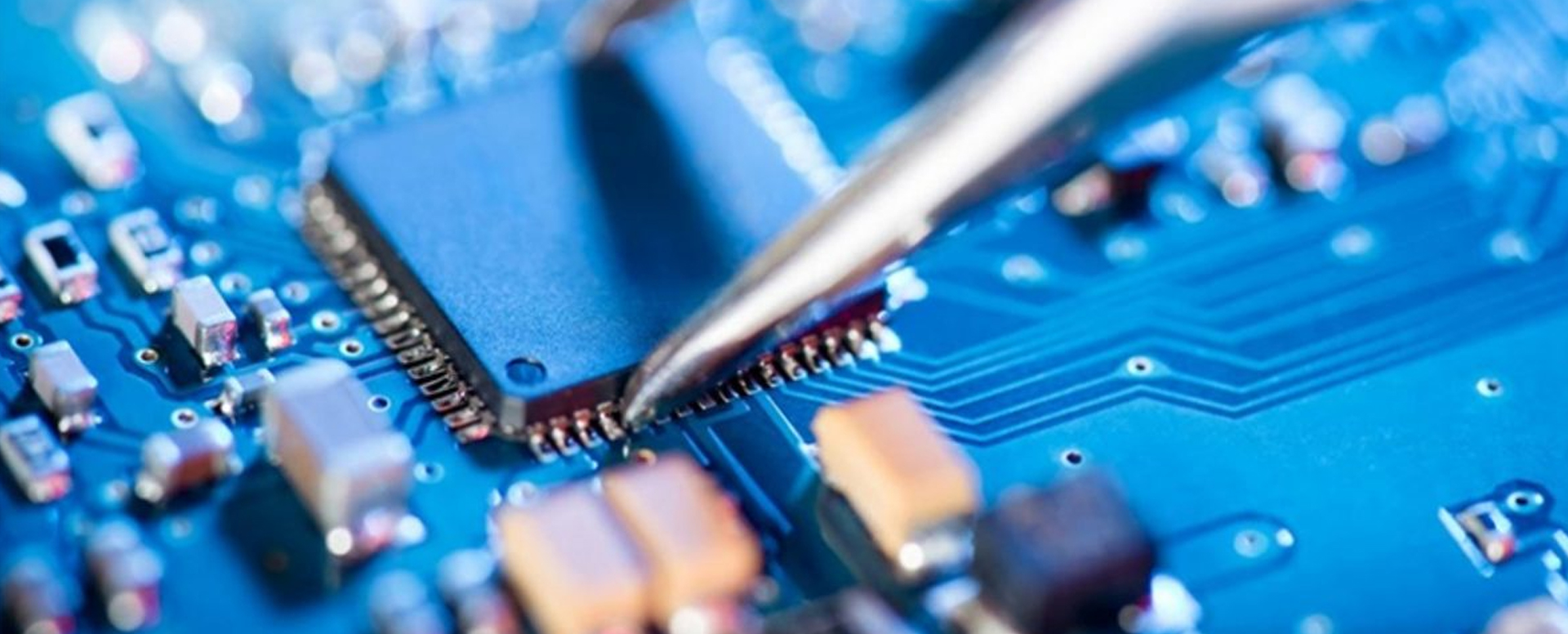

Engineering Plastics: Powering Up Electronics and Semiconductors

The electronics and semiconductor industries rely on materials that offer a unique blend of properties to ensure efficient performance and miniaturization. Engineering plastics have become a key player in this sector due to their ability to meet these demanding requirements:

Electrical Insulation:

Certain engineering plastics are excellent electrical insulators, preventing unwanted current flow and short circuits within delicate electronic components.

Dielectric Strength:

They possess high dielectric strength, allowing them to withstand high voltages without breaking down, crucial for reliable power delivery.

Dimensional Stability:

These materials maintain their shape well under varying temperatures, ensuring consistent performance and preventing warping or deformation that could disrupt electrical connections.

Flame Retardant Options:

Many engineering plastics are available with flame retardant properties, enhancing fire safety within electronic devices.

Lightweight:

Compared to metals, engineering plastics significantly reduce weight, making them ideal for miniaturized electronic components and portable devices.

Heat Resistance:

Certain engineering plastics offer good heat resistance, allowing them to handle the operating temperatures of electronic components without melting or degrading.

