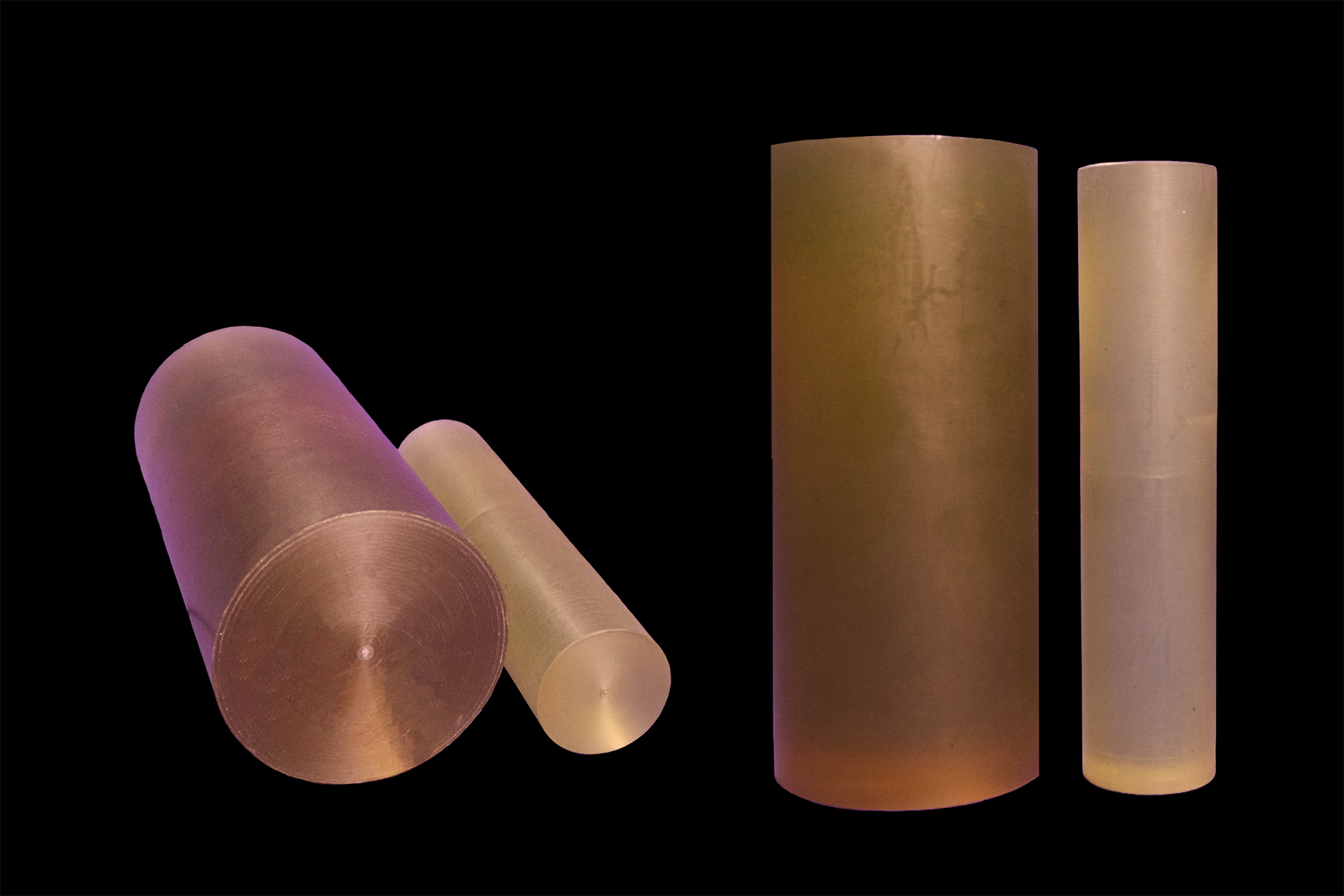

Polymat PSU, PPSU, PPS

Polysulfone (PSU) is a versatile high-performance thermoplastic distinguished by its exceptional mechanical strength, thermal stability, and chemical resistance. Its broad range of applications in medical, aerospace, automotive, and industrial sectors underscores its reliability and performance in demanding conditions. PSU’s ability to maintain its properties in harsh environments makes it a valuable material for advanced engineering solutions.

