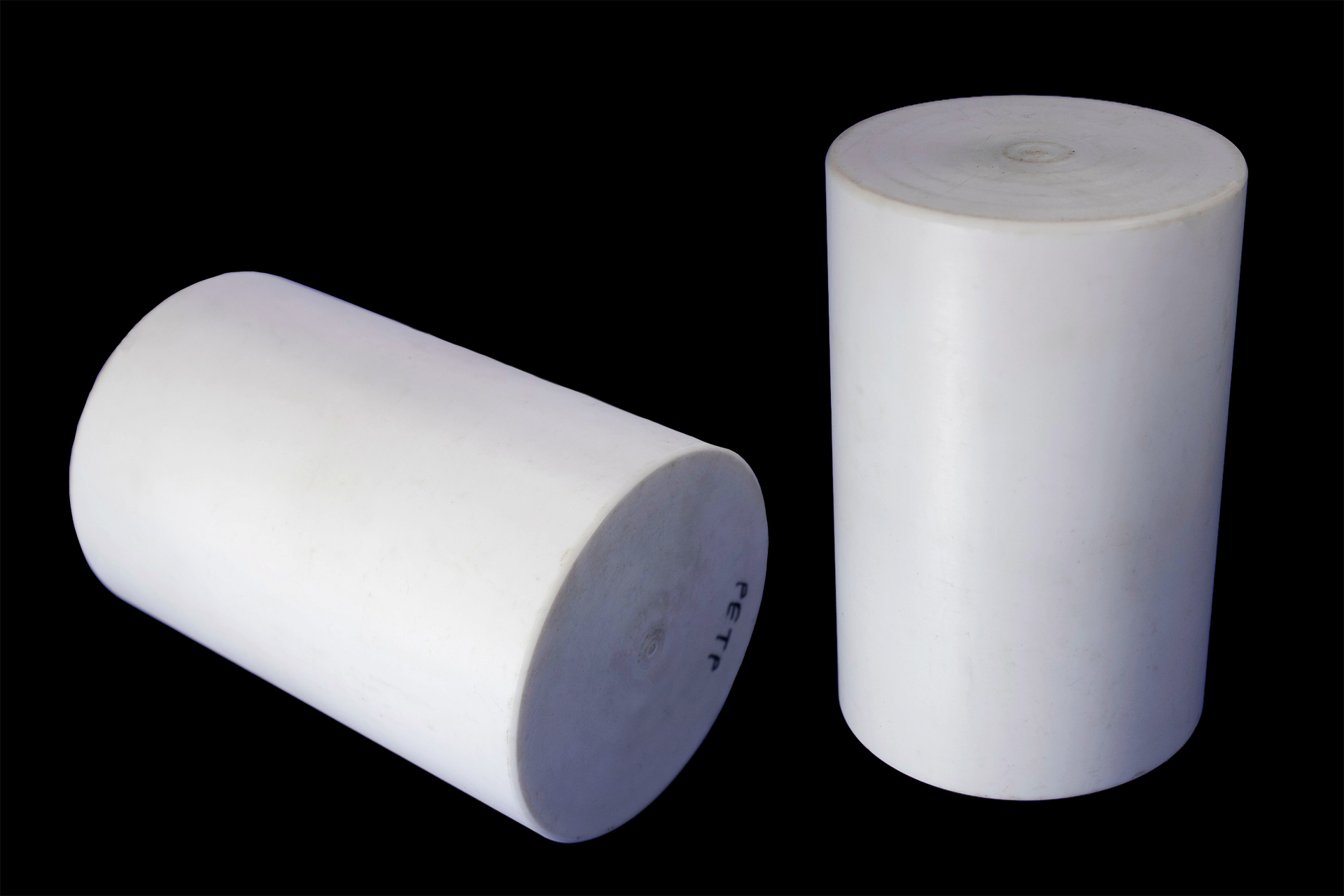

Polymat PETP, PET

Polyethylene Terephthalate (PETP) also known as PET is a high-performance thermoplastic polyester known for its strength, thermal stability, and chemical resistance. It is widely used in various industries due to its balanced properties and versatility.

Mechanical Properties

- High Tensile Strength : Typically around 50 to 75 MPa, providing robust performance under stress and making it suitable for structural applications.

- Excellent Impact Resistance: Capable of withstanding significant impact forces without major deformation or failure.

- Superior Fatigue Resistance: Maintains performance and durability over repeated stress cycles, reducing the risk of material fatigue.

- Low Coefficient of Friction: Exhibits low friction characteristics, which minimizes wear in moving parts such as gears and bearings.

- High Modulus of Elasticity: Around 2.8 to 4.0 GPa, offering rigidity and stability under load for high-stress applications.

- Good Creep Resistance: Demonstrates resistance to deformation under constant load, ensuring long-term dimensional stability.

Thermal Properties

- Continuous Service Temperature: Effective up to approximately 120°C (248°F), with some grades offering higher thermal stability.

- Exceptional Thermal Stability: Maintains performance in high-temperature environments, with good resistance to thermal degradation.

- Low Thermal Expansion: Exhibits minimal thermal expansion, ensuring dimensional accuracy and stability in temperature fluctuations.

- High Glass Transition Temperature: Around 70°C (158°F), above which the material becomes more flexible while retaining its mechanical strength.

- Thermal Insulation Properties: Provides effective insulation against heat, helping to manage thermal conditions in various applications.

- Thermal Oxidative Stability: Generally stable in oxidative environments at moderate temperatures, though high temperatures may impact performance.

Chemical Properties

- Chemical Resistance: Highly resistant to a range of chemicals including acids, bases, and organic solvents, though not suitable for strong alkalis.

- Resilience to Corrosive Environments: Performs well in environments with moderate corrosive chemicals.

- Resistance to Hydrolysis: Shows good resistance to moisture and steam, maintaining mechanical properties under humid conditions.

- Non-reactivity: Generally stable with most chemicals, ensuring reliable performance in various environments.

- Durability in High-Temperature Chemical Environments: Retains chemical resistance at elevated temperatures, providing dependable performance in demanding conditions.

- Low Permeability: Has low permeability to gases and liquids, suitable for applications requiring containment.

Application Sectors

Packaging

Widely used in packaging materials such as bottles, films, and containers due to its strength, clarity, and chemical resistance.

Textiles

Applied in textile fibers and fabrics, including clothing and industrial textiles, benefiting from its durability and resistance to abrasion.

Automotive

Utilized in automotive components such as interior parts, trims, and under-the-hood components due to its mechanical strength and thermal stability.

Electronics and Electrical

Employed in electrical insulators, connectors, and housings due to its good electrical insulating properties and thermal stability.

Medical

Used in medical device components and packaging, where its chemical resistance and ability to withstand sterilization are advantageous.

Industrial Manufacturing

Applied in various industrial components such as gears, bearings, and seals, leveraging its strength and wear resistance.

Consumer Goods

Found in a range of consumer products, including household items and appliances, due to its versatility and durability.

Construction

Utilized in construction materials such as insulation and reinforcement products, benefiting from its mechanical properties and resistance to environmental factors.

Aerospace

Used in aerospace applications for components that require high strength, dimensional stability, and thermal performance.

Energy

Employed in energy sector applications, including components for renewable energy systems and storage solutions, due to its durability and resistance to environmental conditions.

Defense and Military

Applied in defense-related products and components where high performance and durability are required.

Semiconductors

Used in semiconductor manufacturing equipment and components, benefiting from its thermal stability and precision.