Engineering Plastics: Strengthening Defense Capabilities with Lightweight Solutions

The defense industry demands materials that offer a balance of strength, weight reduction, and performance for a variety of applications. Engineering plastics are increasingly finding their place in this sector due to their properties that contribute to a tactical advantage:

Lightweight:

Compared to traditional metals, engineering plastics offer significant weight reduction. This translates to lighter vehicles, armor components, and soldier gear, leading to improved mobility, agility, and reduced fuel consumption in military vehicles.

High Strength-to-Weight Ratio:

Certain engineering plastics possess exceptional strength for their weight, making them suitable for demanding defense applications like ballistic protection components without compromising on mobility.

Corrosion Resistance:

Unlike metals, many engineering plastics are naturally resistant to corrosion from saltwater, sweat, and other environmental factors, minimizing equipment degradation and extending service life.

Electrical Insulation:

Specific types of engineering plastics offer good electrical insulation, crucial for protecting sensitive electronic components within military equipment.

Impact Resistance:

Certain plastics exhibit excellent impact resistance, potentially offering additional protection for equipment and personnel.

These properties translate to several advantages for the defense industry:

Enhanced Soldier Mobility and Agility:

Lighter weight equipment allows soldiers to maneuver more effectively on the battlefield.

Improved Operational Efficiency:

Lighter vehicles require less fuel, reducing logistical burdens and potentially increasing operational range.

Durability and Reduced Maintenance:

Corrosion resistance minimizes equipment degradation and the need for frequent replacements, leading to lower lifecycle costs.

Design Flexibility:

Engineering plastics allow for the creation of lightweight yet strong components with complex shapes, potentially leading to more ergonomic and functional designs for military equipment.

In conclusion, engineering plastics are making a significant impact in the defense industry by enabling lighter, more durable, and potentially more cost-effective equipment. Their contribution to soldier mobility, operational efficiency, and design flexibility strengthens overall defense capabilities.

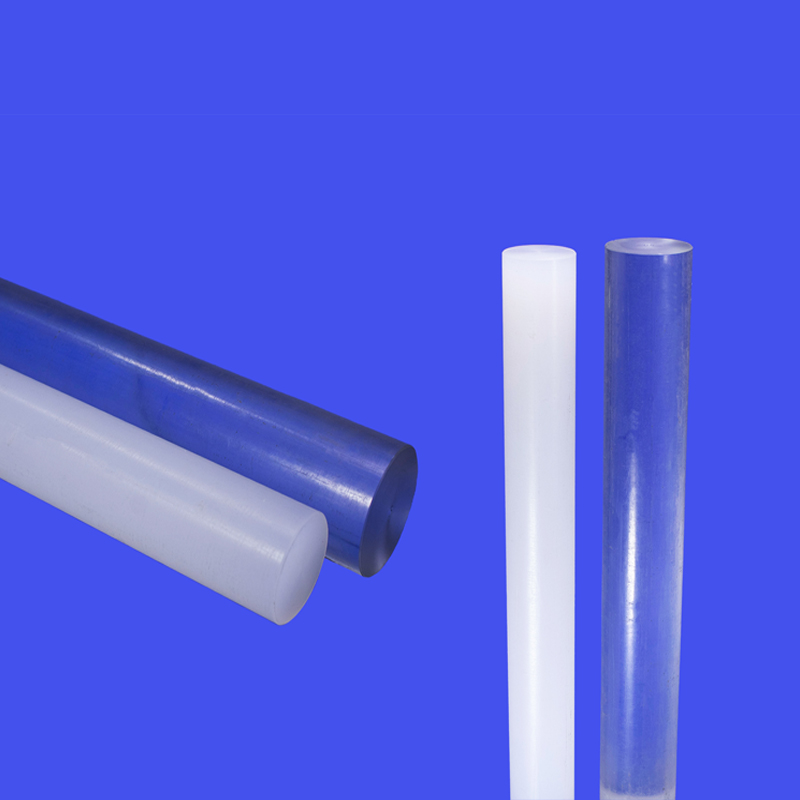

Materials list