Mechanical Properties

- Tensile strength : Tensile strength of polysulfone ranges from approximately 70 to 85 MPa (10,000 to 12,000 psi). This value indicates the maximum stress the material can endure while being stretched or pulled before breaking, highlighting its durability and suitability for structural applications.

- Tensile modulus : The tensile modulus of polysulfone is between 2.4 and 3.4 GPa (350,000 to 500,000 psi). This property reflects the material's stiffness, with higher values signifying greater rigidity and resistance to deformation under tensile loads.

- Impact strength : In terms of impact strength, polysulfone exhibits an Izod impact strength (notched) ranging from 60 to 80 J/m (1.1 to 1.5 ft-lbf/in). This measure demonstrates its ability to withstand impact forces, indicating good toughness and resistance to crack propagation compared to other thermoplastics.

- flexural strength: For flexural strength, polysulfone typically shows values between 90 and 110 MPa (13,000 to 16,000 psi). This property reveals the material’s capacity to resist bending forces, making it effective in applications where bending resistance is crucial.

- flexural modulus : The flexural modulus of polysulfone ranges from 2.4 to 3.2 GPa (350,000 to 470,000 psi), which measures its stiffness when subjected to bending loads, indicating a high level of rigidity.

- Rockwell hardness : Polysulfone has a Rockwell hardness (M Scale) of about M80 to M90, indicating its resistance to indentation and providing insight into its overall hardness.

- Industrial components.

Thermal Properties

- Glass Transition Temperature (Tg): Approximately 190°C (374°F). Polysulfone retains its mechanical properties and performance at elevated temperatures due to its high Tg.

- Continuous Service Temperature: Can typically withstand continuous use at temperatures up to around 150°C (302°F) without significant degradation.

- Thermal Stability: Maintains structural integrity and mechanical strength over a broad temperature range, making it suitable for high-temperature applications.

- Thermal Decomposition: Begins to decompose at temperatures above 300°C (572°F). It remains stable under typical processing and operating conditions but should not be exposed to extreme temperatures for extended periods.

- Thermal Cycling: Exhibits good resistance to thermal cycling, meaning it can handle repeated heating and cooling without significant changes in its physical properties.

- Thermal Conductivity: Relatively low thermal conductivity compared to metals, which makes it effective as an insulating material in some applications.

Chemical Properties

- Acids: Good resistance to dilute and moderately concentrated acids, including sulfuric, hydrochloric, and nitric acids. Less resistant to highly concentrated acids over extended periods.

- Bases: Excellent resistance to strong bases, such as sodium hydroxide and potassium hydroxide. Maintains structural integrity and mechanical properties in concentrated alkaline solutions.

- Solvents: Resistant to a wide range of organic solvents, including alcohols, ketones, and esters. Withstands exposure to solvents like acetone, ethanol, and methanol. Limited resistance to some chlorinated hydrocarbons.

- Oxidizing Agents: Performs well against oxidizing agents, including hydrogen peroxide and chlorine solutions. Retains strength and stability under exposure to these chemicals.

- Hydrolysis: Relatively resistant to hydrolysis, making it suitable for humid environments and exposure to steam. Stability under high moisture conditions, though long-term exposure to high temperatures and moisture may impact properties.

Application Applications

- Medical Devices: Used in the manufacturing of surgical instruments, diagnostic equipment, and implants due to its biocompatibility, sterilization resistance, and high thermal stability.

- Water Filtration: Employed in membranes for water purification and treatment systems, including reverse osmosis and ultrafiltration, due to its excellent chemical resistance and high thermal stability.

- Automotive Industry: Utilized in components such as fuel system parts, electronic housings, and under-the-hood components that require high heat resistance and durability.

- Aerospace: Applied in aerospace components where high thermal resistance and mechanical strength are crucial, such as in cockpit displays and structural parts.

- Electronics: Used in electrical insulators, connectors, and housings for electronic devices due to its electrical insulating properties and thermal stability.

- Industrial Equipment: Found in various industrial applications, including gears, bearings, and pumps, where its wear resistance and thermal stability are advantageous.

- Food and Beverage Industry: Employed in equipment and containers where resistance to high temperatures and chemical cleaning agents is needed.

- Construction: Used in specialized construction applications such as high-performance seals, gaskets, and insulation materials due to its durability and resistance to environmental factors.