Engineering Plastics: Tough Solutions for Demanding Jobs in Heavy Equipment

The heavy equipment industry, encompassing agriculture, steel mills, mines, and construction, demands robust materials that can withstand harsh environments and heavy workloads. Engineering plastics are proving their worth in this sector due to their properties that meet these demanding applications:

High Strength and Wear Resistance:

Certain engineering plastics possess exceptional strength and wear resistance. This allows them to handle heavy loads, abrasive materials, and constant use in equipment like gears, bushings, and wear liners, without compromising performance.

Lightweight:

Compared to traditional metals, engineering plastics offer significant weight reduction. This translates to lighter components for construction equipment, agricultural machinery, and mining vehicles, potentially improving fuel efficiency, maneuverability, and reducing overall equipment weight.

Corrosion Resistance:

Unlike metals, many engineering plastics are naturally resistant to rust and corrosion from water, dust, and chemicals commonly encountered in heavy equipment operation. This minimizes component degradation and extends equipment lifespan.

Low Friction:

Specific engineering plastics offer low friction coefficients, reducing wear and tear on moving parts in equipment, leading to smoother operation and potentially lower energy consumption.

Noise Reduction:

Compared to metal components, some engineering plastics can help dampen noise and vibrations, contributing to a quieter work environment for operators.

These properties translate to several advantages for the heavy equipment industry:

Enhanced Equipment Durability:

High strength, wear resistance, and corrosion resistance minimize component wear and failure, leading to longer equipment lifespans and lower replacement costs.

Improved Efficiency:

Lighter weight components and lower friction can potentially contribute to improved fuel efficiency and smoother operation.

Reduced Maintenance Needs:

Wear resistance and low friction minimize the need for frequent replacements and lubrication of components.

Safer Operation:

Noise reduction can contribute to a safer and more comfortable work environment for heavy equipment operators.

In conclusion, engineering plastics are transforming the heavy equipment industry by enabling the development of durable, lightweight, and potentially more cost-effective equipment. Their contribution to wear resistance, corrosion resistance, and potentially lower maintenance needs keeps heavy equipment operational for longer, leading to a more efficient and productive industry.

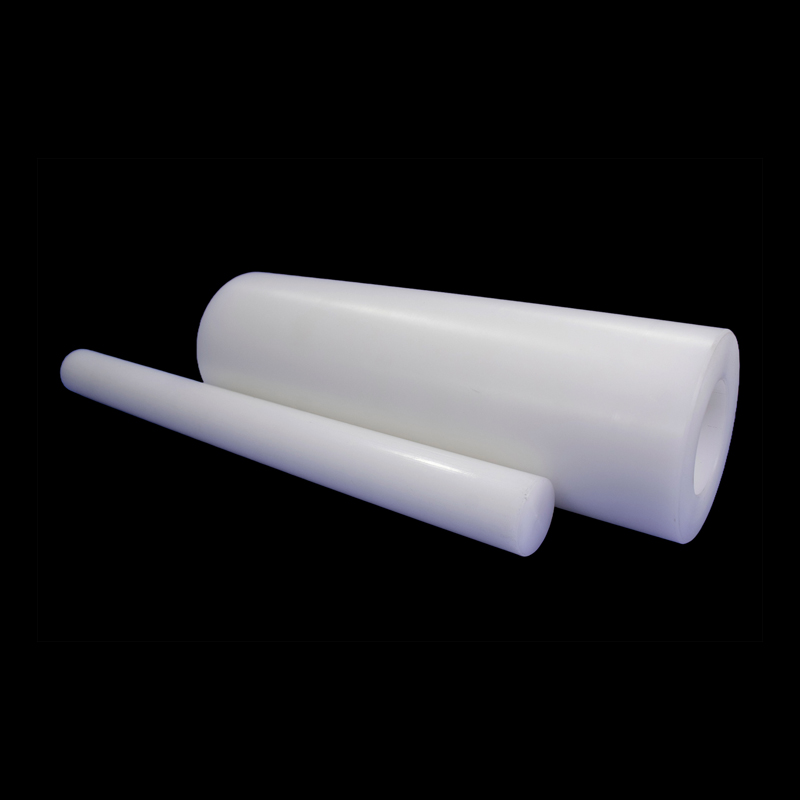

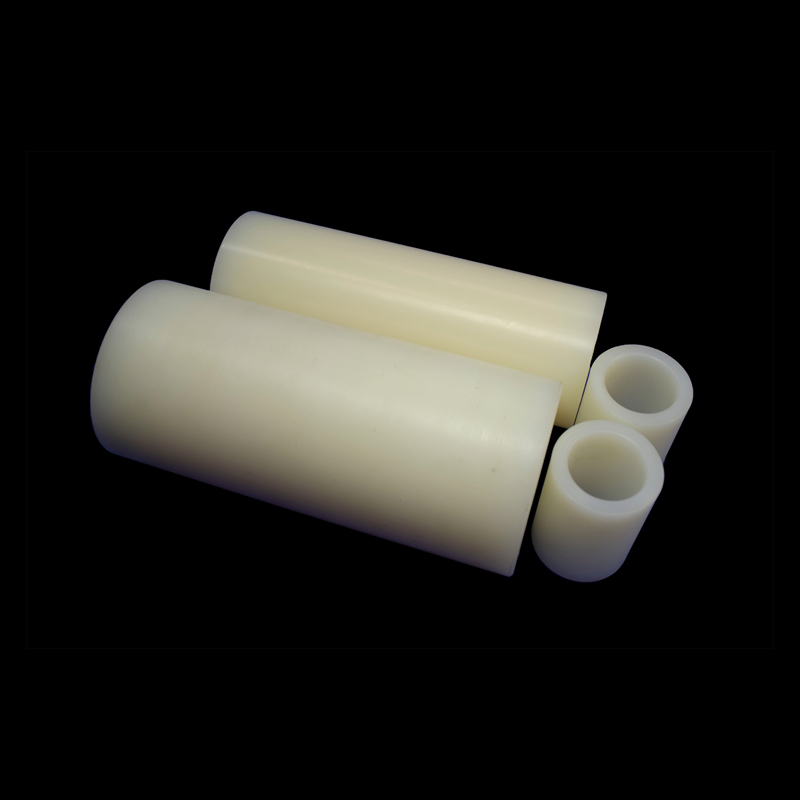

Materials list