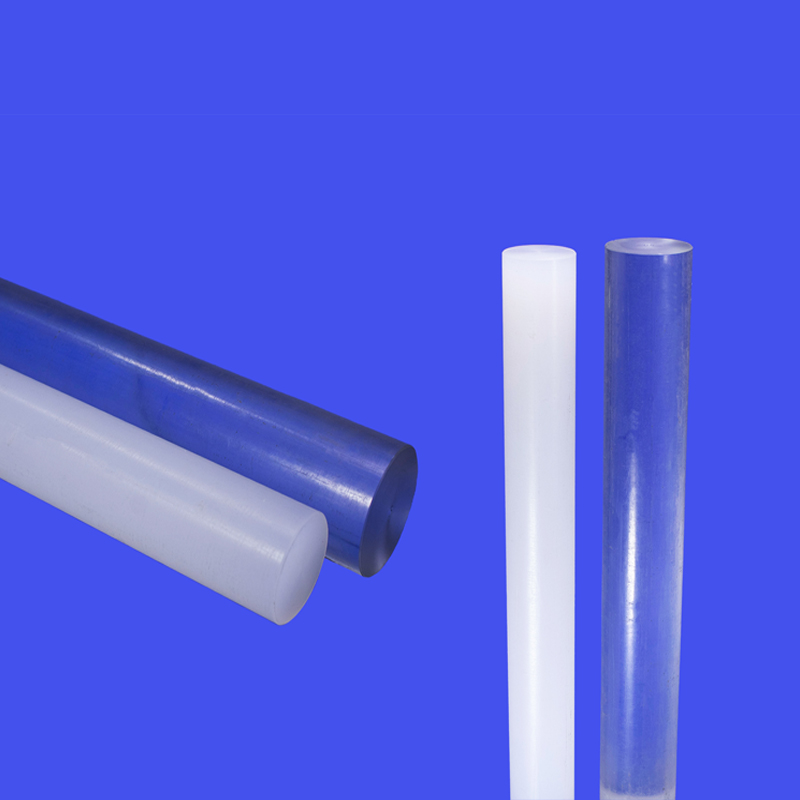

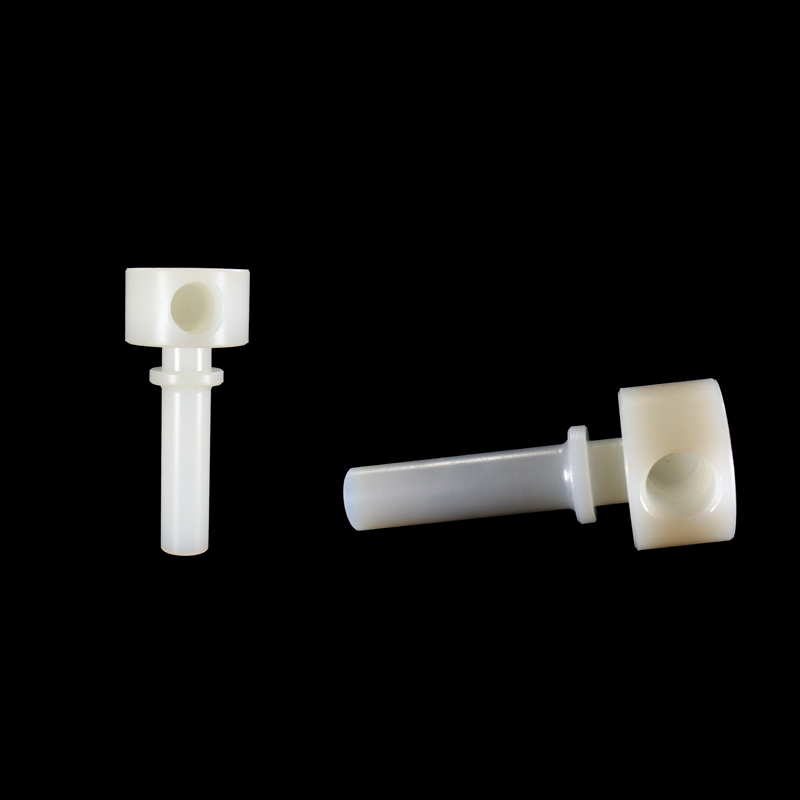

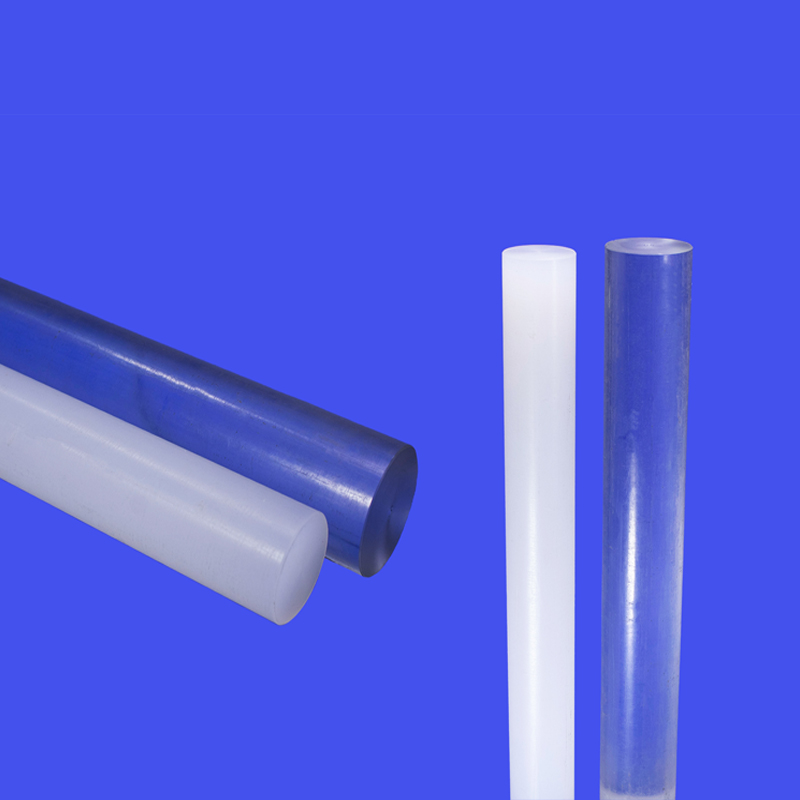

Machinability:

Many engineering plastics can be easily machined and molded into complex shapes, enabling intricate designs for electronic components and housings.

These properties translate to several advantages for the electronics and semiconductor industries:

Enhanced Fire Safety:

Flame retardant options minimize the risk of electrical fires in electronic devices.

Miniaturization Potential:

Lightweight and machinable plastics enable the development of smaller, more compact electronic devices.

Improved Reliability:

Electrical insulation, dielectric strength, and dimensional stability contribute to more reliable and consistent performance of electronic devices.

Cost-Effectiveness:

While the initial material cost might be higher than some traditional materials, the benefits of lighter weight, easier processing, and potentially longer lifespan can lead to a lower total cost of ownership for some devices.

Overall, engineering plastics are revolutionizing the electronics and semiconductor industries by enabling the creation of reliable, miniaturized, and potentially more cost-effective electronic devices

Materials list